Rolling adjusting roller device of fully-automatic computerized flat knitting machine

A computerized flat knitting machine, fully automatic technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve problems affecting the flat knitting machine, uneven fabric thickness, slow pulling, etc., to improve the application range and simplify the structure The effect of reasonableness, strong elasticity and reset ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

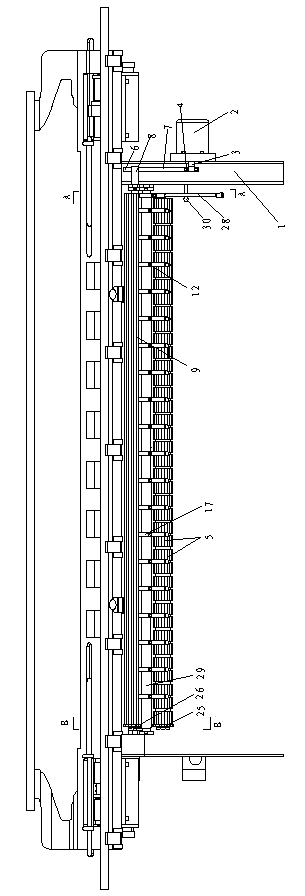

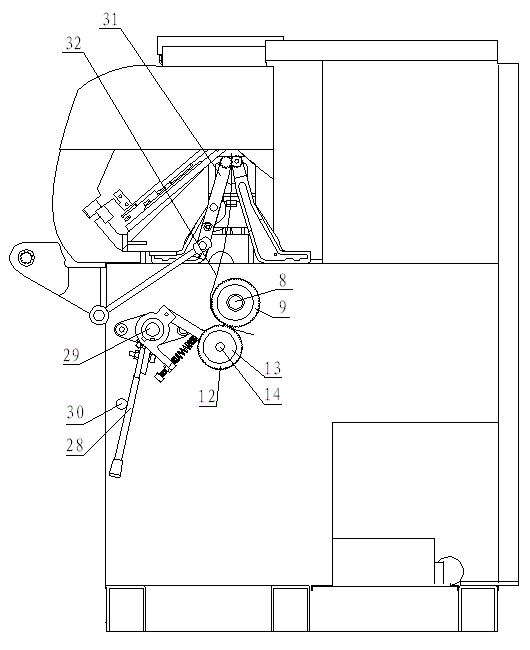

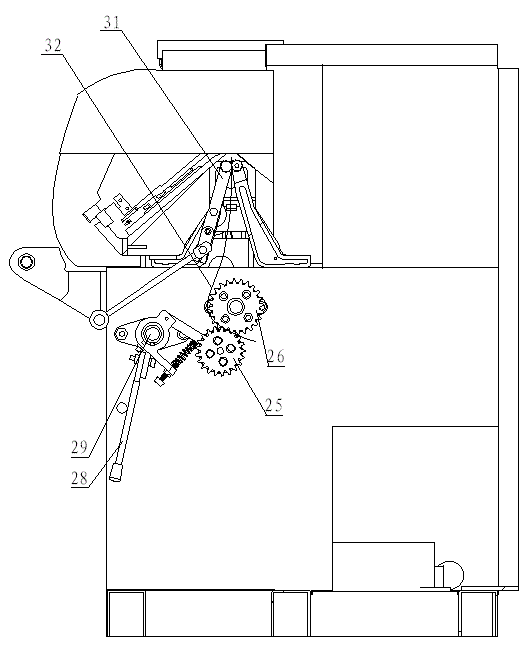

[0022] see Figure 1 to Figure 6 , the embodiment of the present invention fully automatic computer flat knitting machine is provided with: frame 1, motor 2, motor shaft 3, main sprocket 4, slave sprocket 6, chain 7, driving shaft 8, deck 30, high position roller device 31 , the motor 2 and the motor shaft 3 are installed as a whole, the motor 2 is fixed on the frame 1 with bolts, the main sprocket 4 is fixed on the motor shaft 3 with a fixed pin, and the two ends of the driving shaft 8 are covered with bearings and bushings. The two ends of the shaft 8 are fixed on the frame 1 through the bushing; the slave sprocket 6 is fixed on the driving shaft 8 with a fixed pin, the chain 7 is inserted into the main sprocket 4 and the slave sprocket 6 to connect it, and the card seat 30 is connected with the Rack 1 is welded and fixed.

[0023] The rolling adjustment roller device of this embodiment is provided with corrugated roller sleeve 9, roller 13, connecting shaft 14, swing frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com