Electric pole automatic upright detecting and righting all-in-one machine for electricity rush repairing

A technology for emergency repair of electric power and utility poles, which is applied in the field of automatic straightening and straightening machine for utility poles for emergency repair of electric power, and can solve problems affecting the straightening work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

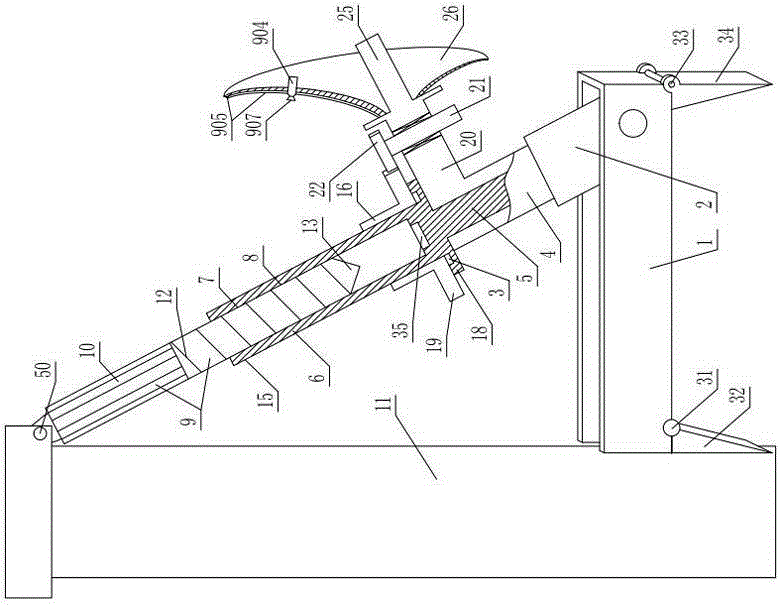

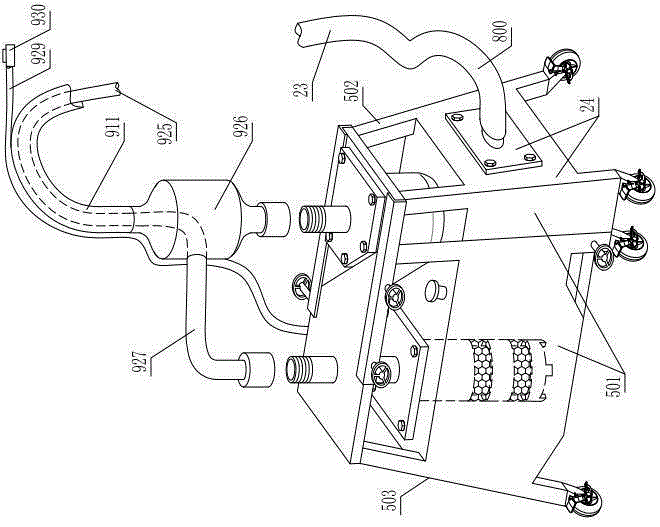

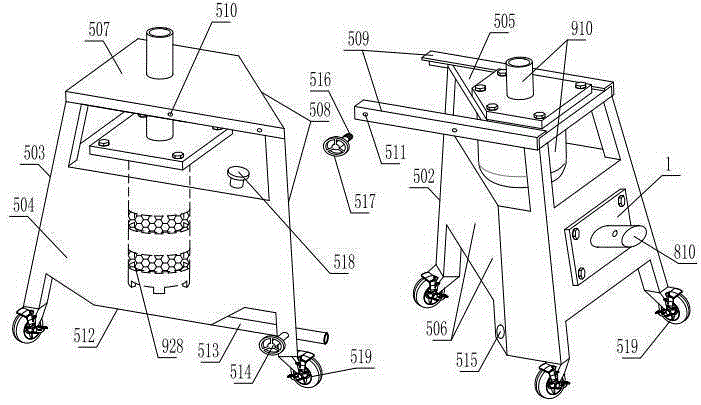

[0025] As shown in the figure, the utility pole automatic straightening and straightening all-in-one machine for emergency repair of electric power includes a base 1 arranged horizontally. The longitudinal section of the base is U-shaped. There is a front limit device extending downward. A swing tube 2 capable of swinging back and forth is hinged in the support section of the base, and a support sleeve 4 is inserted into the swing tube. An inner rotating shaft 5 that can only rotate coaxially relative to the support sleeve is installed in the support sleeve. The upper end of the inner rotating shaft is coaxially fixed with an inner cylinder 6 extending out of the support sleeve. The inner cylinder inner wall is uniformly provided with an axially extending inner cylinder straight groove 7. Slot 8. It also includes a multi-purpose shaft 9 that is inserted and matched with the inner cylinder. The upper ring of the upper half of the peripheral wall of the multi-purpose shaft is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com