Cloth roll leveling device

A leveling device and cloth roll technology, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of cloth surface wrinkles, textile product quality impact, etc., and achieve the effect of improving the quality of sewing processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

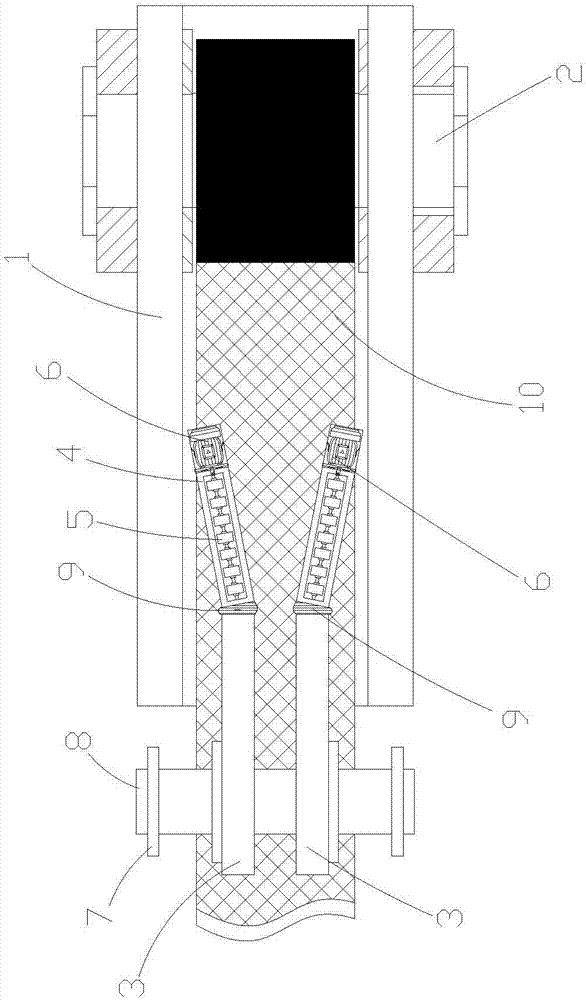

[0017] Such as figure 1 A cloth roll leveling device shown includes a cloth guide table 1, a cloth release roller 2, a first support 3, a second support 4, a leveler frame 7 and a central axis 8, and the cloth release roller 2 passes through The bearing is rotatably installed on the left end of the cloth guide table 1, the central axis 8 is installed on the first bracket 3, the two first brackets 3 are parallel and fixedly installed on the central axis 8, and the two second brackets 4 are installed obliquely on the two sides respectively. The front end of a first bracket 3, and two second brackets 4 are set to a wide-mouth structure near one end of the cloth releasing roller 2, and the second bracket 4 is equipped with a leveling wheel 5 through a transmission shaft, on the second bracket 4 A driving motor 6 is also provided, and the transmission shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com