Positional accuracy testing method of space manipulator in thermal vacuum tank

A space manipulator, precision testing technology, applied in the direction of measuring devices, electrical devices, instruments, etc., can solve the problem of low precision test of space manipulator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

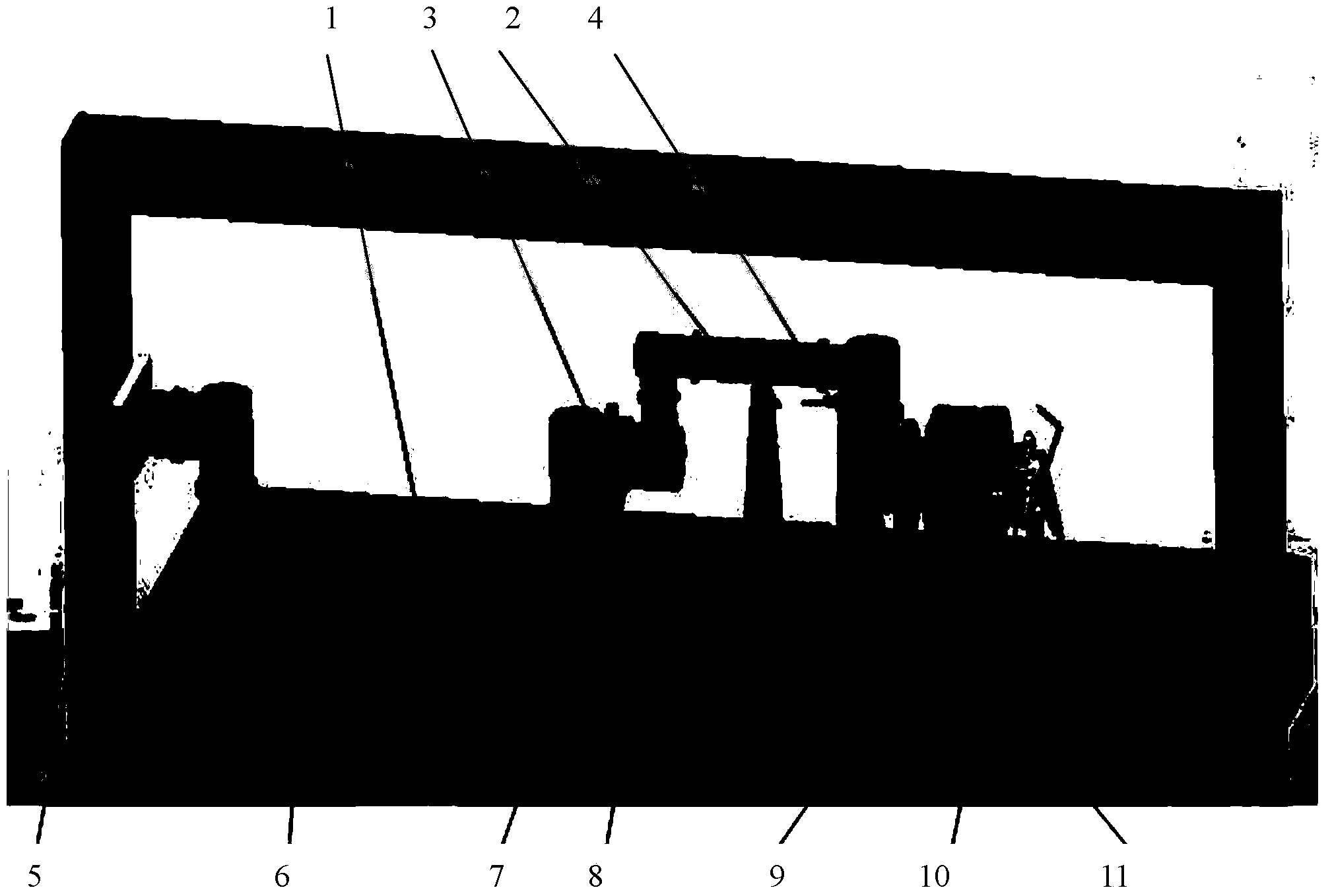

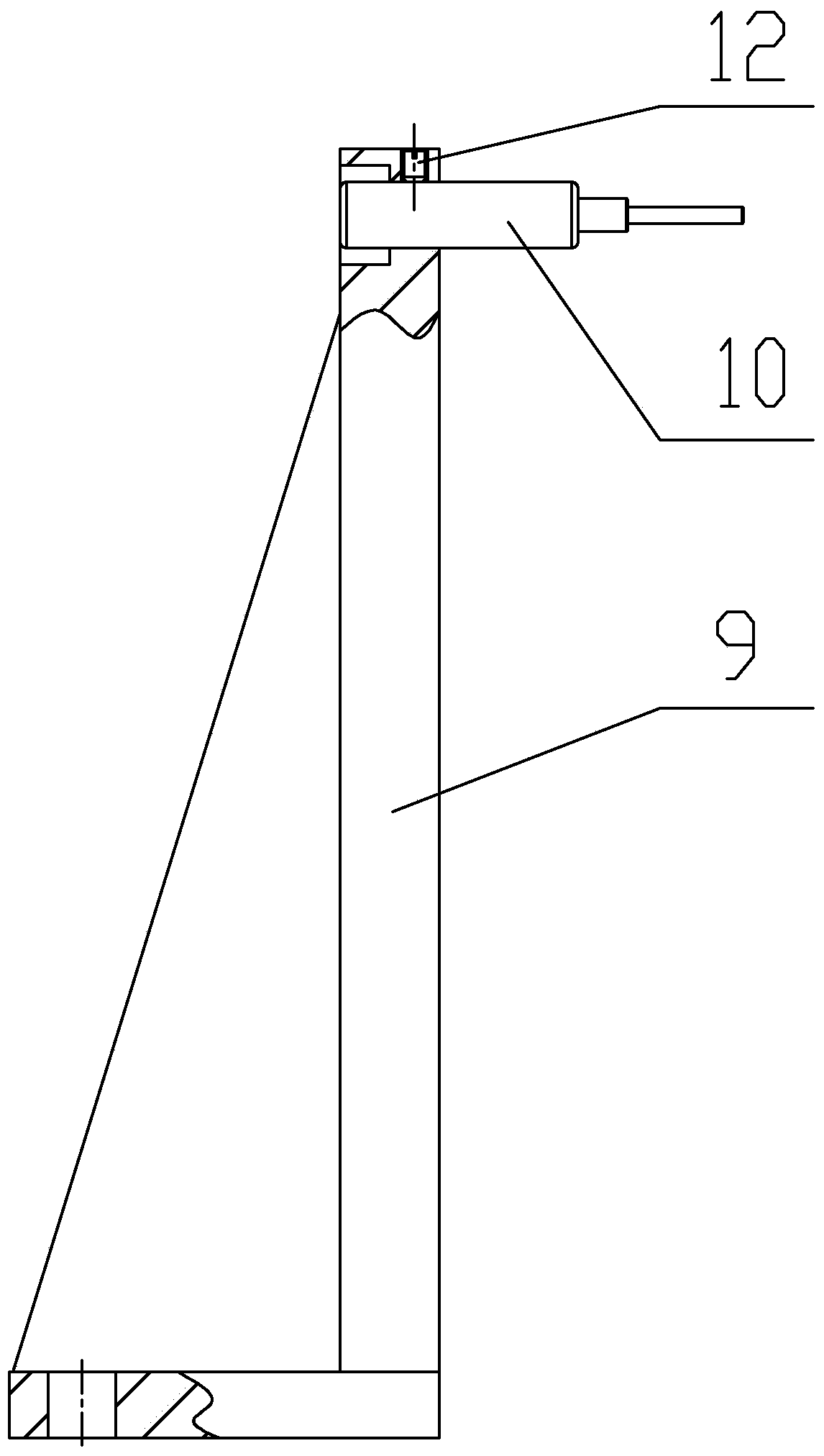

[0014] Specific implementation mode one: as Figures 1 to 3 As shown, a method for testing the position accuracy of a space manipulator in a thermal vacuum tank described in this embodiment is based on including a thermal vacuum tank and a mechanical arm mounting frame 5 located in the thermal vacuum tank, a steel plate 11, a roller 8, and a support frame 7 , guided rebound type LVDT displacement sensor 10 and the test system of the sensor fixing frame 9, the mechanical arm mounting frame 5 is fixedly connected to the steel plate 11, and the space manipulator 6 is placed on the steel plate 11 and is located in the mechanical arm mounting frame 5 , the base (root) flange of the space manipulator 6 is fixed on the inner wall of the corresponding side column of the manipulator mounting frame 5, and the space manipulator 6 is composed of the first arm 1, the first arm connected in sequence from the base end to the end The joint 3, the second arm bar 2 and the second joint 4 are fo...

specific Embodiment approach 2

[0019] Specific embodiment two: The LVDT displacement sensor 10 described in this embodiment is a guided rebound type LVDT displacement sensor with a relative accuracy of 0.05%, a resolution of 0.001 μm, an elastic force of less than 0.2N, and a temperature adaptable range of -40°C to 150°C. ℃. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: as Figures 1 to 3 As shown, the guided springback LVDT displacement sensor described in this embodiment has a relative accuracy of 0.05%, a resolution of 0.001 μm, an elastic force of less than 0.2N, and a temperature adaptable range of -40°C to 150°C. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com