Ruthenium purifying technology in plutonium purification cycle of Purex process

A purification process and plutonium purification technology are applied in the purification process field of ruthenium in the plutonium purification cycle of the Purex process to achieve the effects of improving purity, high plutonium yield and reducing ruthenium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

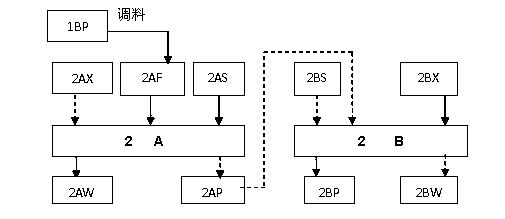

[0014] Under the condition of temperature of 20℃, add extractant 2AX and detergent 2AS in tank 2A to remove a small amount of fission elements such as uranium and ruthenium in the 2AF feed liquid. The key is that the extractant 2AX used is 30% TBP / kerosene, Detergent 2AS is c(HNO 3 )=0.5mol / L aqueous solution, the flow ratio is 2AF:2AX:2AS=3.5:1:0.45, and the composition of the 2AF feed solution used is: c(Pu 4+ )=6.8g / L, c(UO 2 2+ )=0.74g / L, c(HNO 3 )=3.5mol / L, c(Ru)=0.3108mg / L aqueous solution, the selected extraction stage is 8, the washing stage is 6, and the ratio of organic phase to water phase is 2:1.

[0015] During the experiment, the tank was filled with the feed solution without uranium and plutonium for two hours, and then the feed solution containing uranium and plutonium was added. After running for 5.0 hours, samples were taken every 2 hours. After running for 16 hours, the bath was stopped for analysis. .

[0016] Experimental results: the yield of urani...

Embodiment 2

[0018] The steps used in Example 1 are the same, except that the detergent 2AS is c(HNO 3 )=1mol / L aqueous solution, the selected flow ratio is 2AF:2AX:2AS=5:1:0.45, and the composition of 2AF is c(Pu 4+ )=2.75g / L, c(UO 2 2+ )=1.2g / L, c(HNO 3 )=3.5mol / L, c(Ru)=0.054mg / L aqueous solution, the number of extraction stages is 9, the number of washing stages is 8, and the temperature is 30°C. The obtained experimental results are: the yield of plutonium is 99.97%, Purification factor DF of Ru Ru =3590.

Embodiment 3

[0020] The steps used in Example 1 are the same, except that the detergent 2AS is c(HNO 3 )=1.5mol / L aqueous solution, the selected flow ratio is 2AF:2AX:2AS=6:1:0.45, and the composition of 2AF is c(Pu 4+ )=2.75g / L, c(UO 2 2+ )=1.2g / L, c(HNO 3 )=3.5mol / L, c(Ru)=0.054mg / L aqueous solution, the number of extraction stages is 10, the number of washing stages is 10, and the temperature is 30°C. The obtained experimental results are: the yield of plutonium is 99.98%, Purification factor DF of Ru Ru =3120.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com