Stay type automatic sowing machine

A seeder and wire-pulling technology, which is applied in the field of wire-pulling automatic seeders, can solve the problems of numerous equipment parts, complex structure, complicated operation procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

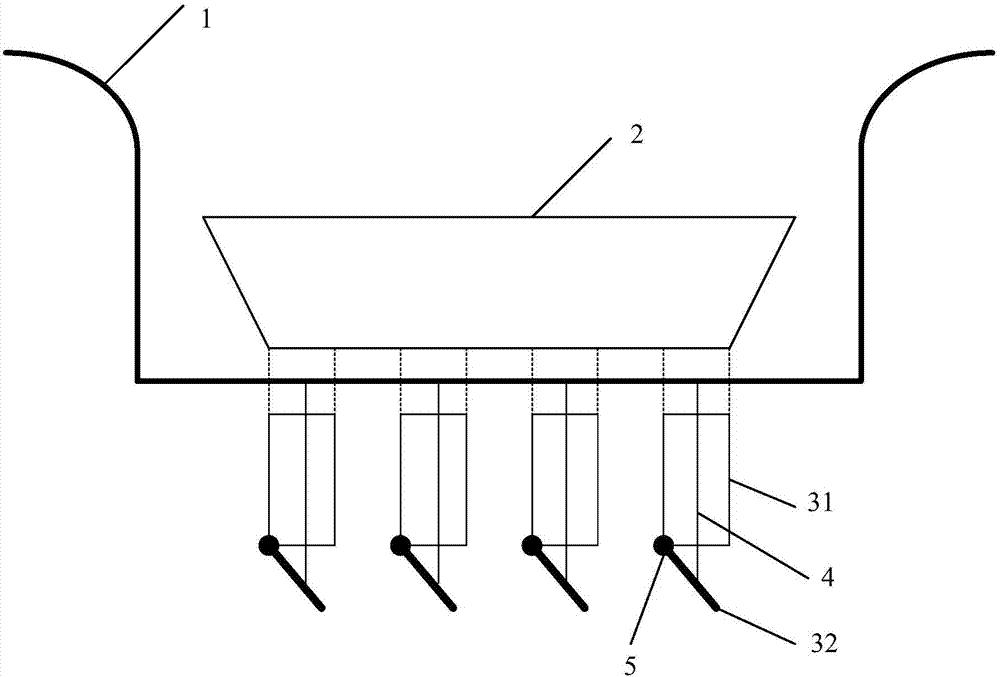

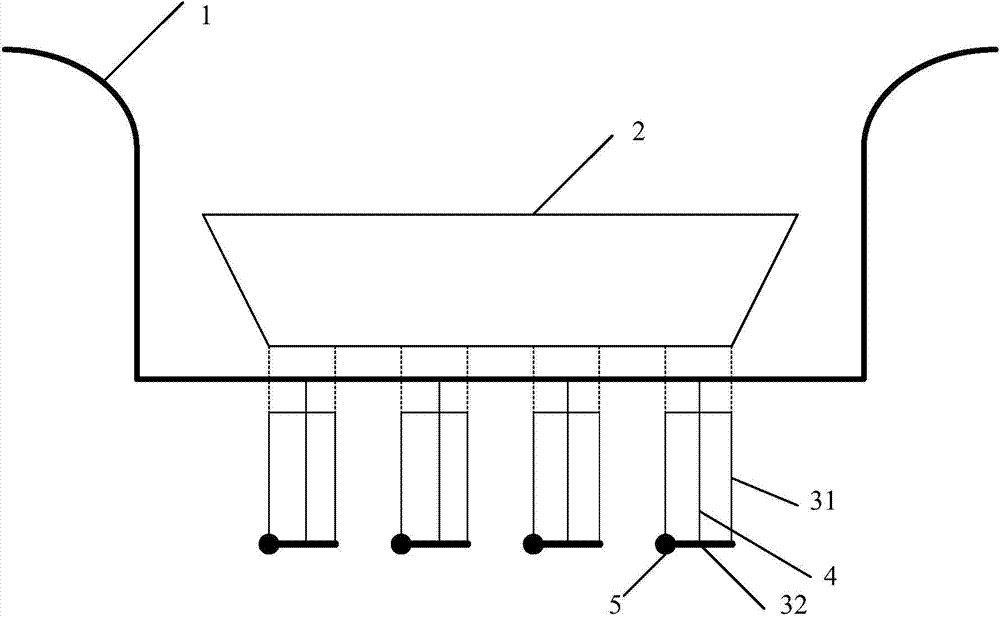

[0017] Embodiments of the present invention provide a wire-drawn automatic seeder, such as figure 1 and figure 2 As shown, it includes: a frame 1; a seed cup 2, which is arranged on the frame 1, and is used to hold seeds to be sown; a seed delivery tube, which is composed of a tube body 31 and a tube bottom 32, and the upper end of the tube body is connected to the tube bottom. Said seed cup 1 is connected, and is used for adding seeds to be sown; one end of the tube bottom 32 is pivotally connected to the corresponding edge of the bottom of the tube body 31 through the pin shaft 5, and in a natural state, the other end of the tube bottom 32 hangs down, so that the tube body 31 is in the Bottomless state: stay wire 4, one end of the stay wire 4 is connected to the end of the tube bottom away from the pin shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com