Wire stranding machine tensioning device facilitating adjustment of extending length of wire stranding rod

A technology of tensioning device and extension length, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of complex structure, complex adjustment process, unfavorable production efficiency of stranding machine, etc., and achieve simple tensioning force, The effect of meeting the needs of the production process and reducing the possibility of wire breakage or slack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

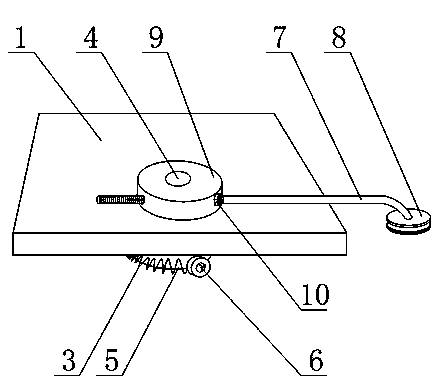

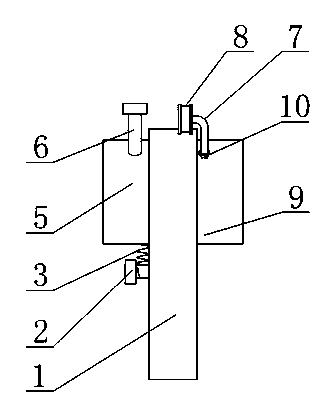

[0028] Such as figure 1 and figure 2 As shown, the tightening device of the twisting machine that is convenient for adjusting the extension length of the twisting rod includes a flat plate-shaped seat plate 1 and a wire tensioning device installed on the seat plate 1. The wire tensioning device includes a rotating shaft 4, a spring 3. The first disc 5, the second disc 9 and the stranding rod 7, the seat plate 1 is provided with a circular through hole, the rotating shaft 4 and the circular through hole form a clearance fit, and the two ends of the rotating shaft 4 are opposite to each other Protruding from both sides of the seat plate 1, the first disc 5 and the second disc 9 are respectively fixedly connected to the two ends of the rotating shaft 4, and the first disc 5 and the second disc 9 are respectively located on the sides of the seat plate 1. On both sides, one end of the spring 3 is fixedly connected to the side of the first disc 5, and the other end of the spring 3...

Embodiment 2

[0031] The present embodiment is further limited on the basis of embodiment 1, as figure 1 and figure 2 As shown, it also includes a first spring bolt 2, the seat plate 1 is provided with a first internally threaded hole, the first spring bolt 2 is threadedly fitted with the first internally threaded hole, and the number of the first internally threaded hole More than one, the first internally threaded holes are arranged on the seat plate 1 below the first disk 5, and the first internally threaded holes are distributed in the same vertical direction, the fixed connection point between the spring 3 and the seat plate 1 is at the One spring bolt 2 on.

[0032] Also includes a second spring bolt 6, the side of the first disc 5 is provided with a second internally threaded hole, the second spring bolt 6 is threadedly fitted with the second internally threaded hole, and the second internally threaded hole The number is 8, which are evenly distributed on the side of the first dis...

Embodiment 3

[0035] The present embodiment is further limited on the basis of embodiment 1, as figure 1 and figure 2 As shown, a roller 8 is also included, and the roller 8 is fixedly connected to the free end of the strand rod 7 .

[0036]The set roller 8 is used to support the wire, that is, when the wire passes through the present invention, the roller 8 rotates on the roller shaft, and the wire and the roller 8 do not move relative to each other, which is conducive to protecting the wire, that is, preventing the wire from wearing when passing through the present invention.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap