Aquatic freezer

A technology for aquatic products and ice holes, used in coolers, lighting and heating equipment, food preservation, etc., can solve the problems of water sloshing out of the quick-freezing box and the weight of frozen products, and achieve the effect of reducing weight and transportation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

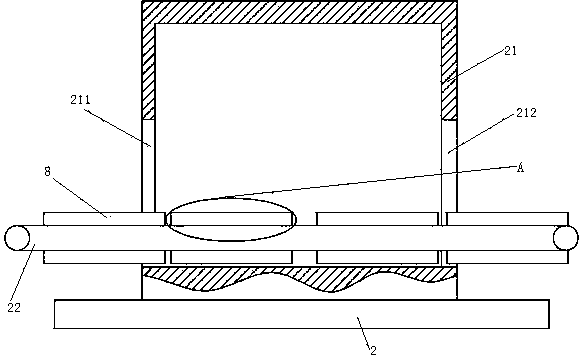

[0029] Embodiment one, see figure 1 , an aquatic freezing machine, comprising frame 2. A quick-freezing chamber 21 and a conveyor belt 22 are arranged on the frame 2 . The quick-freezing chamber 21 is an existing structure. The quick-freezing chamber 21 is provided with an inlet door 211 and an outlet door 212 . The conveyor belt 22 passes through the quick-freezing chamber 21 through the inlet door 211 and the outlet door 212 . The conveyor belt 22 is provided with several quick-freezing box support frames 8 distributed along the extending direction of the conveyor belt (8 are schematically drawn in this embodiment).

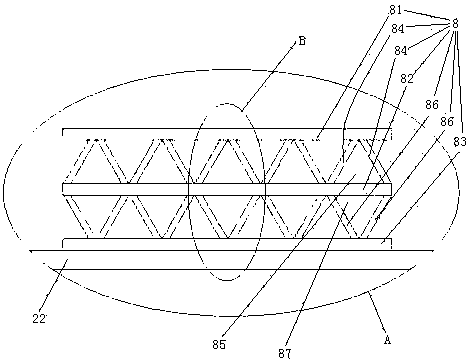

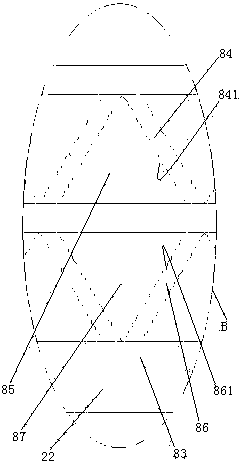

[0030] see figure 2 , the quick-freezer support frame 8 includes an upper base plate 81 , a middle base plate 82 and a lower base plate 83 distributed along the vertical direction. A number of inclined support plates 84 are provided between the upper base plate 81 and the middle base plate 82 . Several upper deformation channels 85 extending along the ho...

Embodiment 2

[0033] Embodiment two, see Figure 4 , The difference with the second embodiment is: the two ends of the upper deformation channel 85 and the lower deformation channel 87 are provided with end caps 80, so that the upper deformation channel 85 and the lower deformation channel 87 form a closed cavity. The upper inclined support plate between the adjacent upper deformation channels 85 in the upper inclined support plate 84, the lower inclined support plate between the adjacent lower deformation channels 87 in the lower inclined support plate 86, and the middle base plate 82 are located on the corresponding A damping channel 88 is provided at the position between the adjacent upper deformation channel and the lower deformation channel. Both the upper deformation channel 85 and the lower deformation channel 87 are filled with damping fluid (the damping fluid is not shown in the figure). The upper deformation channel 85 and the lower deformation channel 87 are provided with an ene...

Embodiment 3

[0036] Embodiment three, the difference with embodiment two is:

[0037] see Figure 6 , The outside of the quick-freezing chamber 21 is provided with a water tank 23 , a tube plate 24 and a water pump 25 . The water pump 25 is a quantitative pump. The inlet of water pump 25 is connected together with water tank 23. The outlet of the water pump 25 and the tube plate 24 are butted together.

[0038] The quick-freezing chamber 21 is provided with an ice hole forming mechanism 7 and an ice hole capping mechanism 6 .

[0039] The ice hole forming mechanism 7 is located above the conveyor belt 22 . The ice hole forming mechanism 7 includes a first lifting mechanism 71 , a first top frame 72 , an ice hole shaping column 73 and a frozen product lifting resistance frame 74 . The first lifting mechanism 71 is an air cylinder. The first lifting mechanism 71 suspends the first top frame 72 on the top wall of the quick-freezing chamber 21 . The upper end of the ice hole shaping col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com