Tool for dismantling tire locking collar

A dismantling tool and tire lock technology, which is applied in tire installation, tire parts, transportation and packaging, etc., can solve the problems of low work efficiency, time-consuming and labor-intensive, easy to damage tires, etc., and achieve the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

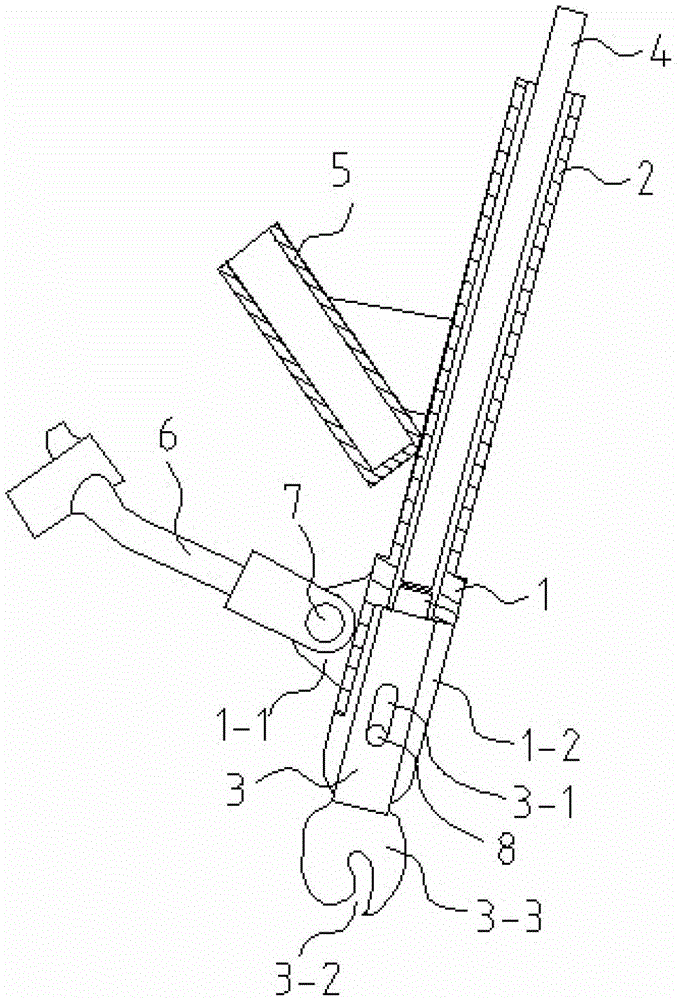

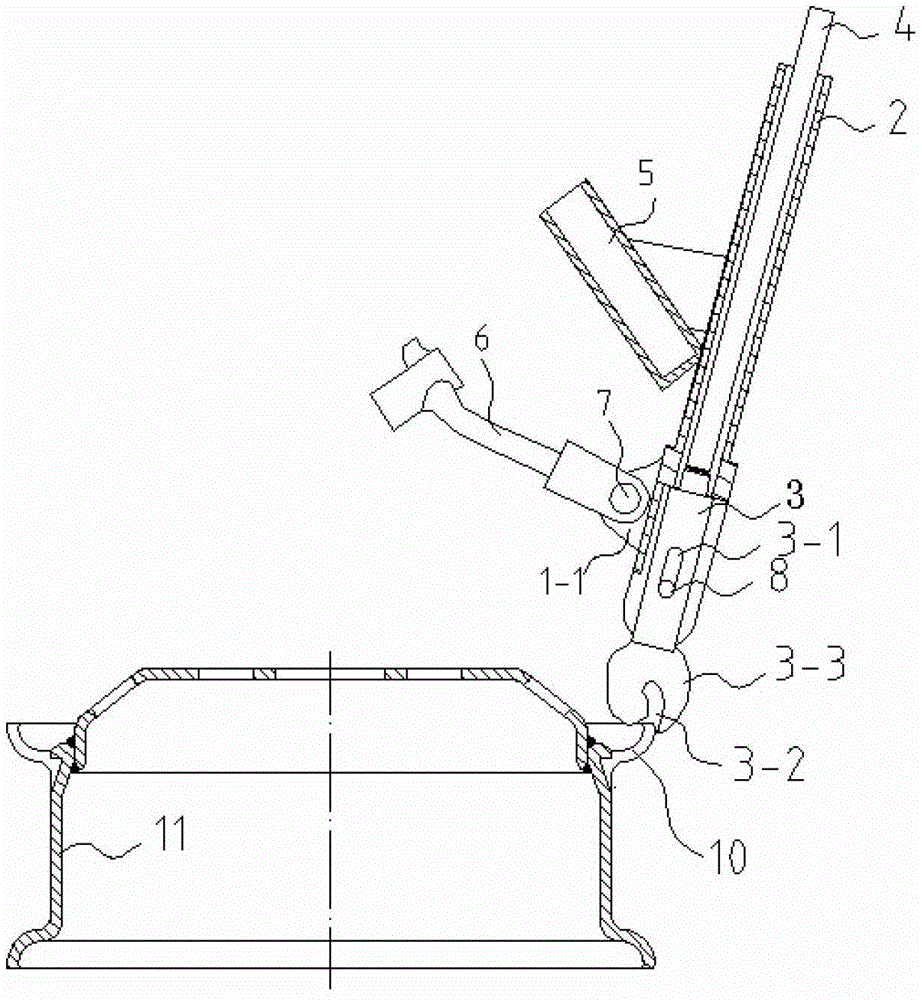

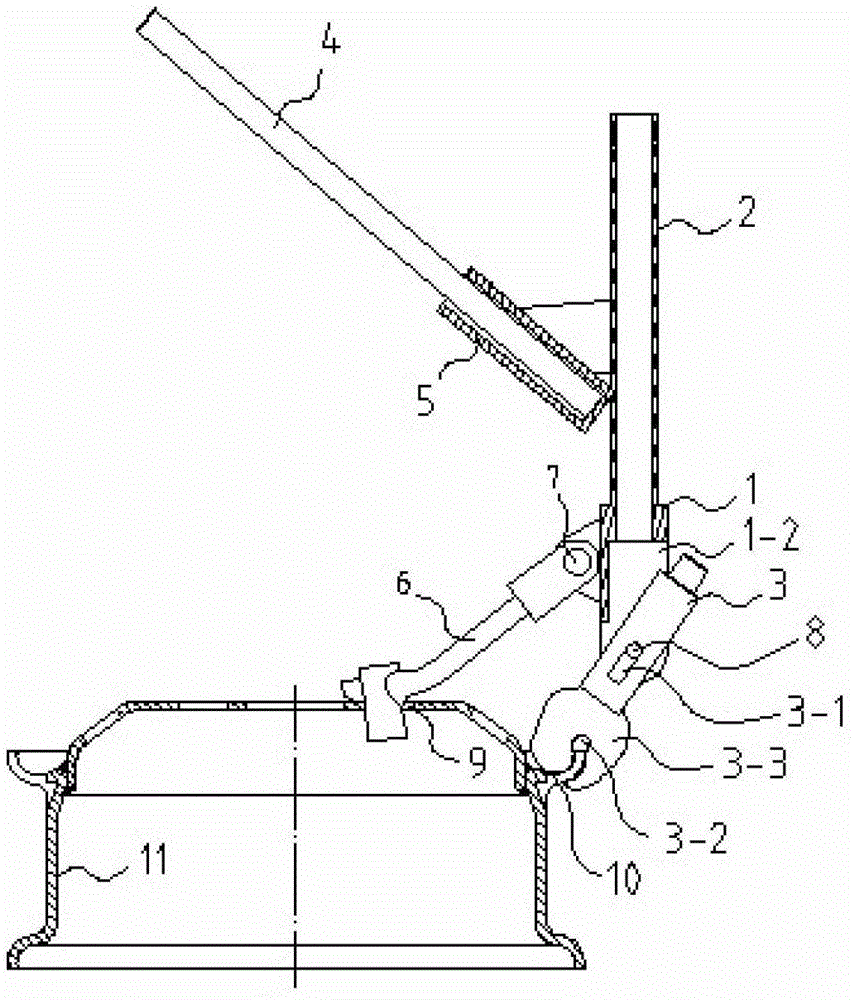

[0015] like figure 1 As shown, the tire lock ring removal tool of the present invention includes a main sleeve 1, an upper sleeve 2, a caliper assembly 3, a stamping rod 4, a side sleeve 5 and a support rod 6;

[0016] Wherein, the upper end of the outer wall on one side of the main sleeve 1 is provided with a support 1-1, and the lower end of the side wall on the other side has a gap 1-3, and the support rod 6 is connected to the support by the first pin 7. Seat 1-1 movable connection;

[0017] One end of the upper sleeve 2 is consolidated with the upper end of the main sleeve 1, and the side sleeve 5 is installed at the center of the outer wall of the upper sleeve 2 on the same side of the support 1-1,

[0018] The middle part of the caliper assembly 3 is provided with an oblong groove 3-1, and the lower end is provided on the caliper 3-3;...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap