Multifunctional printing and scraping mechanism

A multi-functional, scraper technology, applied in printing presses, rotary printing presses, printing and other directions, can solve the problems of single function and inability to apply multiple printing processes, and achieve the effect of simplifying the structure and ensuring accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

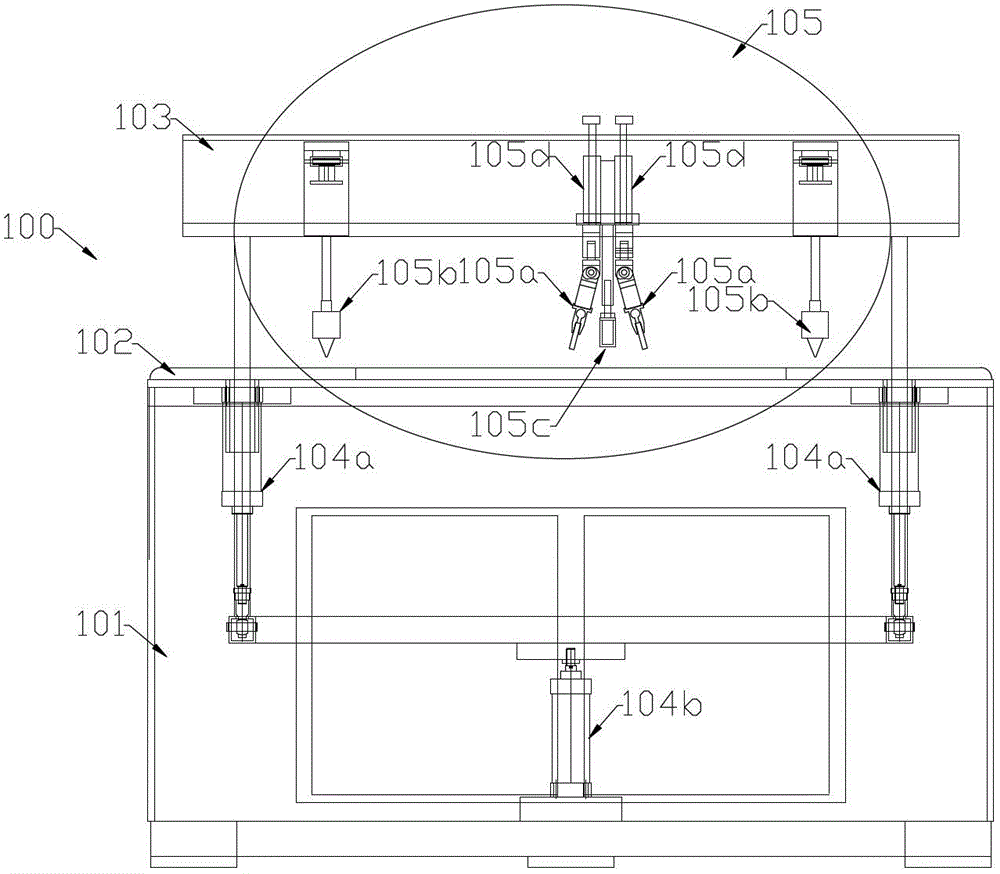

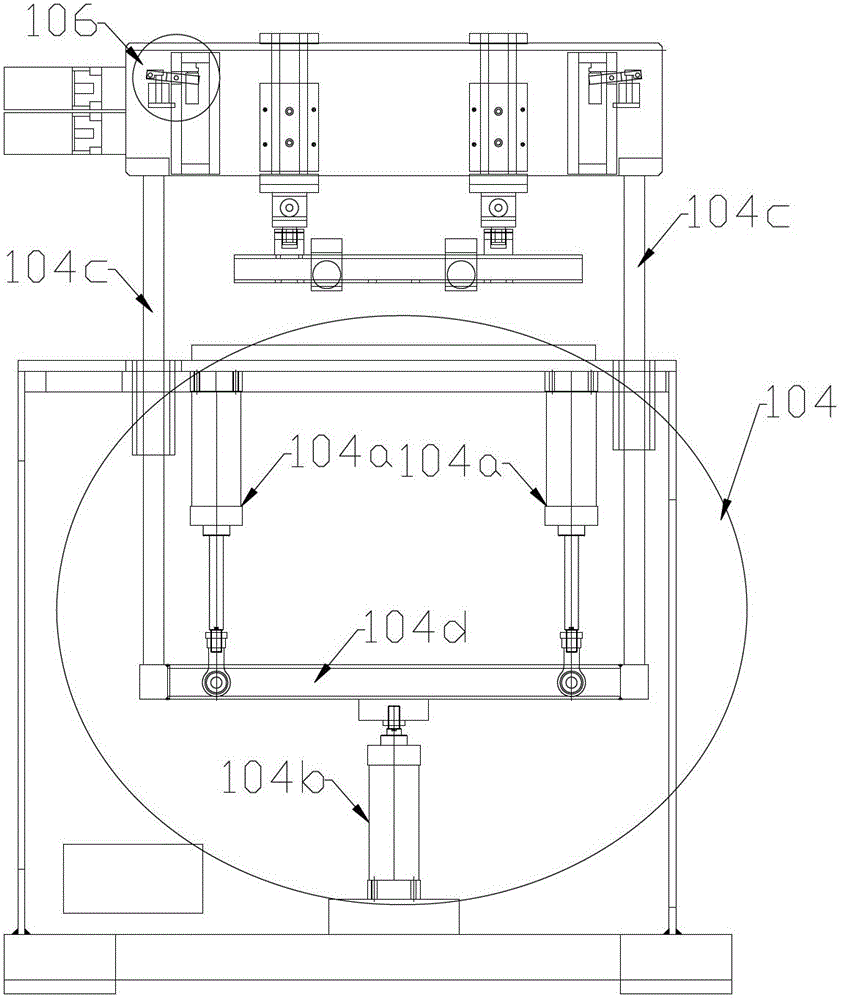

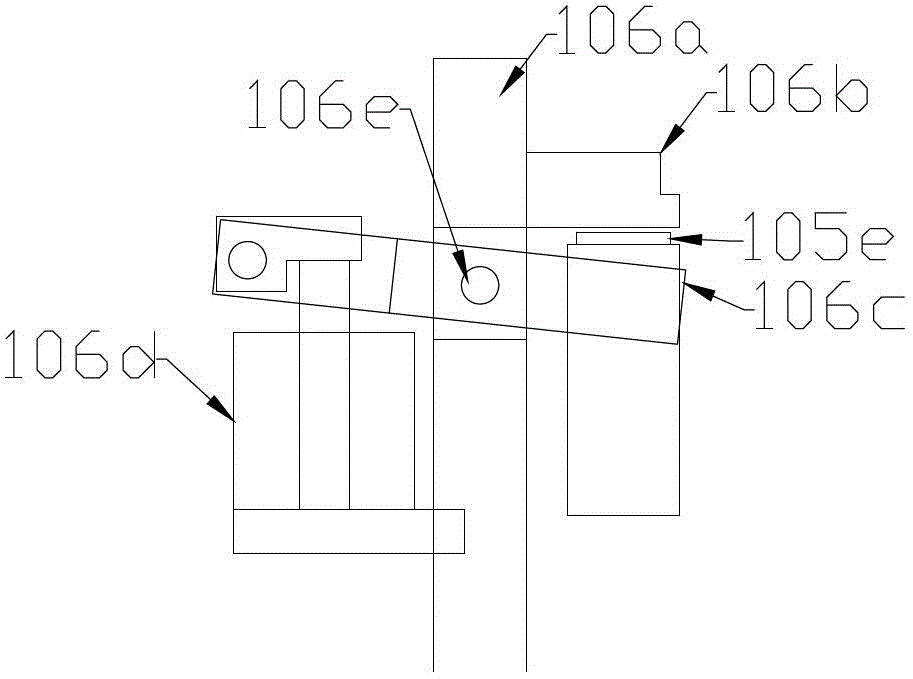

[0032] see figure 1 and 2 , the multifunctional printing and squeegee coating mechanism 100 provided by the present invention includes a cabinet 101 , a workbench 102 , a bracket 103 , a linkage mechanism 104 and a squeegee coating mechanism 105 .

[0033] The chassis 101 serves as the main structure of the entire printing mechanism, and the interior of the chassis 101 is hollow, and is mainly used for arranging electrical parts required for printing equipment control.

[0034] The workbench 102 is a specific implementation component for the mechanism to realize various printing processes, and it is arranged on the chassis 101 . The workbench 102 is a steel plate with a certain thickness or a hardened aluminum plate, on which a number of pores...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com