Nameplate adsorbing device

A technology of adsorption device and nameplate, applied in the direction of workpiece clamping device, manufacturing tools, etc., can solve the problems of incomplete processing, difficult processing, and inability to fix the nameplate on the worktable, etc., and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

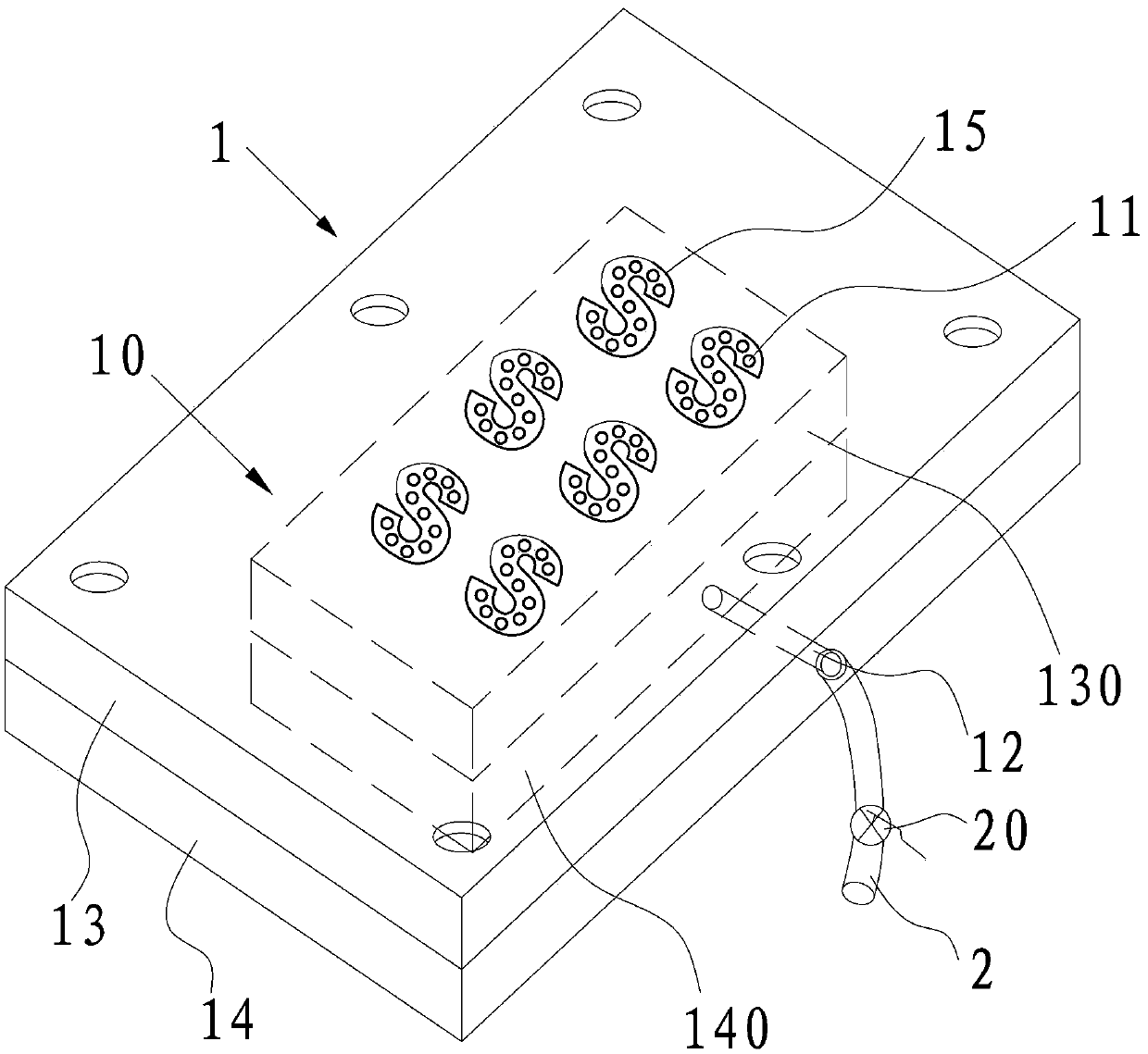

[0014] Such as figure 1 As shown, the nameplate adsorption device provided in this embodiment includes a tool box body 1 with a cavity 10 inside, and a vacuum system (not shown in the figure) for evacuating the inner cavity 10 of the tool box body 1 . , the upper surface of the tool box body 1 has a plurality of adsorption holes 11 that communicate with the cavity 10, and the tool box body 1 is also provided with a vent nozzle 12 that communicates with the cavity 10, and the air pipe 2 of the vacuum system is connected to the vent hole The mouths 12 communicate with each other, and an air valve 20 is also provided on the trachea 2 .

[0015] The above-mentioned tool box body 1 includes two detachably connected upper box body 13 and lower box body 14, wherein the upper box body 13 is recessed from the lower end to form an upper groove 130, and the lower box body 14 is inwardly from the upper end The depression forms a lower groove 140 , and the upper groove 130 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com