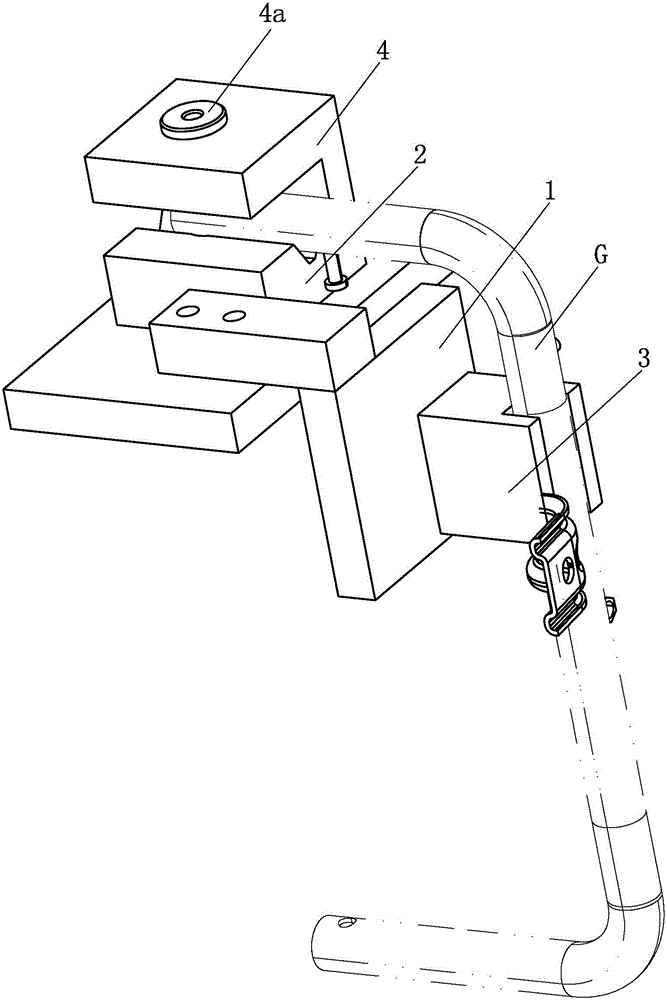

A U-shaped tube outrigger punching tool

A U-shaped tube and punching technology, which is applied in the field of fixtures and fixtures, can solve problems such as height differences, and achieve the effects of convenient use, high processing precision, good technical and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

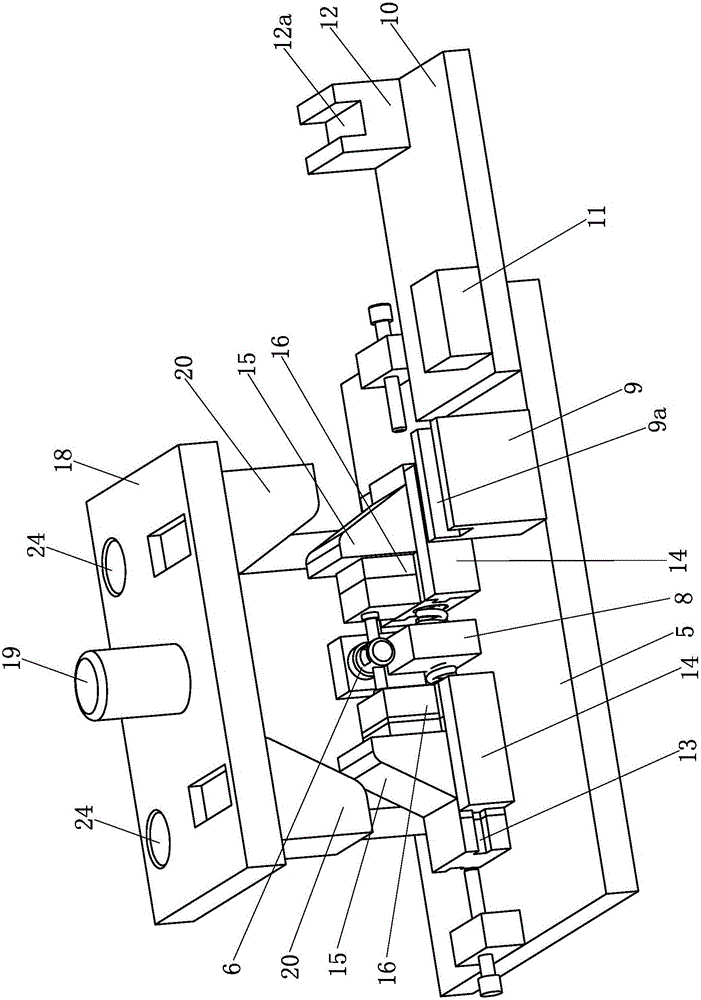

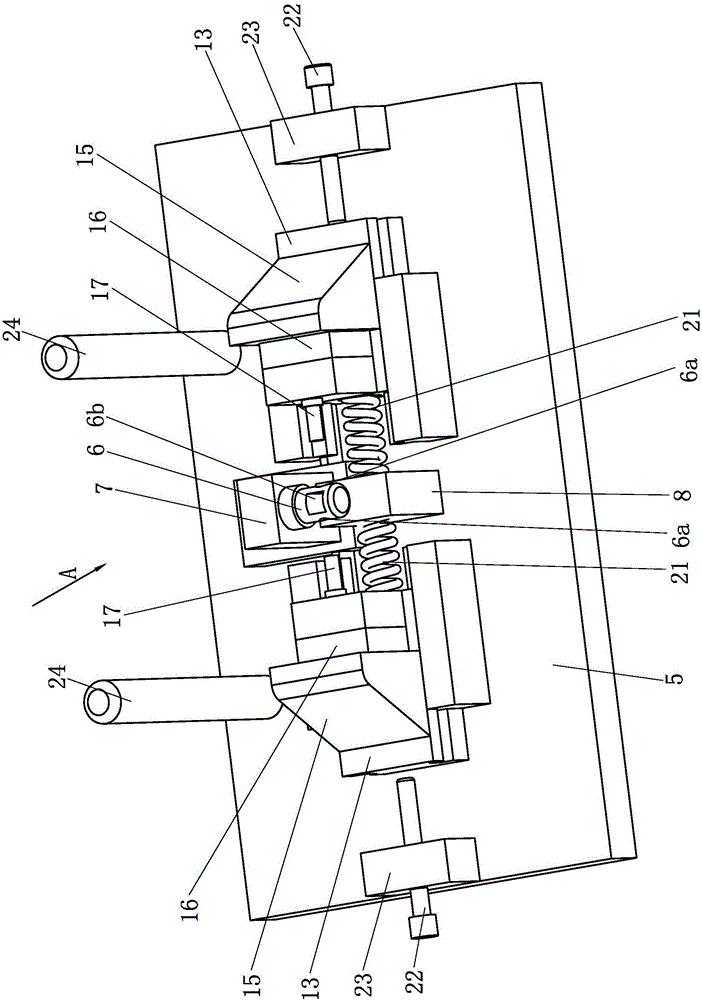

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0029] like figure 2 and 5As shown, a U-shaped tube leg punching tool is mainly composed of a horizontal base plate 5, a U-shaped tube positioning assembly, a side punching assembly, a die, a spring 21, a limit screw 22, a limit block 23, a guide column 24, an inlay Block 25 and adjusting screw 26 constitute. Wherein, a U-shaped tube positioning assembly and two side flush assemblies are provided on the top surface of the horizontal bottom plate 5, wherein the U-shaped tube positioning assembly mainly consists of a U-shaped tube positioning sleeve 6, a connecting block 7, and a first cushion block 8. , The first positioning block 9, the connecting plate 10, the second cushion block 11 and the second positioning block 12 constitute.

[0030] Wherein, the outer diameter of the U-shaped tube positioning sleeve 6 is adapted to the inner diameter of the U-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com