Material distribution method for particulate matter printing, and particulate matter printing method

A particle and cloth technology, which is applied in the field of particle printing cloth, can solve the problems of low efficiency of artificial cloth and inability to apply color printing, etc., and achieve the effect of color printing and fast printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

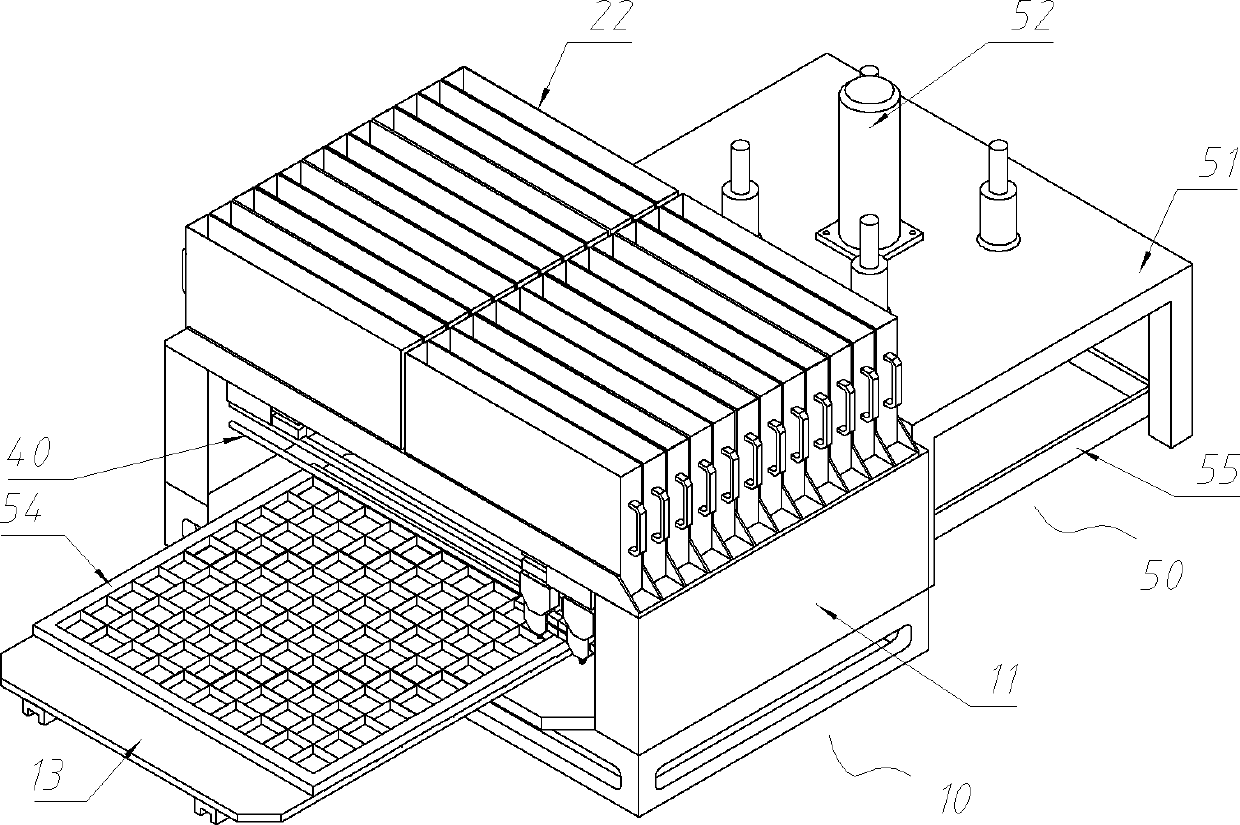

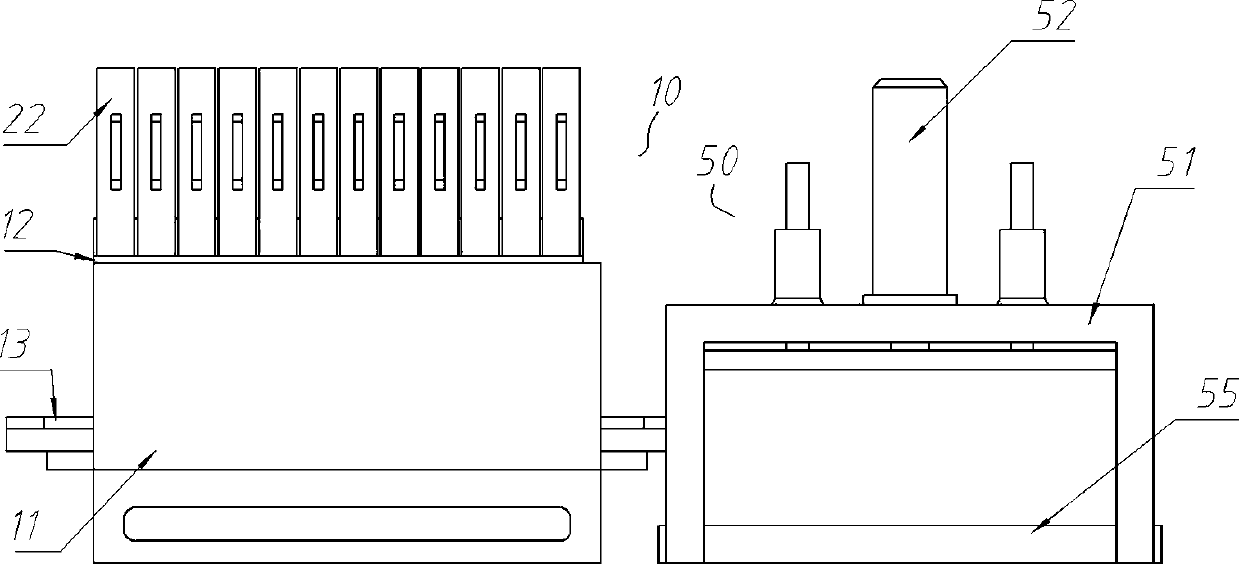

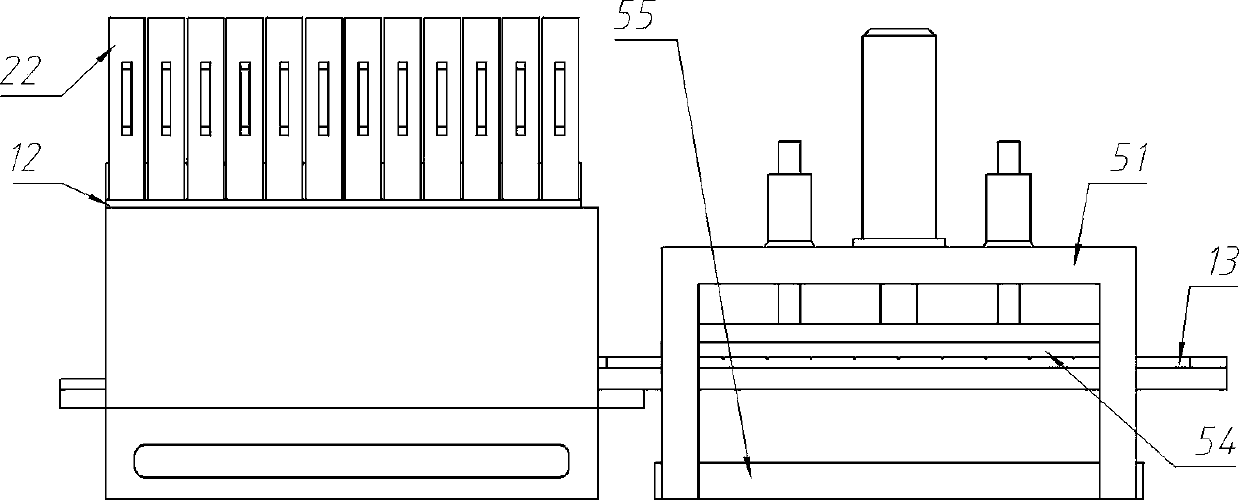

[0039] The present invention will be further described below in conjunction with accompanying drawing.

[0040] The particle printing in the present invention adopts the dry-wet separation method to separate the dry process from the wet process. The dry process is to print solid particles into design patterns, and the wet process is to solidify the printed design patterns.

[0041]Particle printing is a kind of physical printing. As the name implies, it is to print design patterns with granular objects. The granular pigments used in printing are solid particles, including pebbles, broken glass, waste brick slag, ceramsite, mosaic grains, colored sand and so on. According to the application, the surface shape of the picture can be granular or polished, and the printed picture materials are divided into inorganic and organic, mainly due to the different components of binders and additives. Inorganic refers to ordinary cement, colored cement, and peroxide powder. , ceramic powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com