an automatic seeder

A planter, automatic technology, applied in the direction of spaced quantitative sowing machinery, etc., can solve problems such as complex structure, complex operation process, and numerous equipment components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

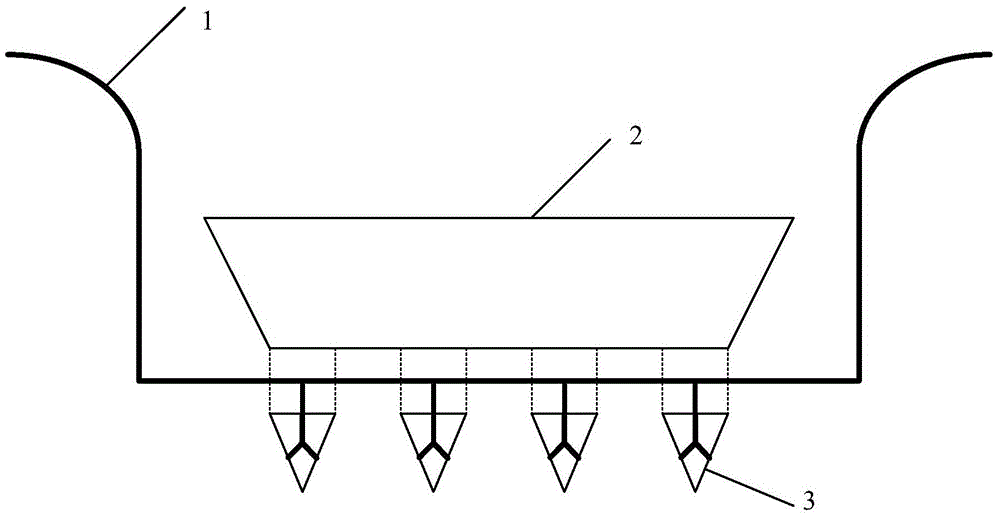

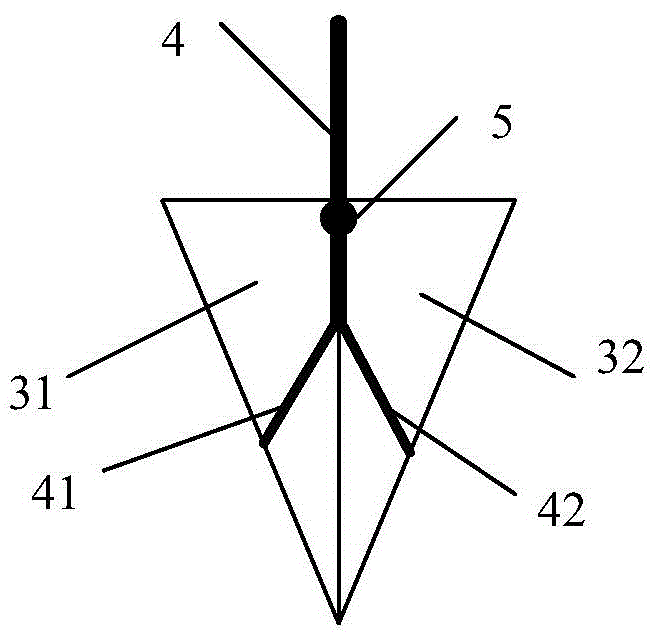

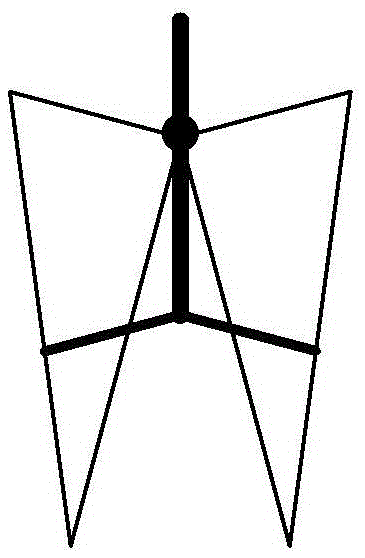

[0019] like Figure 1 to Figure 3 as shown, figure 1 It is a structural schematic diagram of an automatic seeder proposed by the present invention; figure 2 It is a structural schematic diagram when the seed delivery pipe of an automatic seeder proposed by the present invention is closed; image 3 It is a structural schematic diagram of an automatic seeder proposed by the present invention when the seed delivery pipe is opened.

[0020] refer to Figure 1 to Figure 3 , the embodiment of the present invention provides an automatic seeder, comprising: a frame 1; a seed cup 2, arranged on the frame 1, for holding seeds to be sown; a seed delivery tube 3, composed of the first half The cup 31 and the second half cup 32 are formed, the upper end of the seed delivery pipe 3 communicates with the seed cup 2, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com