Special hoisting mechanism for nuclear main pump flywheel

A nuclear main pump and flywheel technology, applied in the field of hoisting tools, can solve the problems of bulky, ordinary hoisting tools that cannot be hoisted, and achieve the effect of ensuring stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

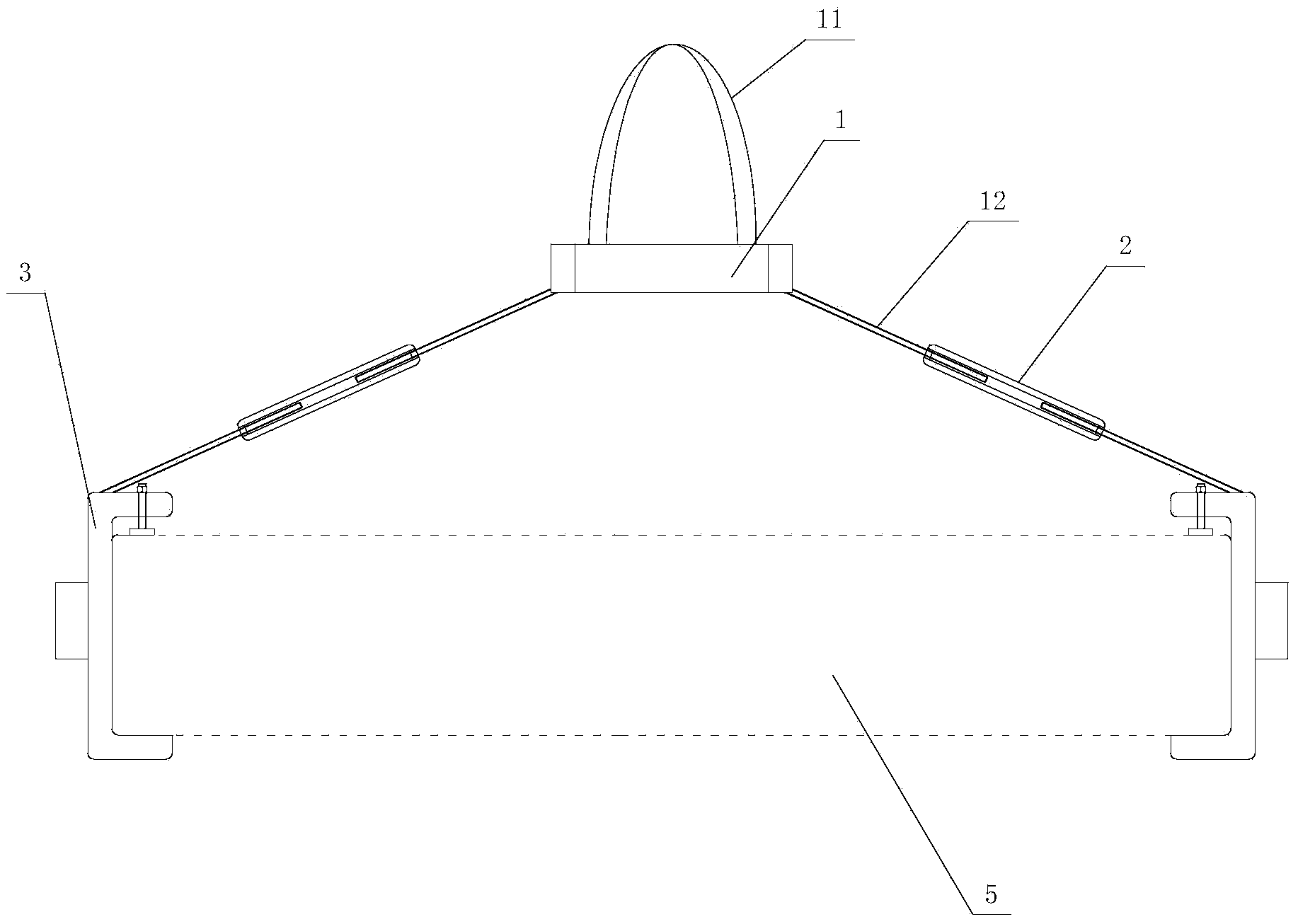

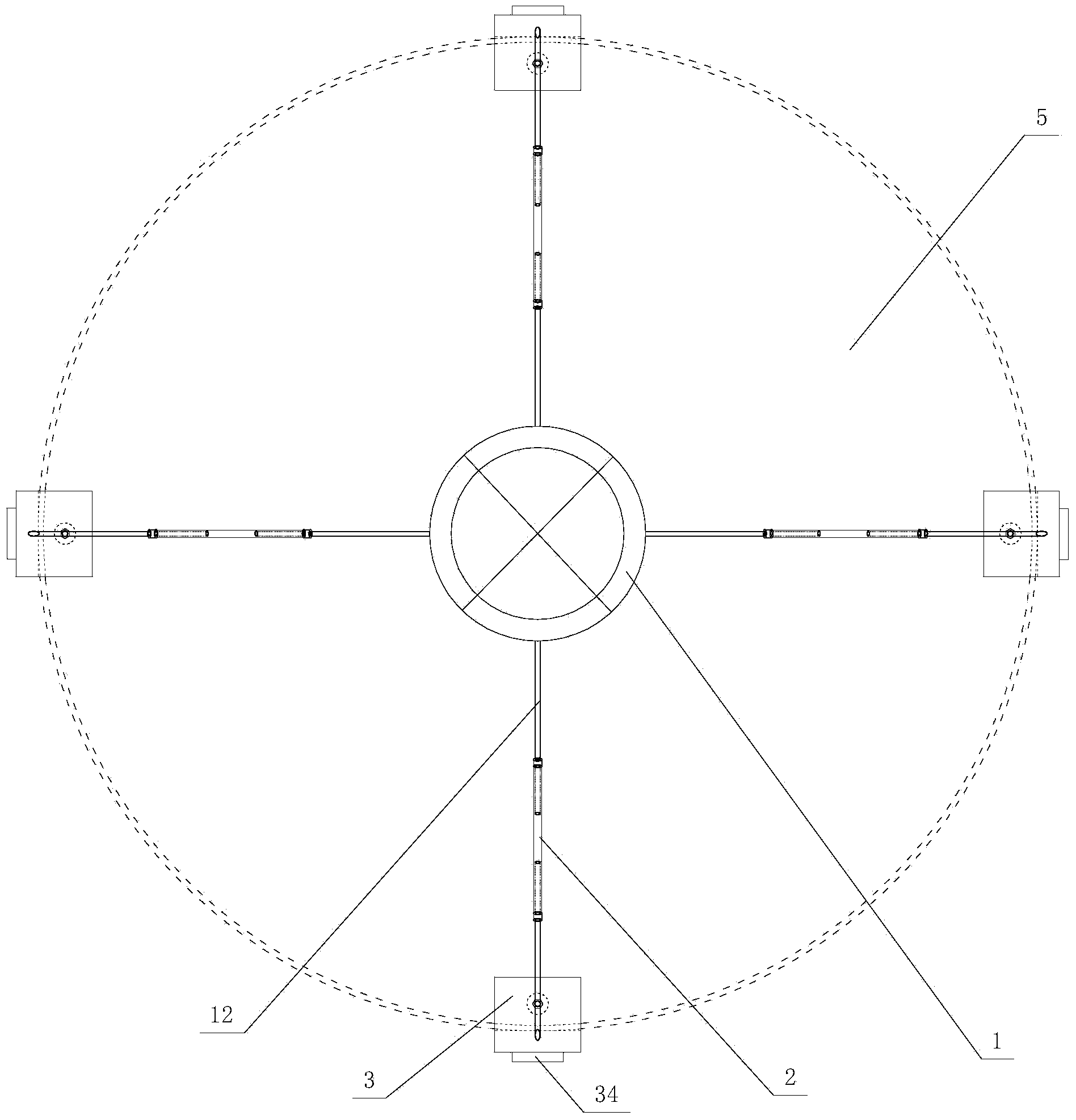

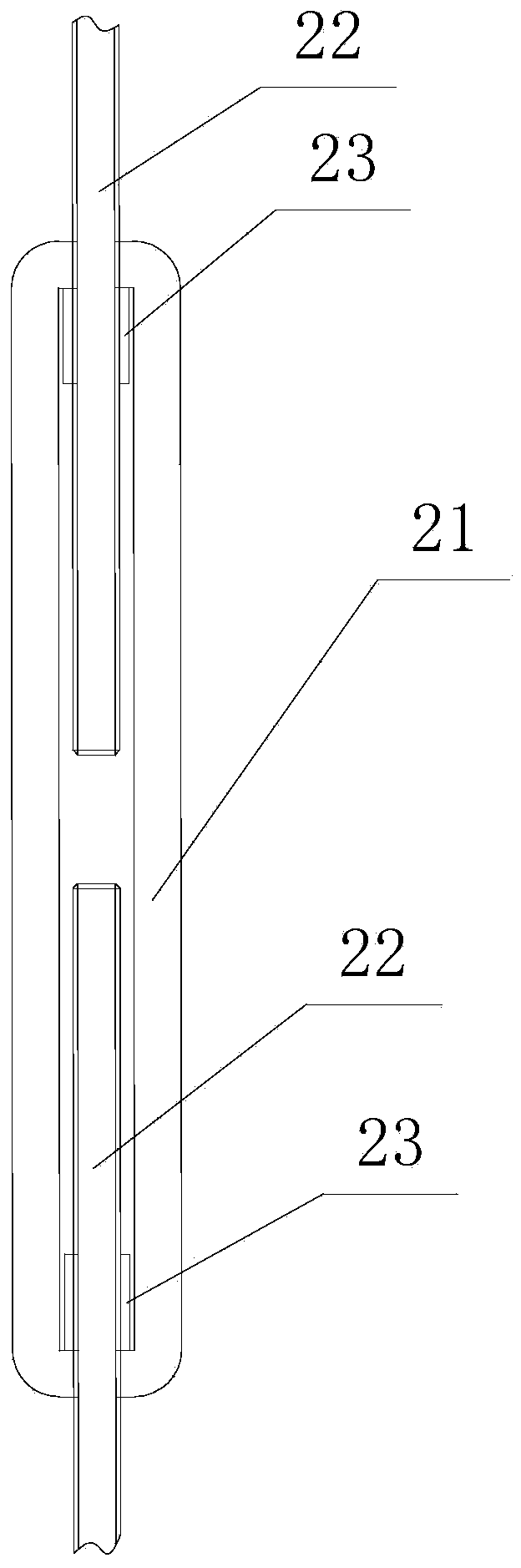

[0020] refer to Figure 1 to Figure 4 , the present invention provides a special hoisting mechanism for the nuclear main pump flywheel, which is used for hoisting the nuclear main pump flywheel 5, including a central load-bearing ring 1 and a concave clip 3 for clamping, on the upper bottom of the central load-bearing ring 1 is fixed a Ring 11, which is used for lifting, at least three cables 12 are evenly distributed circumferentially on the side wall of the central bearing ring 1, preferably four, and each cable 12 is provided with a turnbuckle 2 for adjusting the length; The clamping concave clamp 3 is fixed on the end of the cable 12, and the side wall of the concave clamp 3 is formed with a card slot 31 for clamping the nuclear main pump flywheel 5, and the top of the concave clamp 3 is provided with a communication slot 31 In the threaded hole, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com