Cable-drive steel wire rope connecting device

A technology for connecting devices and wire rope joints, applied in the direction of transmission elements or pulley ropes or cables, textile cables, belts/chains/gears, etc. Reliability, reduce control difficulty, reduce the effect of force intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

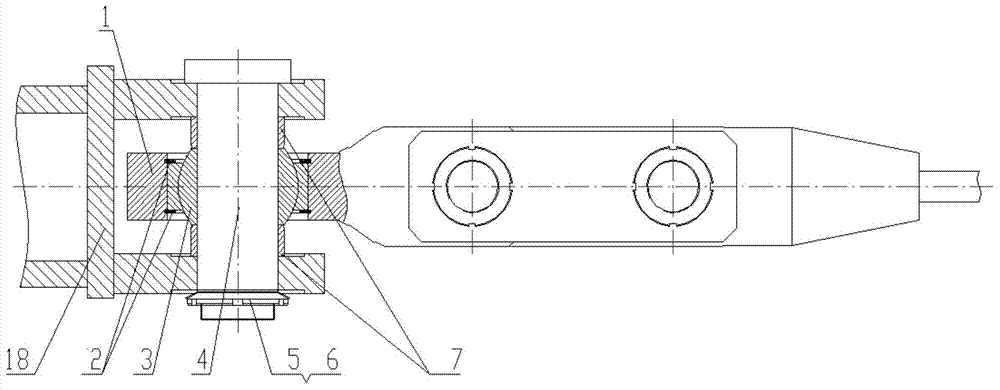

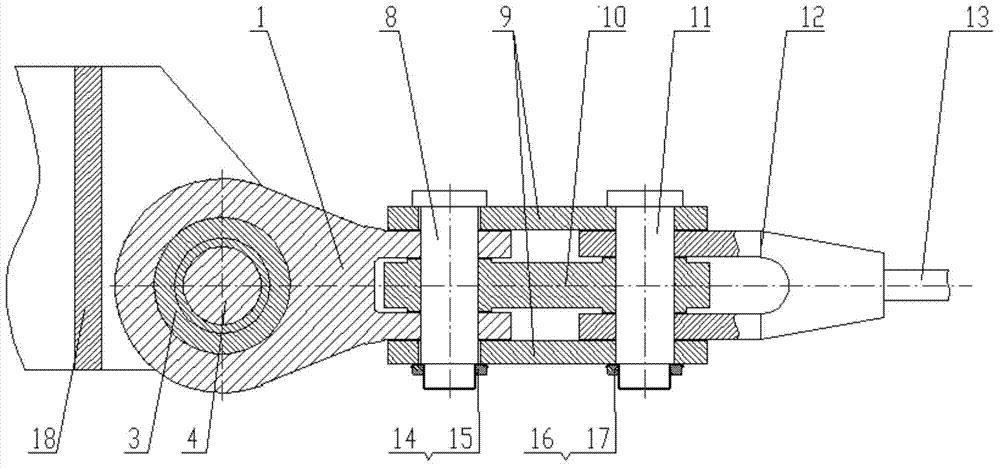

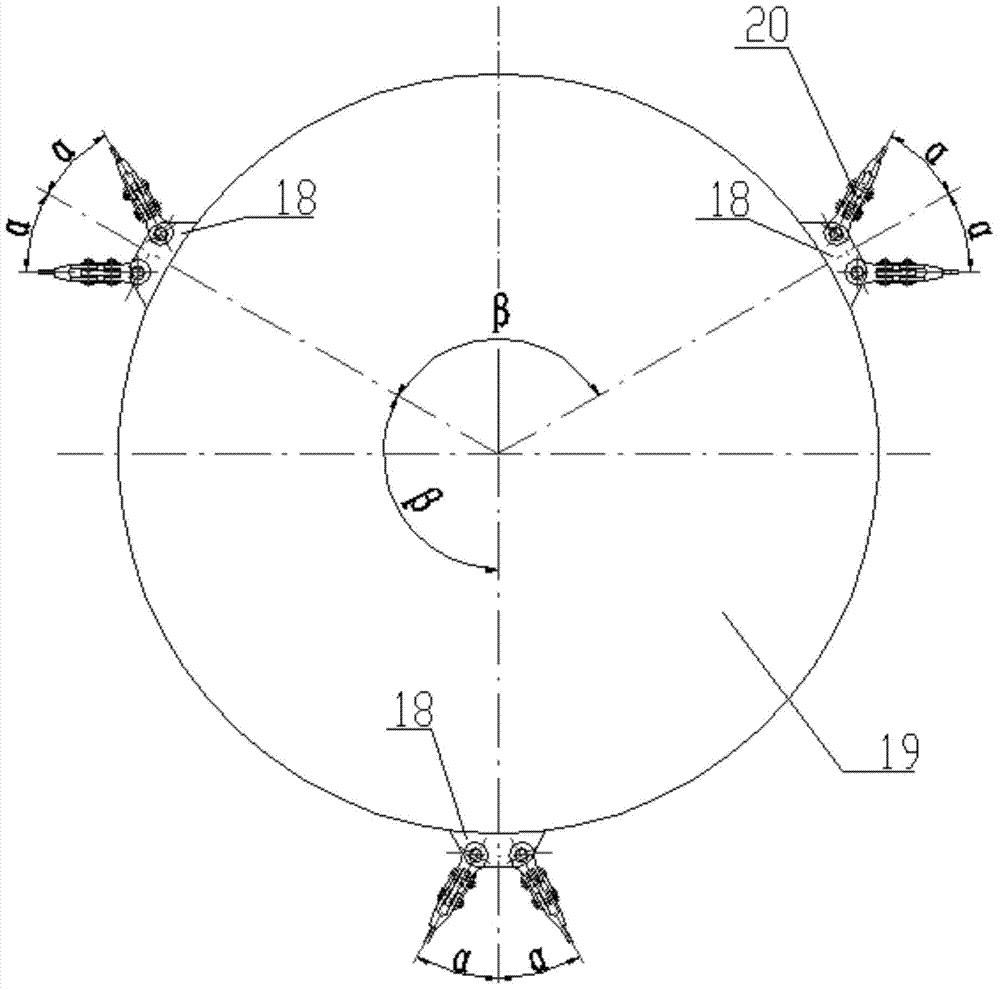

[0020] The embodiment is to drive the signal receiving device of the astronomical telescope—the cable-driven wire rope connection device of the feed cabin, including the fork 1, the retaining ring 2, the joint bearing 3, the pin shaft I4, the round nut I5, the washer I6, and the spacer 7 , pin shaft II8, protective plate 9, tension sensor 10, pin shaft III11, steel wire rope joint 12, steel wire rope 13, round nut II14, washer II15, round nut III16, washer III17 and connection support 18, the front part of fork 1 is Two horizontal parallel plates, the rear part is a connecting plate, the center of the two horizontal parallel plates in the front is provided with a pin hole, and the center of the rear connecting plate is provided with a joint bearing hole; the front part of the wire rope joint 12 is Two horizontal parallel plates, the front of the two horizontal parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com