Core induction furnace melting power supply unit

A technology of power supply device and induction furnace, which is applied in the direction of circuit device, emergency power supply arrangement, induction heating, etc., can solve difficult power, adjustment and other problems, and achieve the effect of avoiding broken ditch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

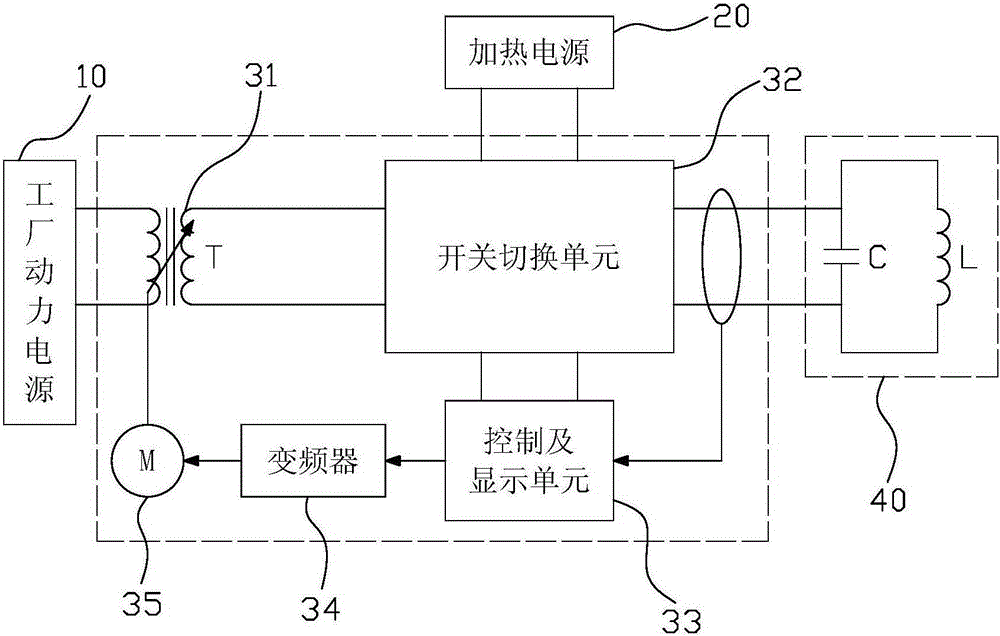

[0008] Combine below figure 1 , the present invention is described in further detail.

[0009] refer to figure 1 , a core induction furnace melting power supply device, the device includes an induction voltage regulator 31, a switch unit 32, a control and display unit 33, a frequency converter 34 and a voltage regulation drive motor 35, an inductor of a core induction furnace 40 A compensation capacitor C is connected in parallel at both ends of the coil L, and the factory power supply 10 and the heating power supply 20 supply power to the inductor coil L through the switching unit 32, wherein the factory power supply 10 passes through the induction voltage regulator 31, the switching unit 32 and the induction coil L is connected, and the heating power supply 20 is directly connected to the inductor coil L through the switching unit 32 . The switch switching unit 32 controls the on-off of the factory power supply 10 or the heating power supply 20 and the inductor coil L, tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com