A special slice material for biodegradable non-woven fabrics and preparation method thereof

A biodegradable, non-woven fabric technology, applied in the manufacture of rayon, textiles and paper, single-component polyester rayon, etc., can solve problems such as melt fracture, low melt index, and high brittleness of finished products, and achieve accelerated Large elongation at break, increased melt index, and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

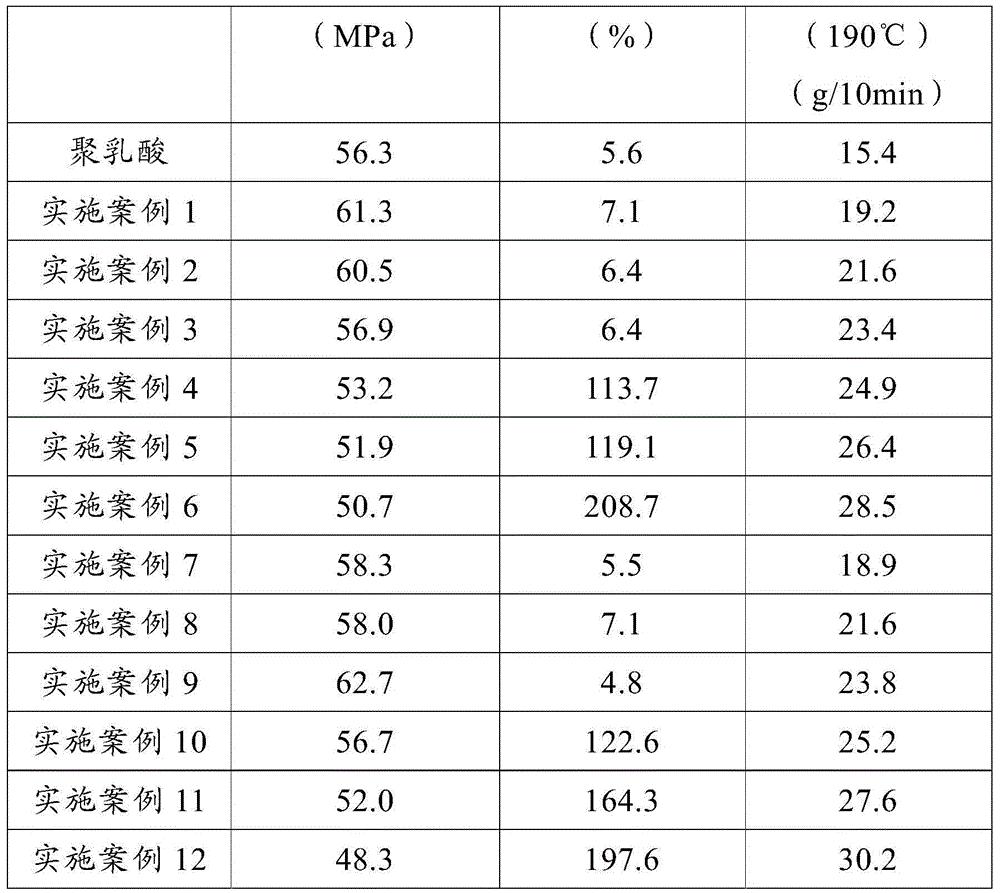

[0023] The present invention provides a kind of preparation method of biodegradable non-woven special chips, comprising:

[0024] Using polylactic acid and poly(2-ethyl-2-oxazoline) as raw materials, after drying at 50°C to 70°C for 6-12 hours, melt blending in a mixing equipment to obtain the biodegradable Chips for non-woven fabrics.

[0025] Poly(2-ethyl-2-oxazoline), also known as poly(N-propionylethyleneimine), the English name is (poly(2-ethyl-2-oxazoline), abbreviated as PEOX, which belongs to the polymerization of ethyleneimine The substance is prepared by cationic ring-opening polymerization of 2-ethyl-2-oxazoline (abbreviated as EOX), and is an amorphous polymer with good thermal stability. So far, on the use of poly(2-ethyl There have been no reports at home and abroad on the related research on improving the fluidity and toughness of polylactic acid (yl-2-oxazoline).

[0026] In the embodiment of the present invention, based on 100 parts by weight of polylactic a...

Embodiment 1

[0032] Weigh each component according to the following parts by mass:

[0033] 100 parts by weight of polylactic acid; 0.5 parts by weight of poly(2-ethyl-2-oxazoline) 50000 molecular weight.

[0034] The preparation process is as follows:

[0035] The above components were dried in a vacuum oven at 50° C. for 12 hours. The dried components were melt-blended in an internal mixer in proportion, the blending temperature was 180°C, the blending time was 3 min, and the rotation speed was 60 rad / min to obtain a blend.

[0036] The melt index of the blend was measured using an XNR-400B melt flow rate tester (diameter of the outlet is Φ2.095±0.005mm, length of the outlet is 8.000±0.025mm), the temperature was 190°C, and the pressure was 2160g.

[0037] Press the blend into a plate on a flat vulcanizer, cut it into a dumbbell-shaped sample, and test the mechanical properties with a tensile testing machine: the length of the sample is 75mm, the width is 4±0.1mm, and the thickness is ...

Embodiment 2

[0039] Weigh each component according to the following parts by mass:

[0040] 100 parts by weight of polylactic acid; 1 part by weight of poly(2-ethyl-2-oxazoline) 50000 molecular weight.

[0041] The preparation process is as follows:

[0042]The above components were dried in a vacuum oven at 50° C. for 12 hours. The dried components were melt-blended in an internal mixer in proportion, the blending temperature was 180°C, the blending time was 3 min, and the rotation speed was 60 rad / min to obtain a blend.

[0043] The melt index of the blend was measured using an XNR-400B melt flow rate tester at a temperature of 190° C. and a pressure of 2160 g.

[0044] Press the blend into a plate on a flat vulcanizer, cut it into a dumbbell-shaped sample, and test the mechanical properties with a tensile testing machine: the length of the sample is 75mm, the width is 4±0.1mm, and the thickness is 1±0.1mm. The speed was 25mm / min, the experiment was repeated 6 times, and the average v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com