3D modeling printing method

A technology for 3D modeling and printing nozzles, which is applied in the field of 3D object and supported object molding, and can solve the problems of not particularly high molding accuracy, time-consuming, and large equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific structures or parts targeted in the introduction process of the following embodiments are only used as reference examples for those skilled in the art to understand the present invention. Those skilled in the art can also design or copy them under the inspiration of the technical solutions described in the embodiments. Various equivalent or similar technical features that do not exceed the technical scope or technical essence of the present invention. Therefore, it is inappropriate to limit the scope of protection encompassed by the claims of the present invention with such exemplary descriptions. The technical solutions equivalent to or similar to the present invention still belong to the protection scope of the claims of the present invention.

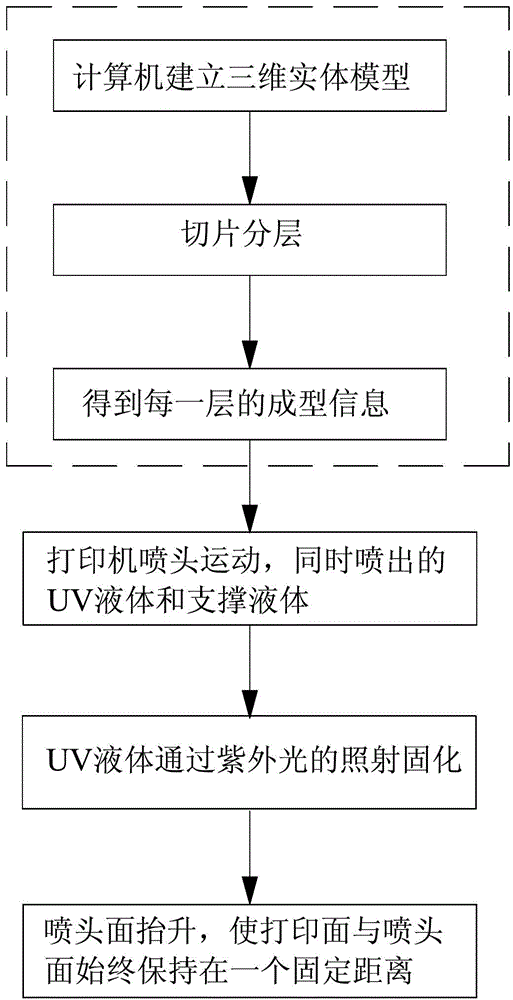

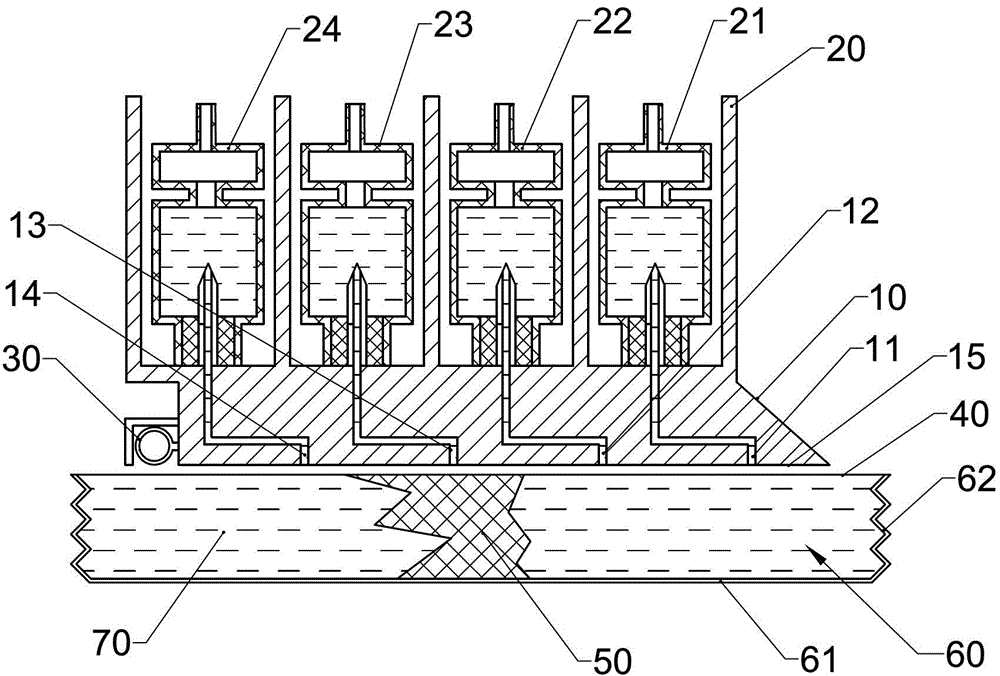

[0023] like figure 1 and figure 2 As shown, the embodiment of the three-dimensional modeling printing method includes the following steps:

[0024] The first step: establish a computer solid model of a three-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com