Valve clack assembling and fixing device for three-eccentric center butterfly valve production and machining

A technology for triple eccentric butterfly valves and fixing devices, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve the problems of affecting the production and assembly efficiency of triple eccentric butterfly valves, affecting the efficiency of valve clack assembly, and inconvenient valve clack fixing, etc., to achieve practical Good effect, increase production efficiency, easy to assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

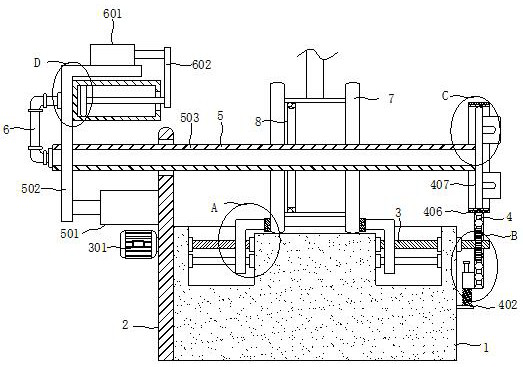

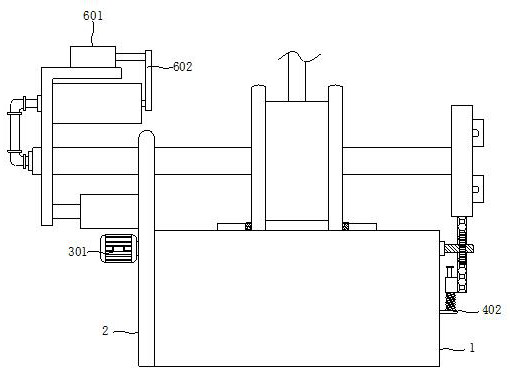

[0026] see Figure 1-6 , the present invention provides a technical solution: a disc assembly and fixing device for triple eccentric butterfly valve production and processing, including an assembly table 1, a vertical plate 2 is fixedly installed on one side of the assembly table 1, and a positioning Mechanism 3, one side of the assembly platform 1 is provided with a lifting mechanism 4, the other side of the assembly platform 1 is provided with a moving mechanism 5 and a fixing mechanism 6, and a flange 7 is provided above the assembly platform 1, and the inside of the flange 7 A valve seat 8 is provided.

Embodiment 2

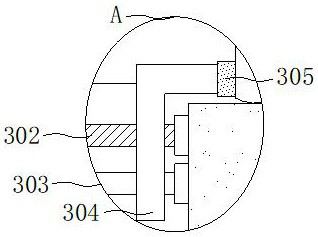

[0028] see Figure 1-6 , on the basis of Embodiment 1, the positioning mechanism 3 includes a motor 301, a two-way threaded rod 302, a sliding rod 303, a right-angle positioning block 304 and an anti-slip sponge 305, and the motor 301 is fixedly installed on the outer wall of one side of the vertical plate 2, and the assembly table 1 There is a movable groove at the top of the top, the two-way threaded rod 302 is rotatably installed inside the movable groove, the output shaft of the motor 301 extends to the inside of the movable groove through a coupling and is fixedly connected with the two-way threaded rod 302, and the sliding rod 303 is fixedly installed on the movable groove. Inside the groove, two groups of right-angle positioning blocks 304 are arranged on the two-way threaded rod 302 and the slide bar 303. Adjacent side walls are fixedly equipped with non-slip sponges 305. During assembly, the flange 7 is first placed on the top of the assembly table 1, and then the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com