Method and device for sterilising and device for blow-moulding containers

A blow molding and container technology, which is applied in the field of sterilization and equipment and blow molding equipment for containers, can solve the problem of high cost and achieve the effect of high production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

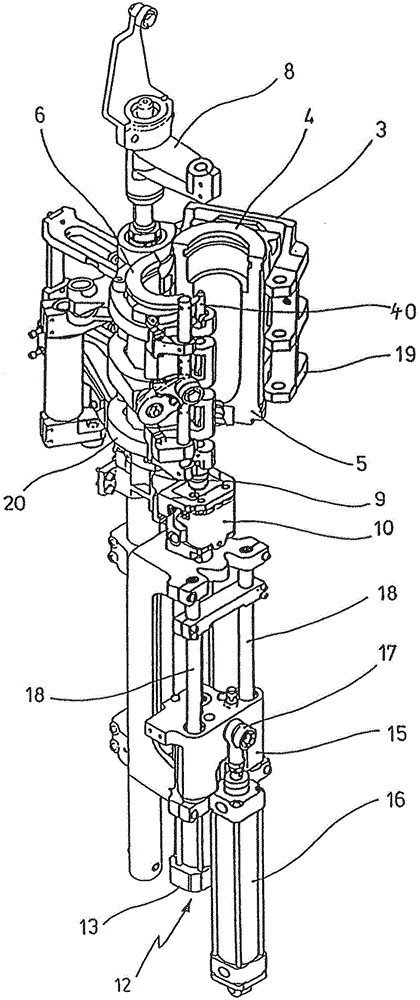

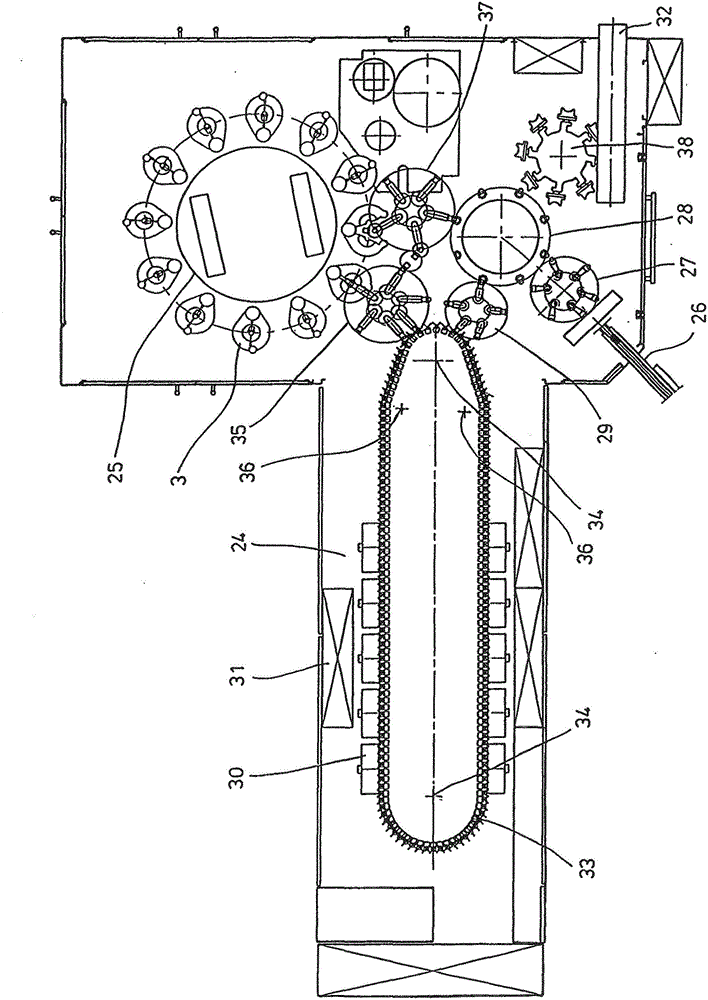

[0045] Before explaining the detailed structure of the device for sterilizing the preforms ( 1 ) by using a sterilizing medium and before explaining the specific insertion of the corresponding device into a blow molding machine, it should first be described subsequently A schematic structure of a blow molding machine.

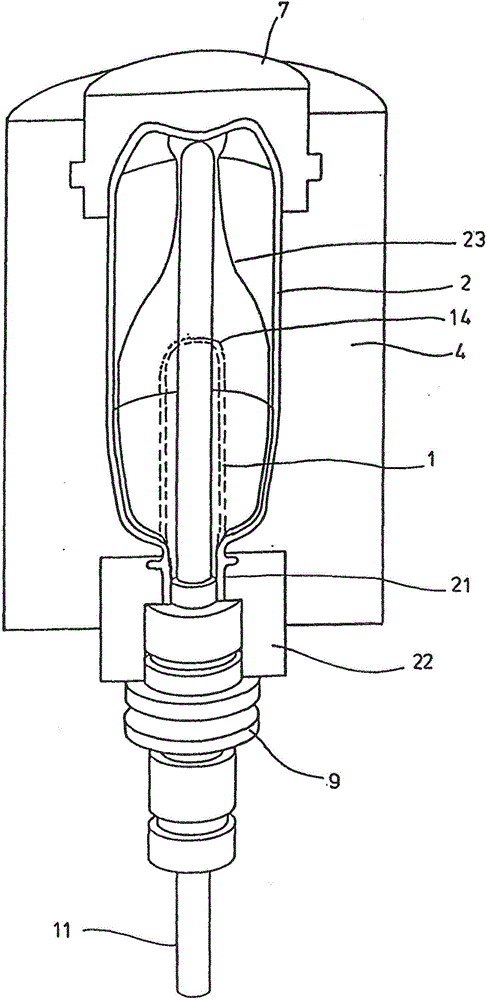

[0046] The principle structure of the device for deforming a preform (1) into a container (2) is in figure 1 with figure 2 shown in .

[0047] The device for forming containers (2) basically comprises a blow molding station (3) provided with a blow mold (4) into which a preform (1) can be inserted. The preform ( 1 ) can be an injection molded part made of polyethylene terephthalate. In order to be able to insert the preform (1) into the blow mold (4) and to be able to remove the finished container (2), the blow mold (4) consists of mold halves (5, 6) and a bottom part (7 ), the bottom part can be positioned by a lifting device (8). The preform (1) can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com