Automatic retractable heat dissipation frame of electric soldering iron

An automatic telescopic, electric soldering iron technology, applied in soldering irons, auxiliary devices, metal processing equipment, etc., can solve problems such as energy waste, easy oxidation of soldering iron tips, and short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

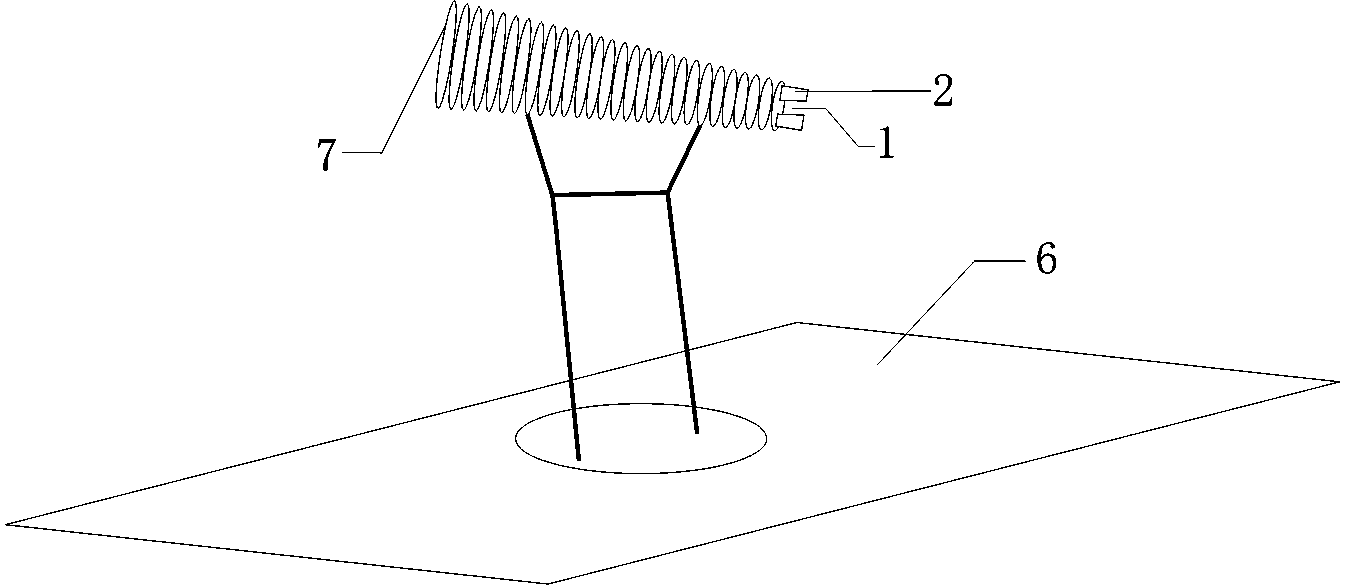

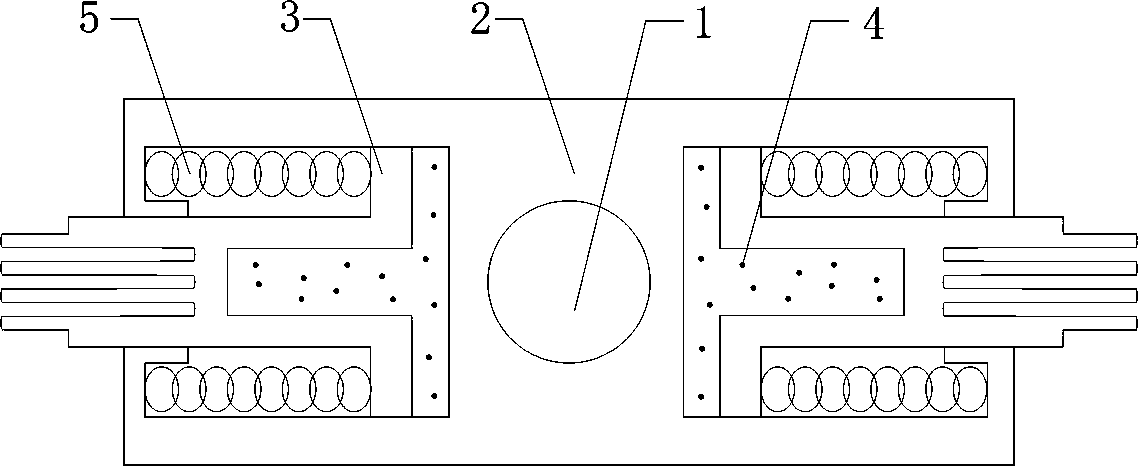

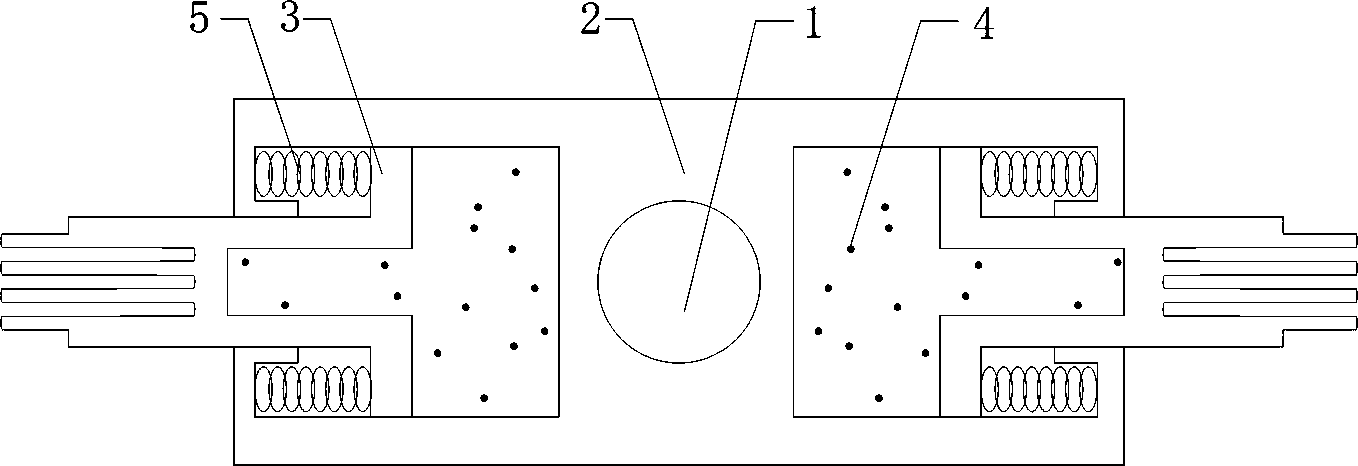

[0012] The present invention is a two-stage telescopic electric soldering iron cooling frame, which is composed of: a heat conduction hole 1, a main body 2, a cooling block 3, a wax body 4, a spring 5, a soldering iron frame 6, and a sleeve 7.

[0013] exist figure 1 Among them, the soldering iron frame 6 is connected with the sleeve 7 by means of a support rod, and the main body 2 is installed at the end of the sleeve 7 .

[0014] exist figure 2 Among them, a heat conduction hole 1 is designed in the middle of the main body 2. With the heat conduction hole 1 as the center, a heat dissipation block 3 is installed on each side. The middle of the heat dissipation block 3 and the main body 2 is filled with a wax body 4. Each side is equipped with a spring 5.

[0015] In the normal temperature state of the heat conduction hole 1, the wax body 4 does not expand, and the spring 5 pushes the cooling block 3 to the middle of the main body 2, so that the cooling block 3 shrinks insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com