Commodity driving structure

A technology for driving structures and goods, applied in the direction of coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., which can solve problems such as inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

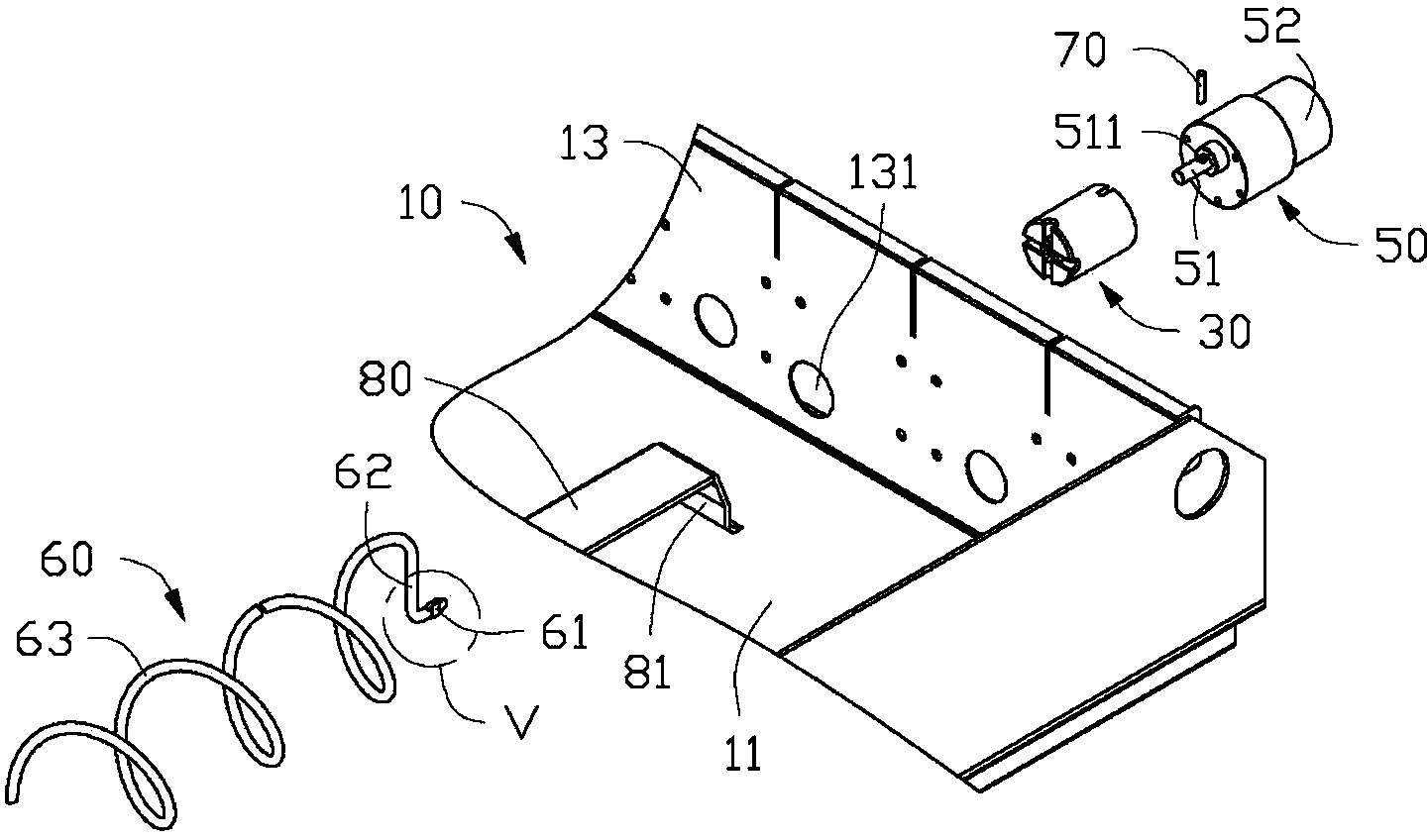

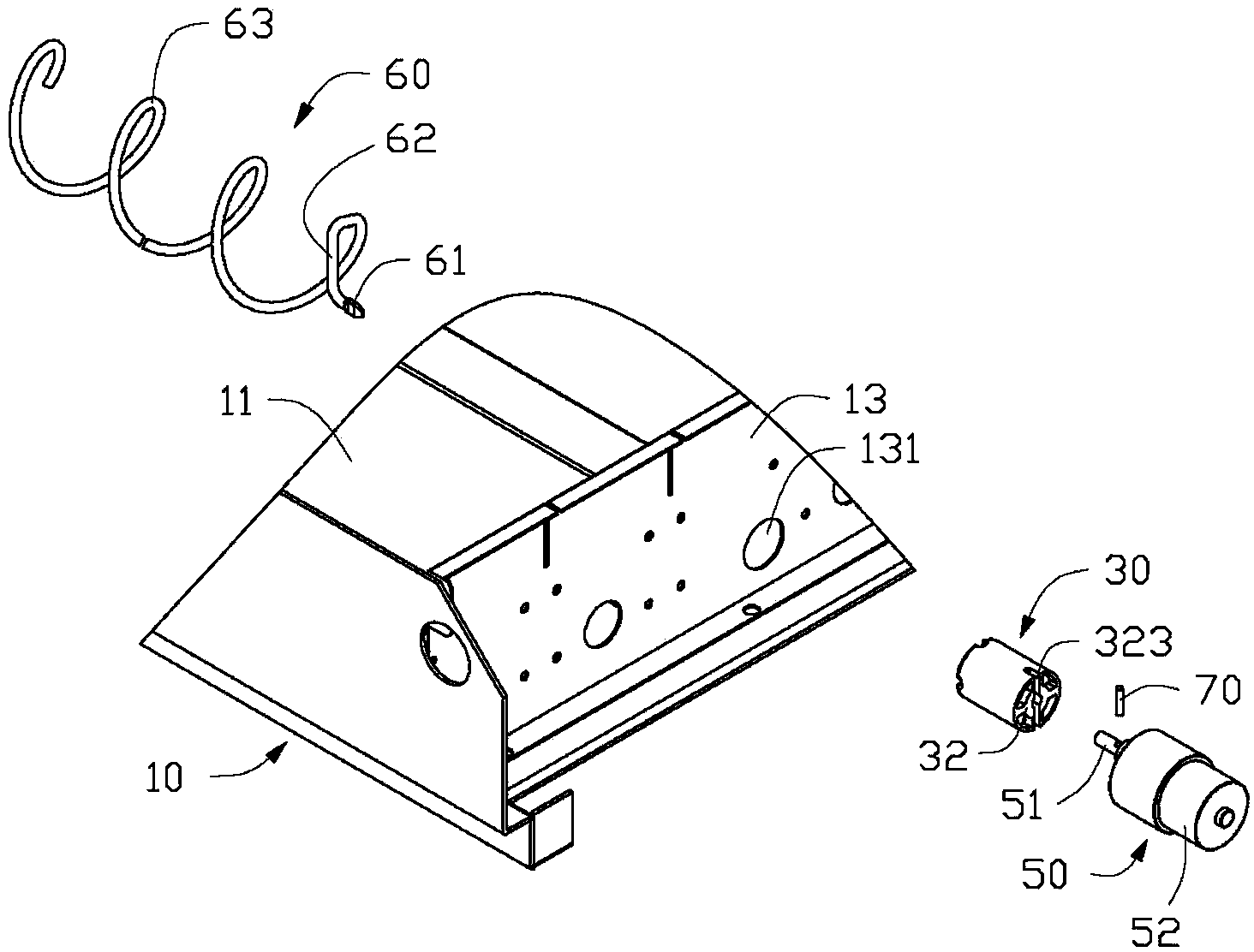

[0024] See figure 1 and figure 2 In a preferred embodiment of the present invention, a cargo driving structure includes a base 10, a fixing member 30, a driving member 50, and a pushing member 60. The cargo driving structure can push the cargo placed on the pushing member 60 out of the base 10 by rotating the pushing member 60.

[0025] The base 10 includes a bottom plate 11 and a side plate 13 perpendicular to the bottom plate 11. A supporting sheet 80 is installed on the bottom plate 11. The supporting sheet 80 is a long sheet body, and the supporting sheet 80 includes two fixed ends 81 (only one fixed end 81 is shown in the figure). The fixed end 81 is fixed on the bottom plate 11. The side plate 13 is provided with a receiving hole 131 for placing the driving member 50. In one embodiment, the stand 10 is a container on a vending machine.

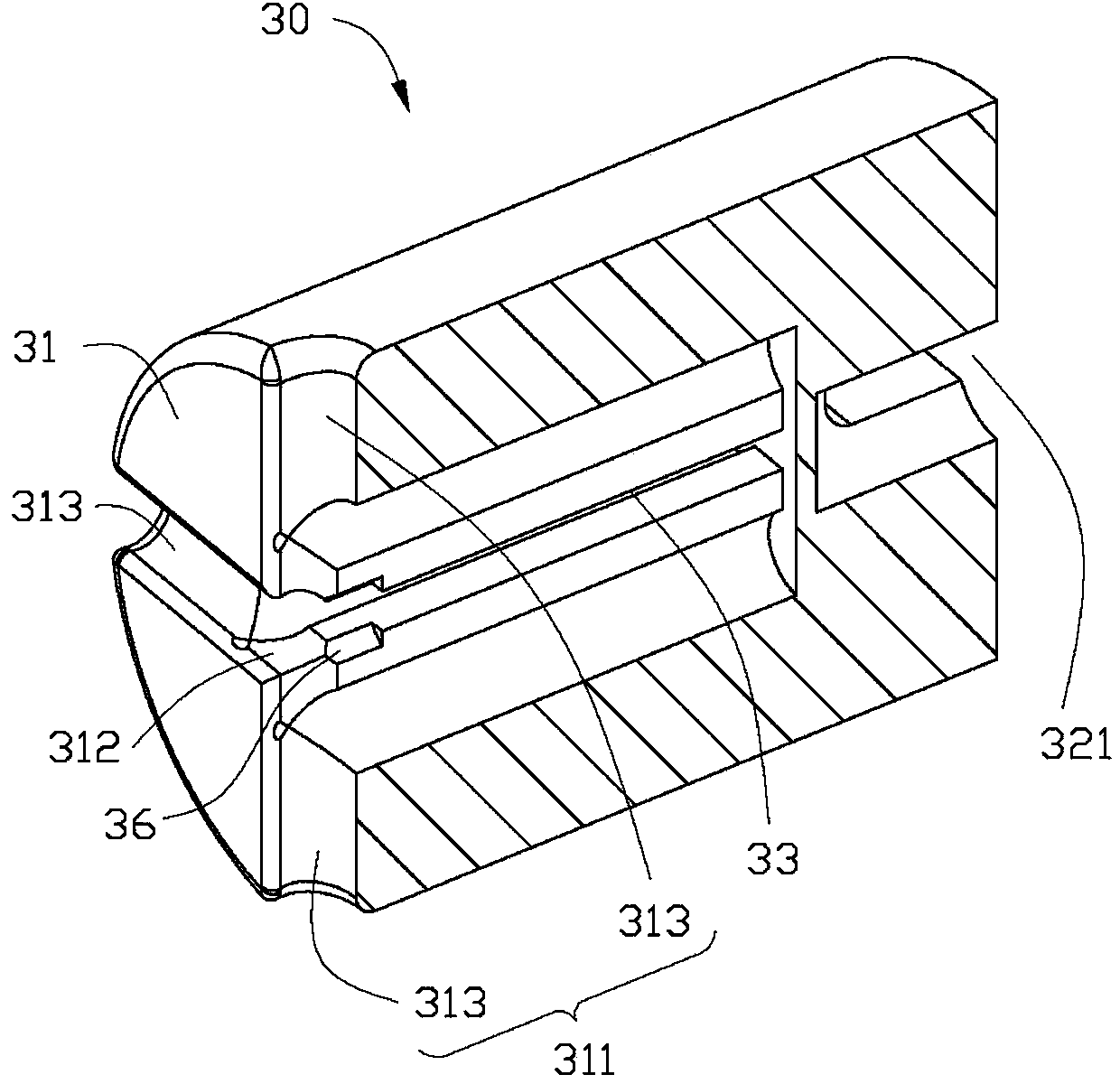

[0026] Please refer to image 3 and Figure 4 The fixing member 30 is a cylinder and includes a first side surface 31 and a second side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com