Transit trolley for components and parts

A technology of parts and trolleys, applied in trolleys, motor vehicles, multi-axis trolleys, etc., can solve problems such as deformation of auxiliary equipment, inability to meet the versatility of other parts, and bumps on the surface of the body-in-white

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

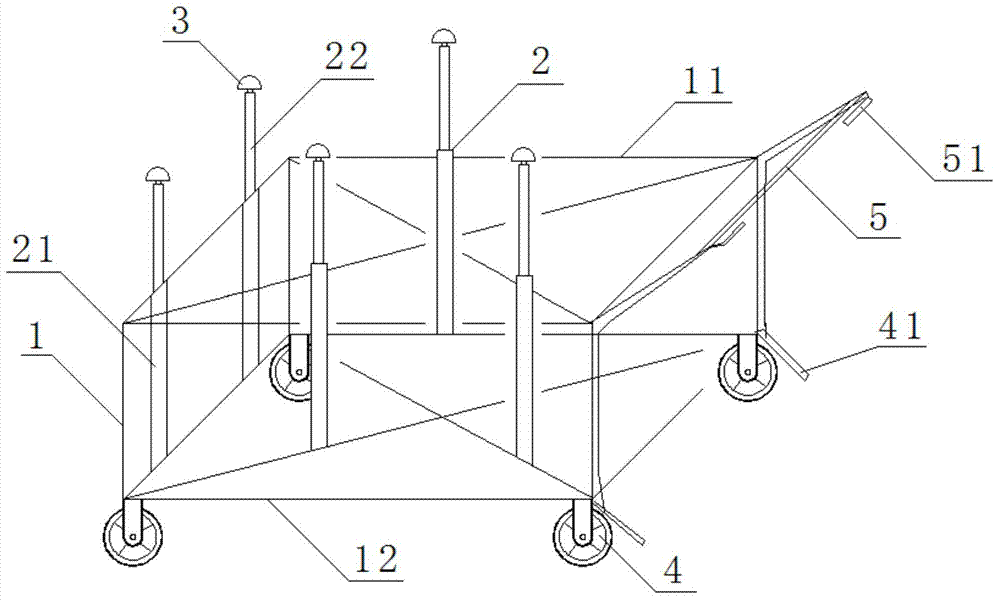

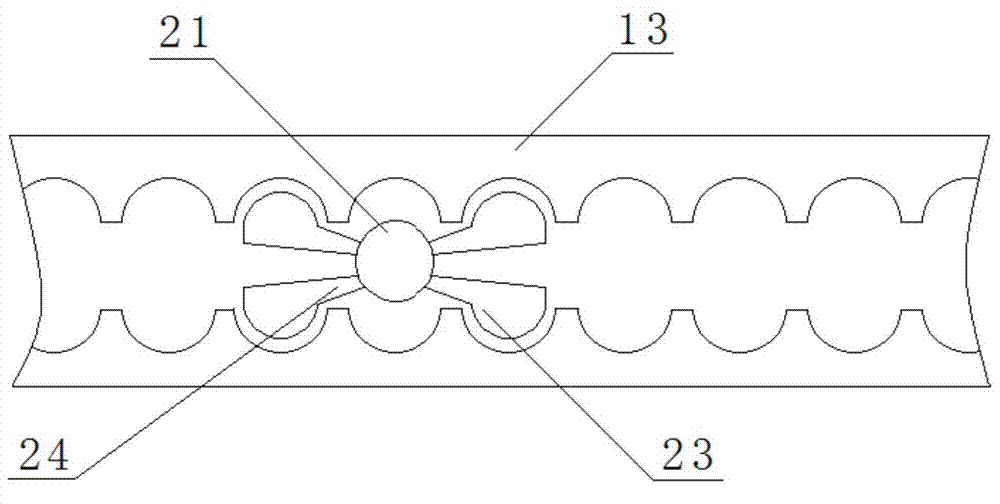

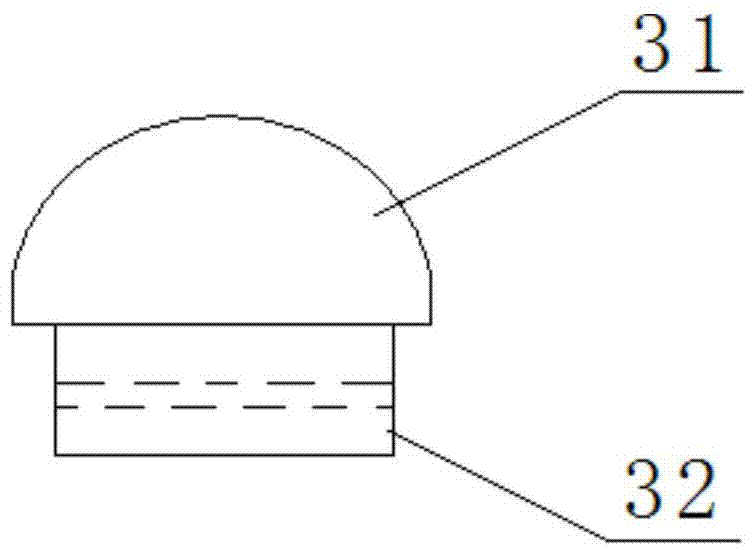

[0016] Figure 1-3 It is a structural schematic diagram of the transfer trolley used for parts in the present invention, figure 2 It is a structural schematic diagram of the cooperation between the guide rail and the outer sleeve, image 3 Schematic diagram of the support pad structure. Depend on Figure 1-Figure 3 It can be seen from the combination that this kind of transfer trolley for parts includes a frame 1, and the frame includes an upper frame 11 and a lower frame 12, and the upper frame 11 and the lower frame 12 are connected together by longitudinal support bars located at four corners. The four sides and two diagonals corresponding to the upper frame 11 and the lower frame 12 are respectively provided with a plurality of uprights 2 penetrating the frame 1. The uprights 2 include an outer sleeve 21 and an inner sleeve whose end is located inside the outer sleeve 21. sleeve 22, and the size of the overlapping portion of the inner sleeve 22 and the outer sleeve 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com