High-pressure tee rotary valve

A technology of three-way and rotary valves, applied in the direction of multi-way valves, valve devices, engine components, etc., can solve the problems of poor sealing effect of rotary valves, material leakage, inaccurate flow adjustment, etc., and achieve good sealing effect and accurate flow adjustment , Reasonable and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below through specific embodiments. It should be pointed out that for those of ordinary skill in the art, without departing from the principle of the present invention, some modifications and improvements can also be made, and these should also be regarded as belonging to the present invention. protection scope of the invention.

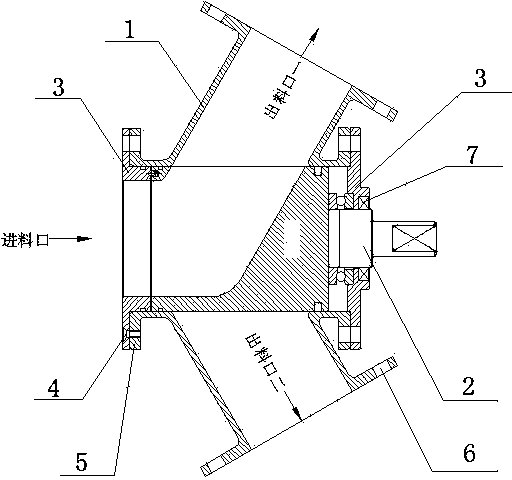

[0010] Such as figure 1 As shown, the high-pressure three-way rotary valve includes a valve body 1 with a feed port and two discharge ports, a valve core 2 is provided between the two discharge ports, and a control valve is provided on the valve core 2. The wrench for the core 2; the end cover 3 is provided at the inlet, the outlet and the valve core 2, the end cover 3 is connected with the valve body 1 through the cross countersunk head screw 4, and the end cover 3 is also equipped with thrust bearing 5 and gray ring 6; a skeleton oil seal 7 is also provided between the valve core 2 and the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com