Electric constant temperature flat packaging machine

A packaging machine and constant temperature technology, applied in packaging, transportation packaging, packaging protection, etc., can solve the problems of continuous stepless adjustment of temperature classification settings, no error prevention function, single working mode, etc., to achieve compact structure and easy avoidance The effect of misoperation and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

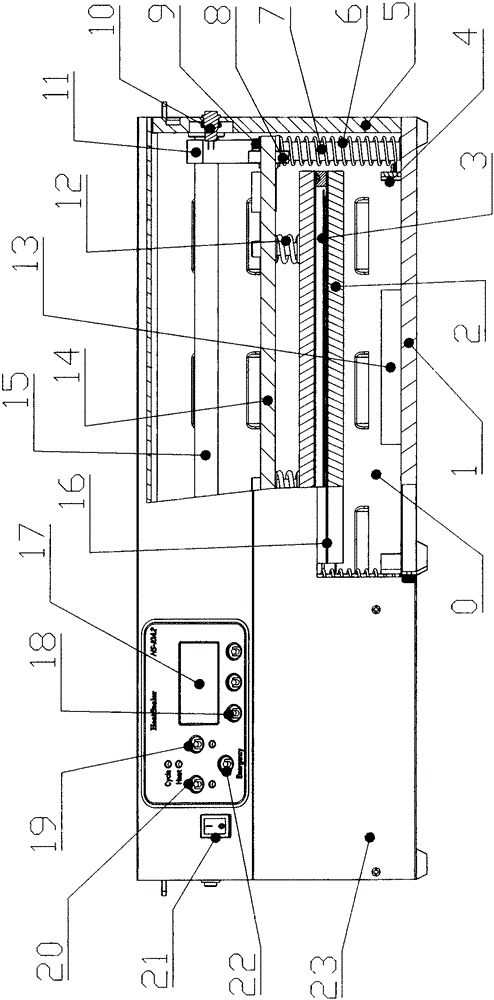

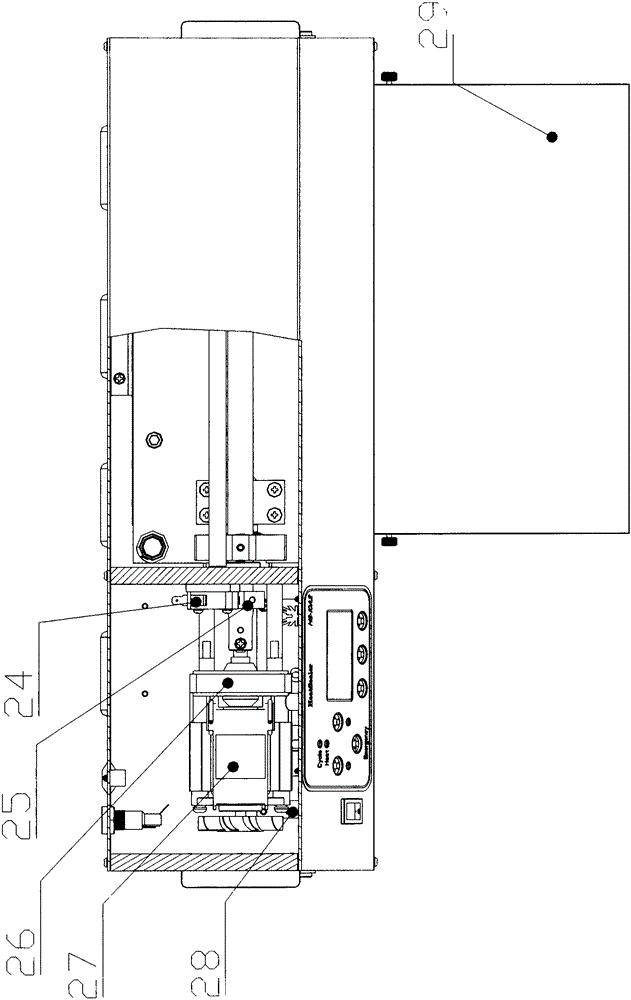

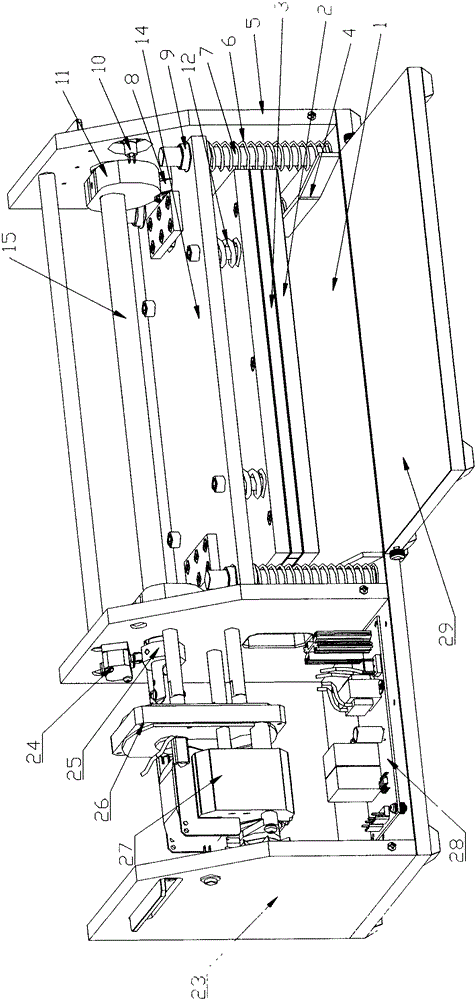

[0038] like Figure 1 ~ Figure 3 Shown: an electric constant temperature flat-panel packaging machine disclosed in this embodiment, the electric heating plate assembly is used to heat the hot-melt film adhesive on the object to be packaged;

[0039] The lifting component is used to drive the electric heating plate component to move up and down;

[0040] A power component is used to provide power to the lifting component;

[0041] A switch assembly, used to connect the starting circuit of the power assembly;

[0042] The control circuit is used to adjust the temperature of the electric heating plate assembly and keep the electric heating plate assembly in a constant temperature state within a certain temperature range, and to start and close the power assembly;

[0043] The shell 23 and the bottom plate 1 are used to install and accommodate the above-mentioned electric heating plate assembly, lifting assembly, power assembly, switch assembly and control circuit.

[0044] It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com