Edge-infolding bearded needle rotating mechanism driven by servomotor

A servo motor and rotating mechanism technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of difficult to control the gap of the motion pair, large influence on the rotation accuracy of the crochet needle, and large error magnification. Good high-speed adaptability and small error magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

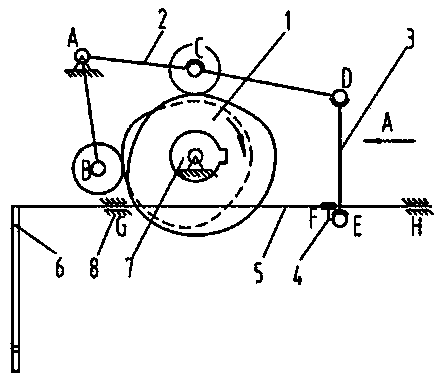

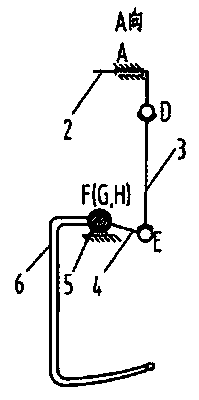

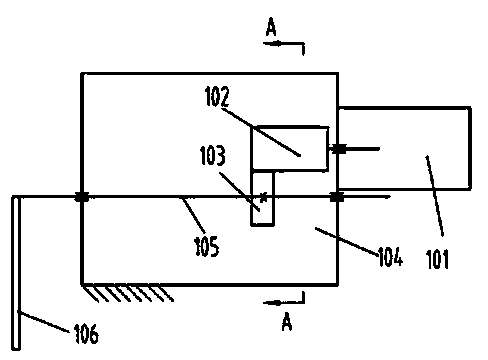

[0014] The present invention will be described in detail below in conjunction with accompanying drawing: image 3 , 4 As shown, a turning mechanism of crochet hooks driven by a servo motor, which includes a box body 104, on which a servo motor 101 is fixedly installed, and the output shaft of the servo motor 101 passes at least through a pair of gear transmission pairs Connect with a crochet telescopic shaft 105, the crochet telescopic shaft 105 is hinged on the box body 104 through a bearing, one end of the crochet telescopic shaft 105 is fixedly connected with a crochet needle 106, the middle part of the crochet telescopic shaft 105 is axially connected with the crochet telescopic shaft 105 The moving cam mechanism is connected.

[0015] As shown in the figure, the output shaft of the servo motor 101 is fixedly connected with a transmission gear 102, and the crochet telescopic shaft 105 meshes with the transmission gear 102 through the fixed gear 103 on it, and the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com