Grain seed direct sower

A technology for direct seeding and grain seeding, which is applied to agricultural machinery and implements, shovels, plows, etc., can solve the problems of unsatisfactory use effect, stuck in manual insertion, cumbersome planting operation, etc. Seed and sowing effect excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

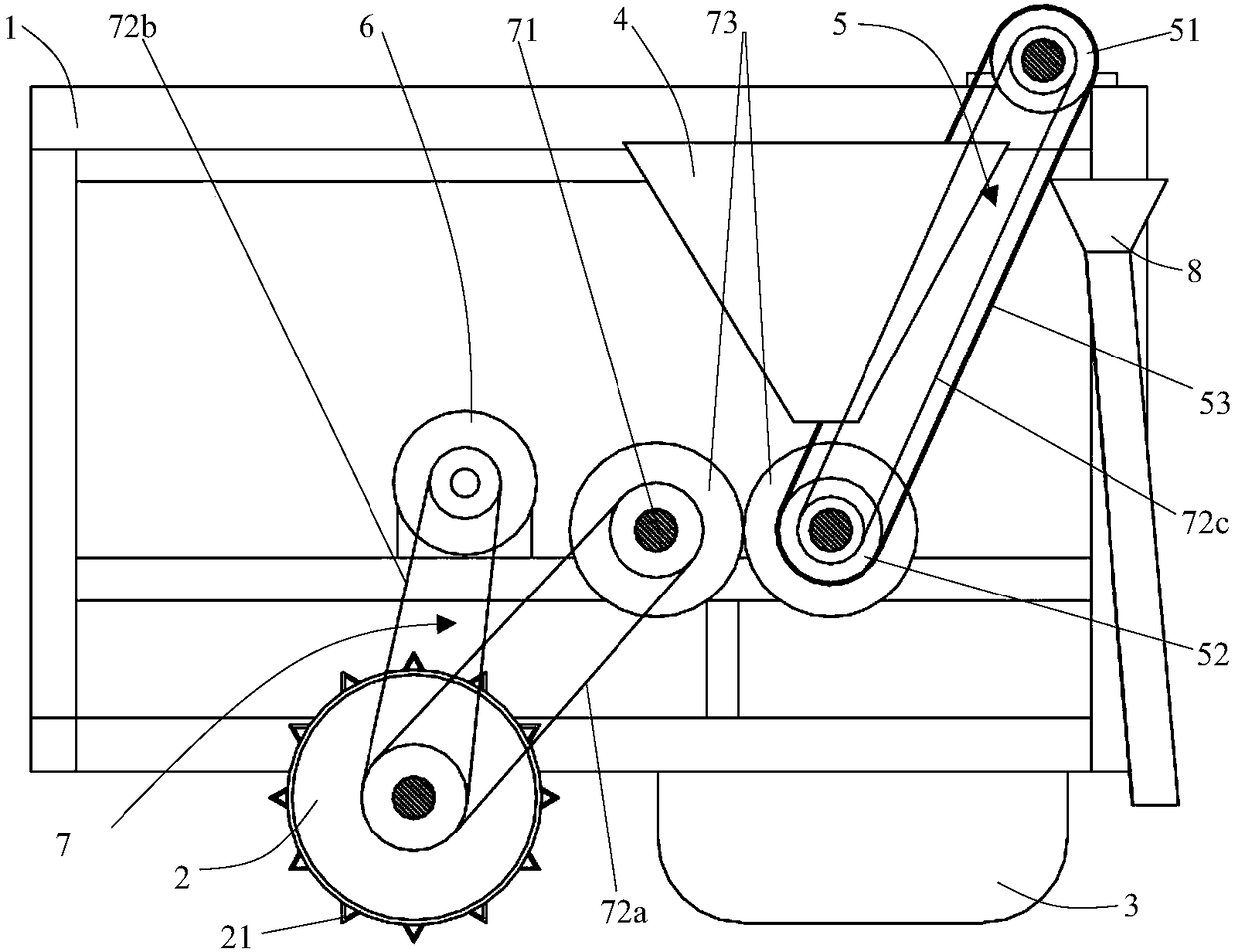

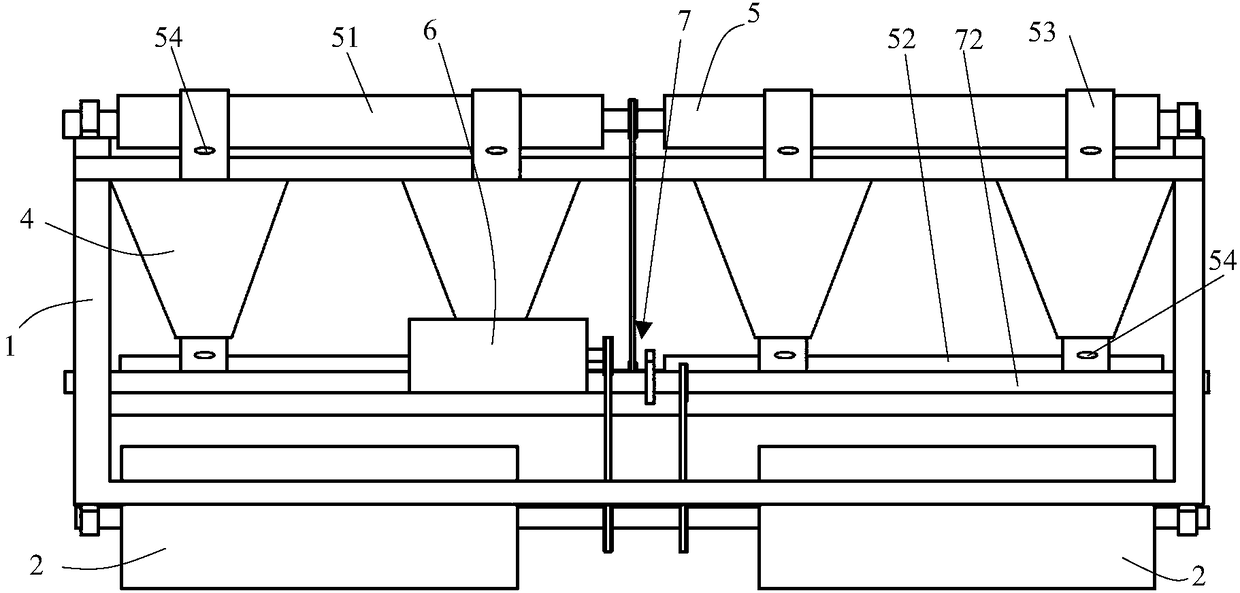

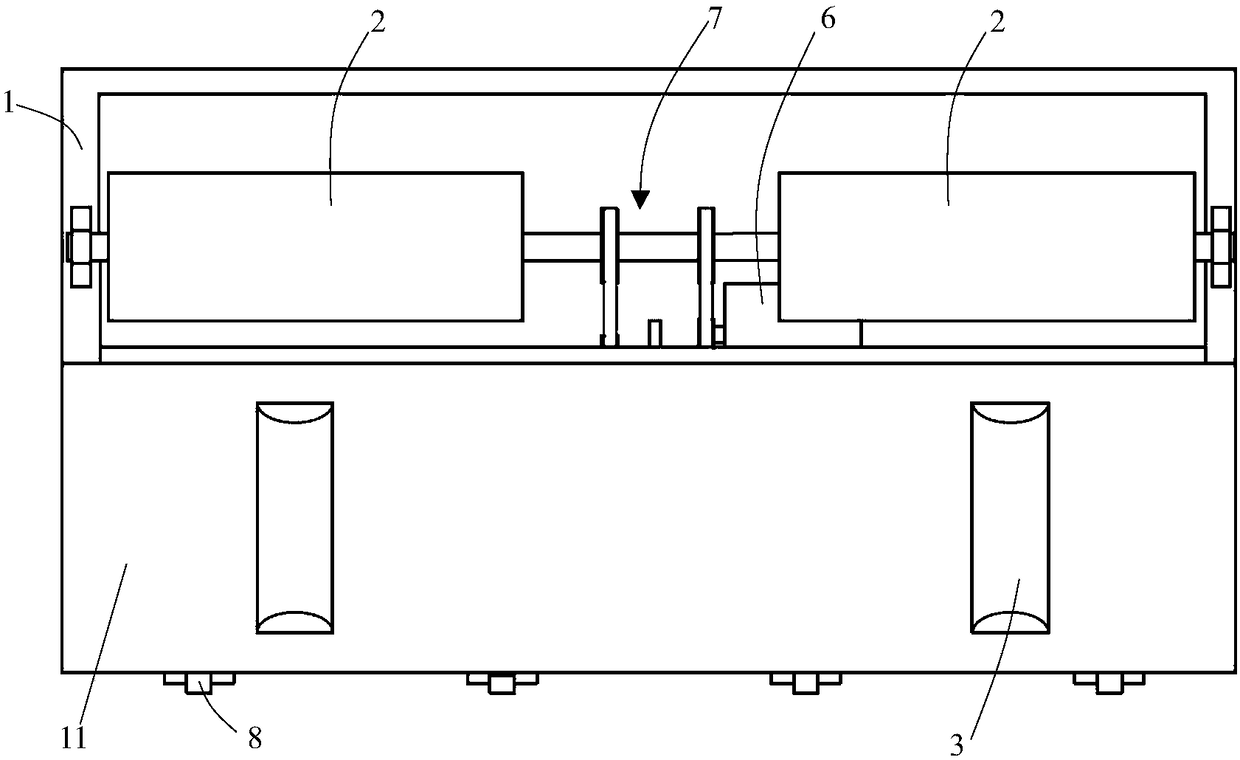

[0042] Such as Figure 1 to Figure 6 As shown, the direct seeding machine provided by this embodiment includes: a frame 1 and a roller 2, an opener 3, a seed funnel 4, a belt seeding device 5, a motor 6 and a roller set on the frame 1. Transmission mechanism 7.

[0043] The roller 2 protrudes downwards and is arranged at the front of the lower surface of the frame 1, and the surface of the roller 2 is provided with roller teeth 21 which are arranged along the axial direction of the roller 2 and are arranged on the circumference of the roller 2 There are multiple evenly arranged rollers. The roller 2 rotates forward, and the direct seeding machine is moved forward by the roller teeth 21. At the same time, the soil is simply plowed. At the same time, the whole long roller teeth avoids its entrapment. Grass and other foreign objects can be kept clean for a long time; the roller teeth 21 preferably use V-shaped teeth with the tip outwards, which can better ensure that they are not sl...

Embodiment 2

[0058] Such as Figure 7 to Figure 10 As shown, the components included in this embodiment, and the position and connection relationship between the components are basically the same as those in Embodiment 1, except that it also includes a fertilizing device 9. The fertilizing device 9 in this embodiment includes: Fertilizer funnel 91 and shaft tube 92.

[0059] See Figure 7 The fertilizer funnel 91 is arranged on the front side of the upper part of the frame 1, and one or more are arranged along the direction parallel to the axis of the roller 2; the fertilizer funnel 91 should be provided with the same number corresponding to the grain seed funnel 4 to correspond to each grain Fertilization of seeds can save fertilizer and ensure the fertility required by grain seeds, which is more economical and practical. See Picture 10 , The shaft tube 92 passes through the lower part of the fertilizer hopper 91, and the shaft tube 92 is in a sealed fit with the lower opening of the ferti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com