Double-centralization wellhead pipe fitting device

It is a double-fitting technology, which is applied in the direction of drill pipe, casing, drilling equipment, etc. It can solve the problems of low righting efficiency, time-consuming and laborious, and the failure of righting to quickly achieve the expected effect, and achieve the effect of high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

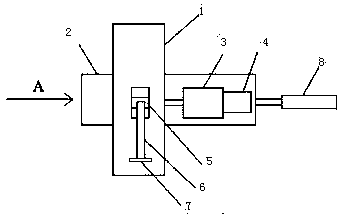

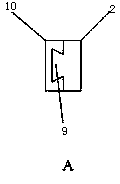

[0021] see figure 1 and figure 2 , the present invention is further described in detail: the main mounting plate 1 and the motor 4 are vertically fixed on the secondary mounting plate 2, the main mounting plate 1 is located at the parallel position on the left side of the motor 4; the main mounting plate 1 is provided with a rotating shaft 6, and the rotating shaft 6 is fixed One end of the centralizing arm 7, and the other end of the centralizing arm 7 is connected with the centralizing ring 8; the motor 4 is connected with the rotating shaft 6, drives the centralizing arm 7 to rotate, and straightens the pipe in a direction perpendicular to the paper surface; the right side of the auxiliary mounting plate 2 A slide plate 9 is provided, and the slide plate 9 is slidably arranged in the chute of the fixed plate 10, and the two ends of the chute are closed; When the auxiliary mounting plate 2 moves horizontally, the main mounting plate 1 moves horizontally with the auxiliary ...

Embodiment 2

[0023] see figure 1 and figure 2 , the present invention is further described in detail: the main mounting plate 1, the gearbox 3 and the motor 4 are vertically fixed on the secondary mounting plate 2, and the main mounting plate 1, the gearbox 3 and the motor 4 are sequentially fixed on the secondary mounting plate 2 in parallel; Installing plate 1 is provided with rotating shaft 6, and rotating shaft 6 fixes one end of righting arm 7, and the other end of righting arm 7 is connected with centering ring 8; 3 is connected, the motor 4 drives the centering arm 7 to rotate, the rotation speed of the centering arm 7 is adjusted through the gearbox 3, and the pipe fittings are righted in a direction perpendicular to the paper surface; In the chute of the fixed plate 10, both ends of the chute are closed; the telescopic end of the power expansion device 5 passes through the closed end of the chute and is connected with the slide plate 9. When the power expansion device 5 pushes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com