Unilaterally adjustable type threading die

An adjustable die technology, applied in metal processing equipment, thread cutting devices, manufacturing tools, etc., can solve problems such as unqualified threads, inability to fine-tune, and product scrapping, achieving high precision and reducing scrapping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

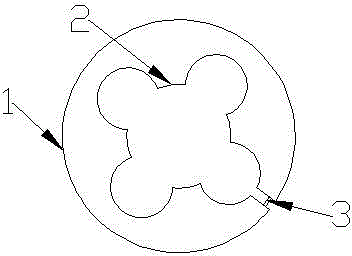

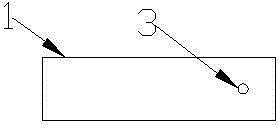

[0013] A single-sided adjustable die, such as figure 1 , figure 2 As shown, it includes a die body 1, a blade portion 2, and an adjustment device 3; the blade portion 2 is on the inner side of the die body 1, and the adjustment device 3 is installed on one side of the die body 1 to form a single-side adjustable die.

[0014] The specific operation is as follows: First, insert the part that needs to be threaded into the die body 1, and rotate the adjustment device 3 to a suitable degree of tightness according to the material, and turn the part to be processed. thread.

[0015] In the present invention, as a variant embodiment, the number of blades on the blade portion can be freely designed. Therefore, the protection scope of the present invention is subject to the scope defined in the claims.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap