Member installation apparatus and member shape identification method

A technology for installing devices and components, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of increased production takt time, time spent, and production takt loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Hereinafter, a component mounting device according to an embodiment of the present invention will be specifically described with reference to the drawings.

[0062] In addition, the embodiment described below shows a specific example of the present invention. Numerical values, shapes, materials, constituent elements, arrangement positions and connection forms of constituent elements, steps, order of steps, etc. shown in the following embodiments are examples, and are not intended to limit the present invention. In addition, among the constituent elements of the following embodiments, constituent elements not described in the independent claims representing the highest concept will be described as arbitrary constituent elements.

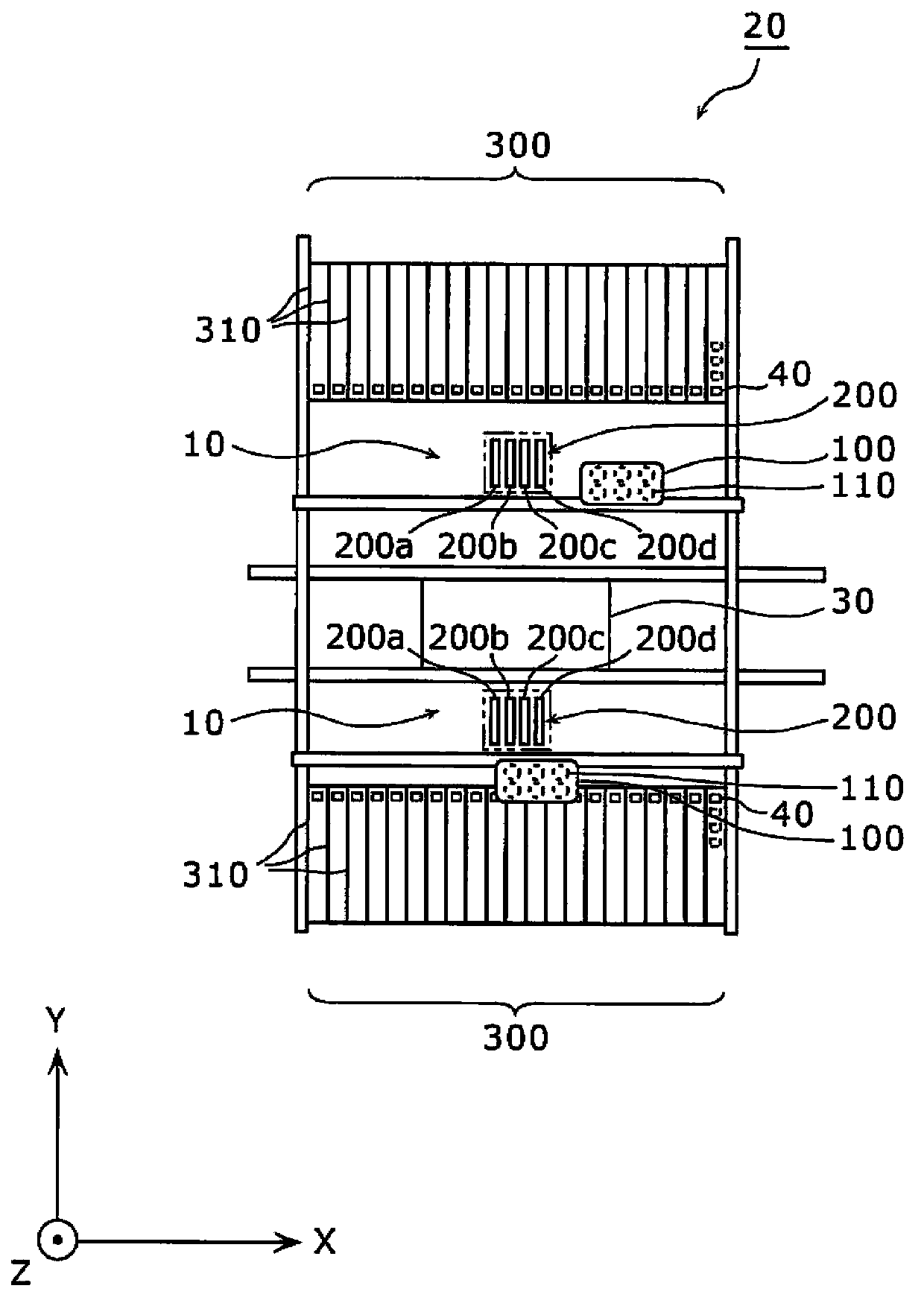

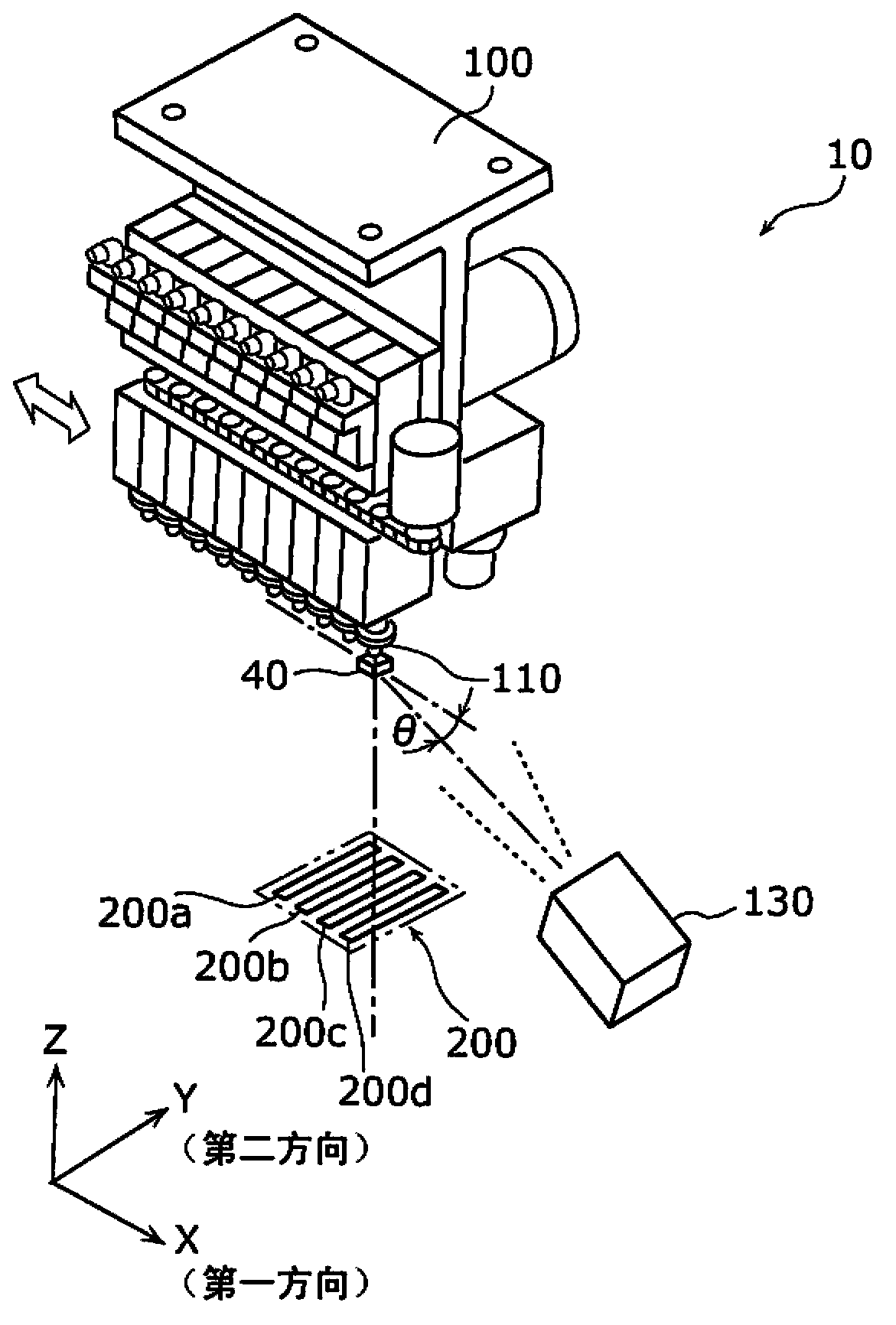

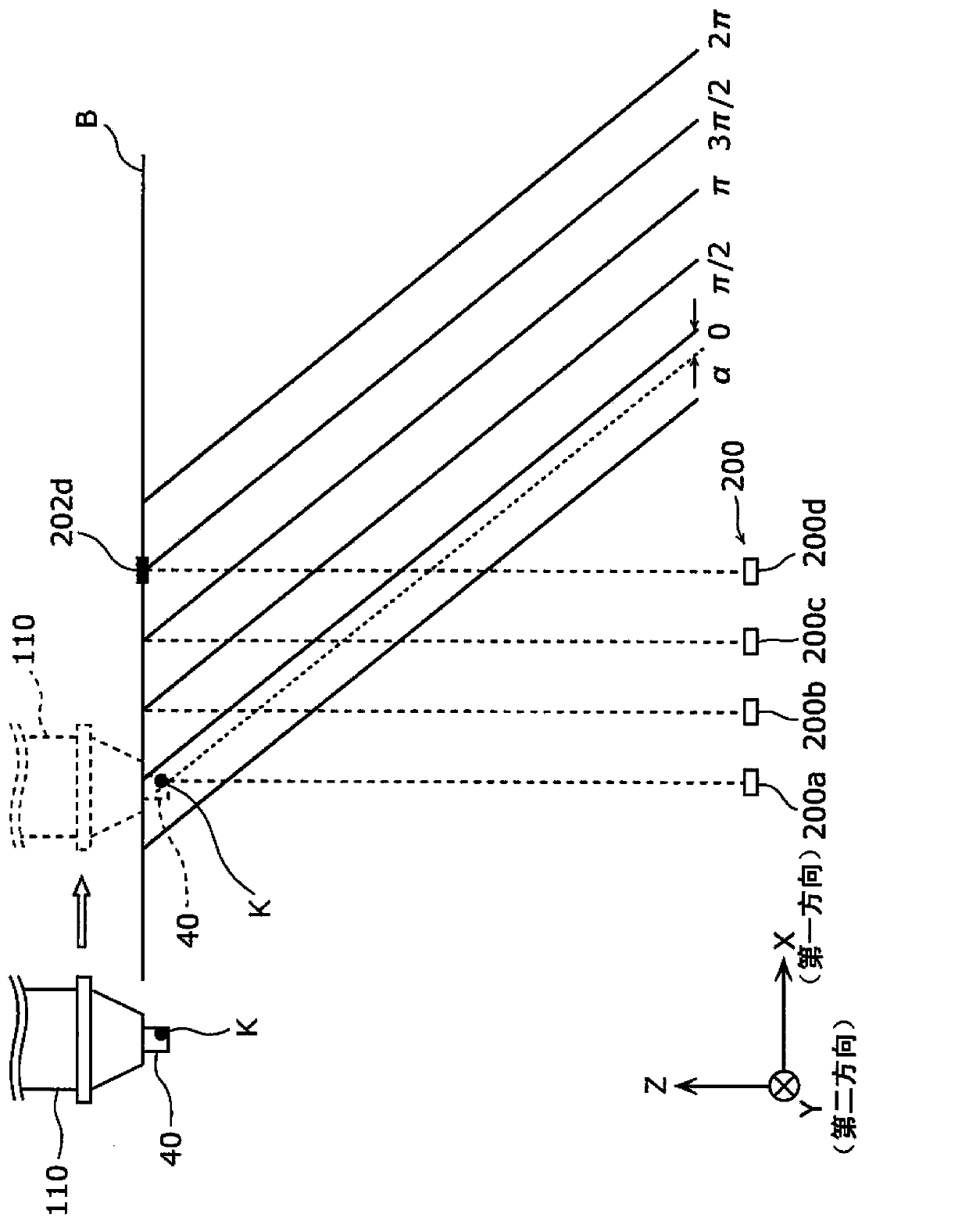

[0063] figure 1 It is a plan view showing the internal main configuration of the component mounting device according to the present embodiment.

[0064] The component mounting device 20 is a device for mounting the component 40 on the substra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap