Die plate

A formwork and mold technology, applied in the field of formwork, can solve the problems of mold deformation, increased wear, etc., and achieve the effect of reduced length, reduced structural space, and avoiding replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

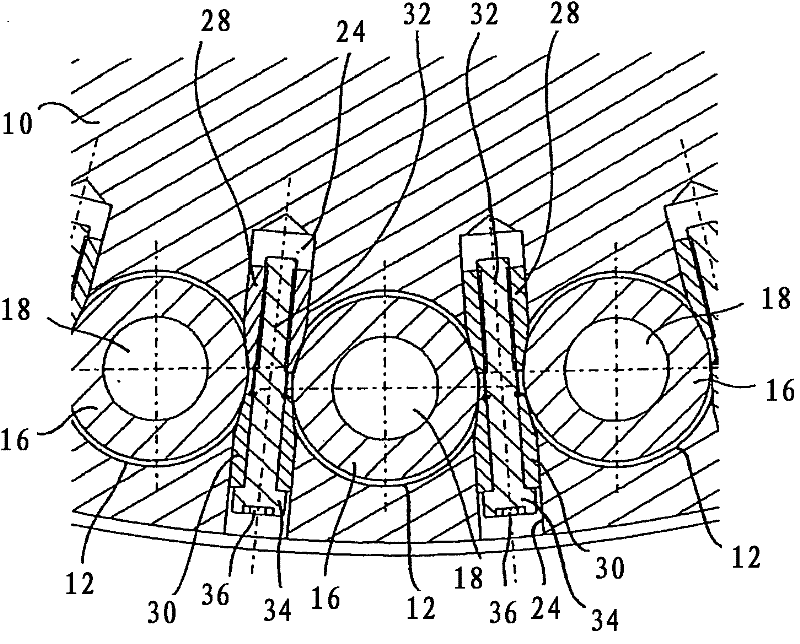

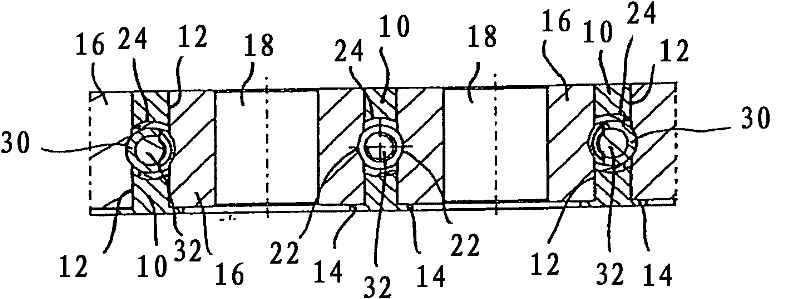

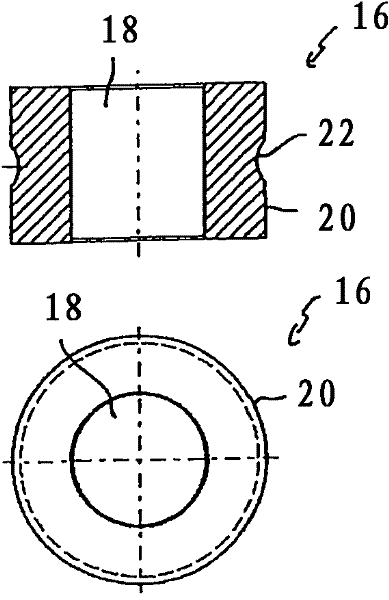

[0024] In the drawings, like reference numbers refer to like objects, unless otherwise indicated. figure 1 A portion of formwork 10 of the present invention is shown in horizontal section. figure 2 Parts of the formwork 10 of the present invention are also shown in vertical section. Template 10 is part of the rotor of a rotary tablet press (not shown). The template 10 shown in the example is designed to have a circular shape and can be rotated together with the rotor about a vertical axis of rotation. The formwork 10 has a plurality of die holes 12 which are distributed at regular intervals along the circumferential direction of the formwork 10 . exist figure 1 and 2 Among them, it can be seen that the die hole 12 is a cylindrical hole, and they are in figure 2 Each of them has an annular ring 14 at its lower end. The cylindrical mold 16 accommodated in the respective hole 12 rests in each case with its underside on the collar 14 of the hole 12 associated therewith. T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap