Tabbed separation clutch plate

A clutch plate and separator technology, used in clutches, friction clutches, fluid-driven clutches, etc., to solve problems such as multi-plate clutch drag and rotation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The following description is merely exemplary in nature and is not intended to limit the invention, its application or uses.

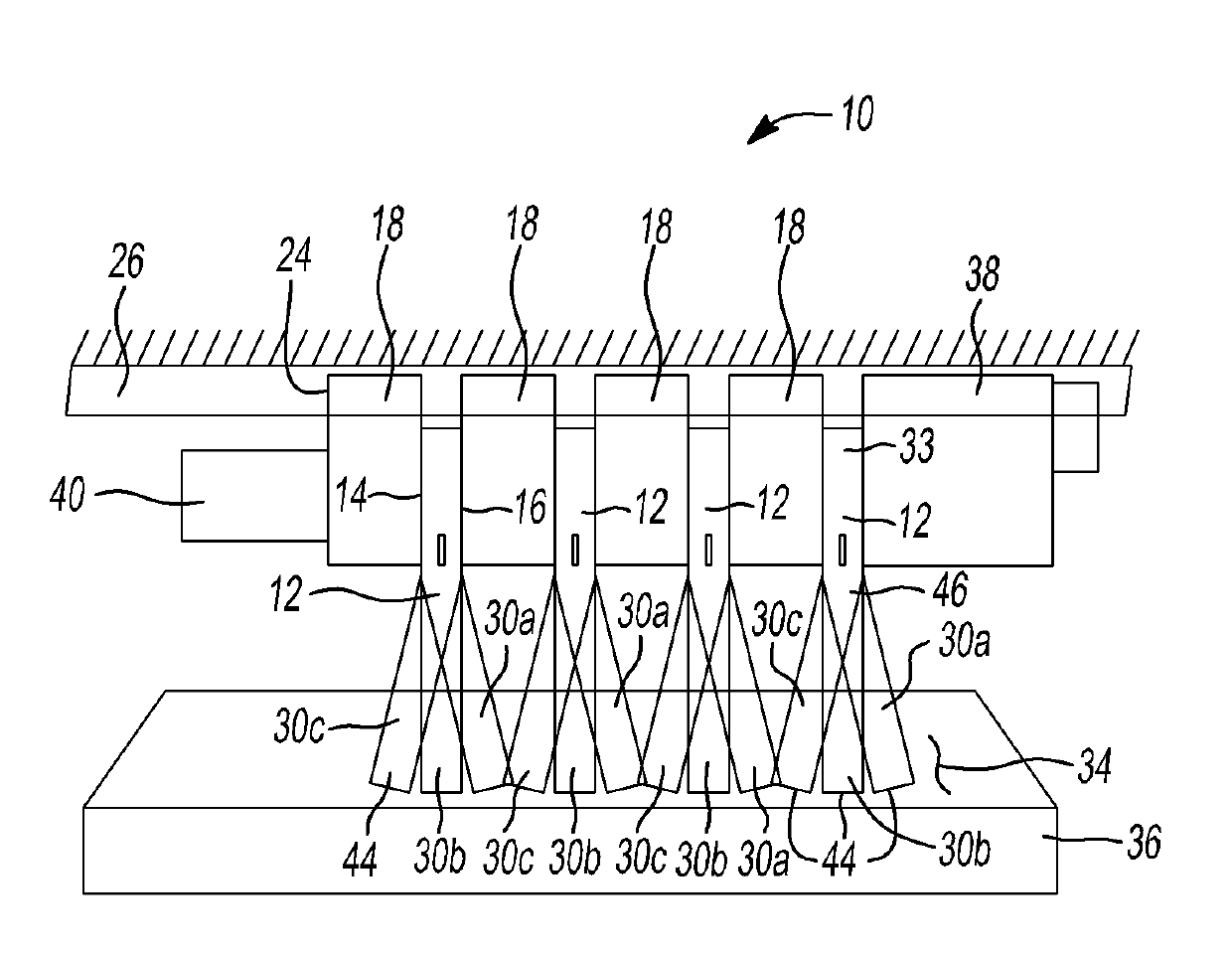

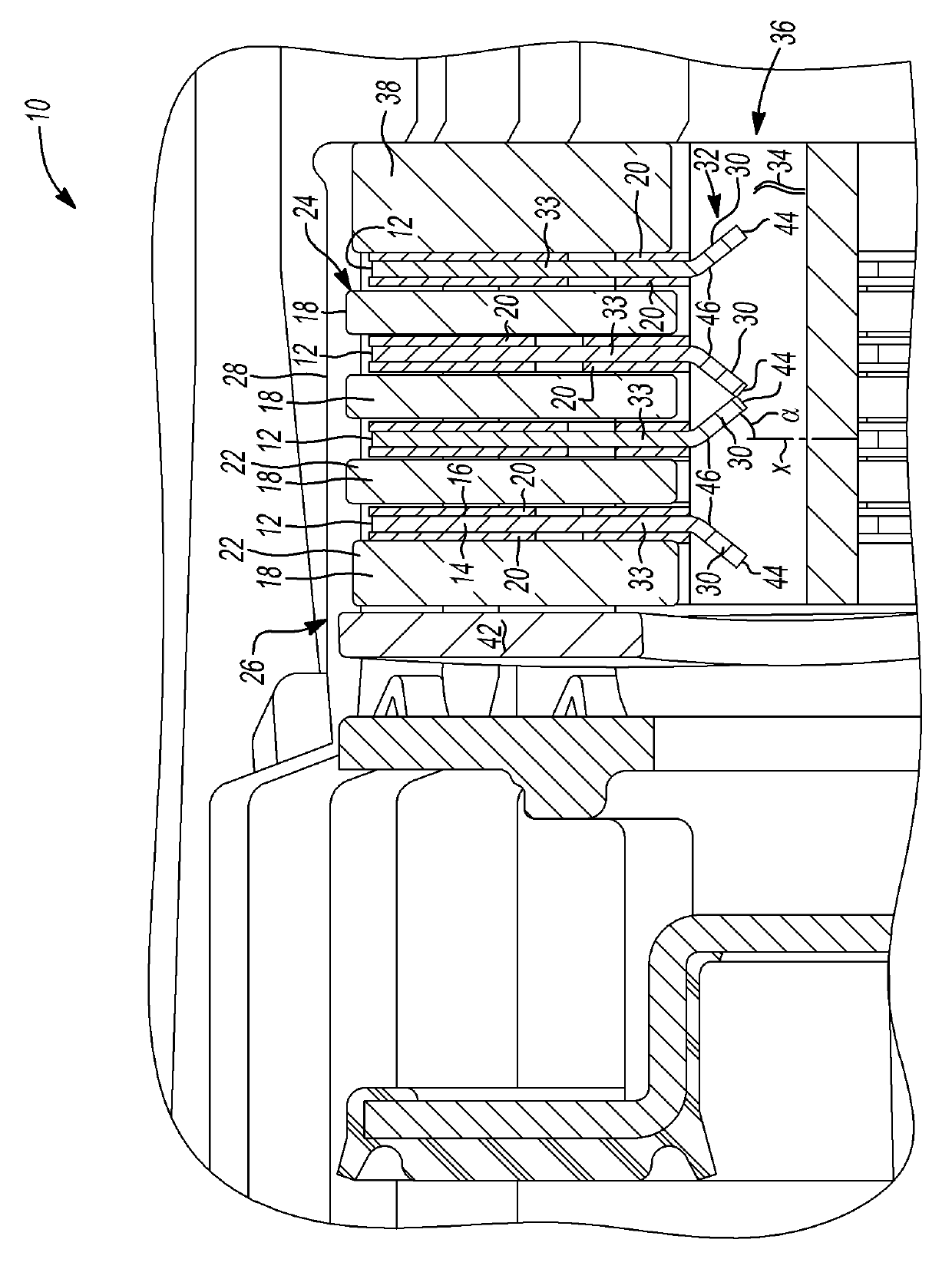

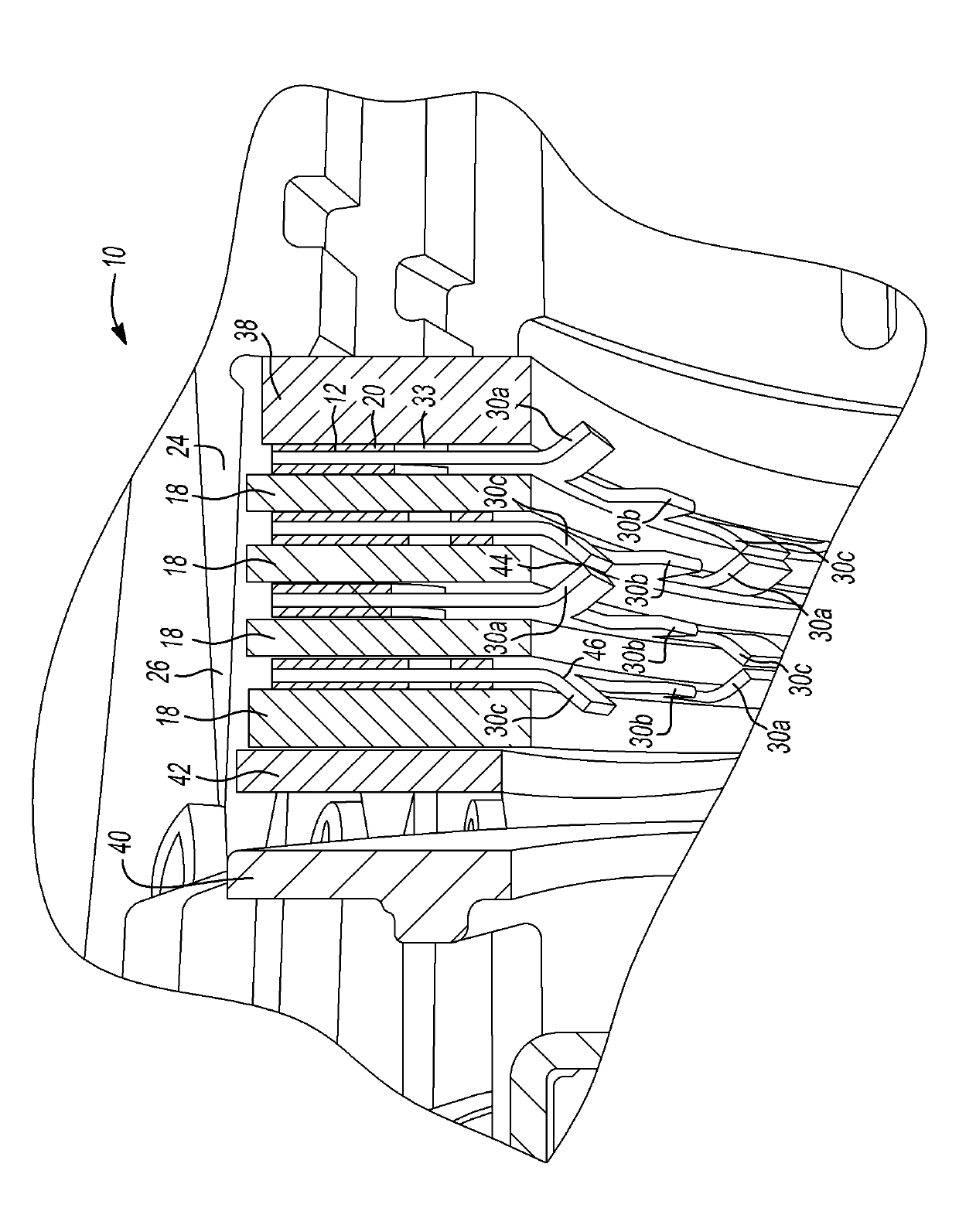

[0054] The present invention provides a multi-plate clutch assembly that reduces spin loss and drag within the plate clutches of the multi-plate clutch assembly by providing a separation force between the plates. Separation forces may additionally or alternatively be applied to the separator sheets. The separation force can be achieved by attaching a spring, such as a Belleville spring, to the chip (and / or separator sheet). The spring may be integrally formed with the chip (and / or separator sheet). For example, in one form the teeth of the blade are curved or formed at an acute angle relative to the plane of the blade. At least one tooth of a first piece contacts at least one tooth of a second adjacent piece when mounted, thereby providing a separation force between adjacent chips (and / or separator pieces).

[0055] see now Figure 1-4 , whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com