Connection terminal and manufacturing method thereof

A technology for connecting terminals and manufacturing methods, which is applied in the field of connecting terminals and its manufacturing that can improve the reliability of contact points, can solve the problems that the contact reliability of terminals cannot be really effectively improved, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

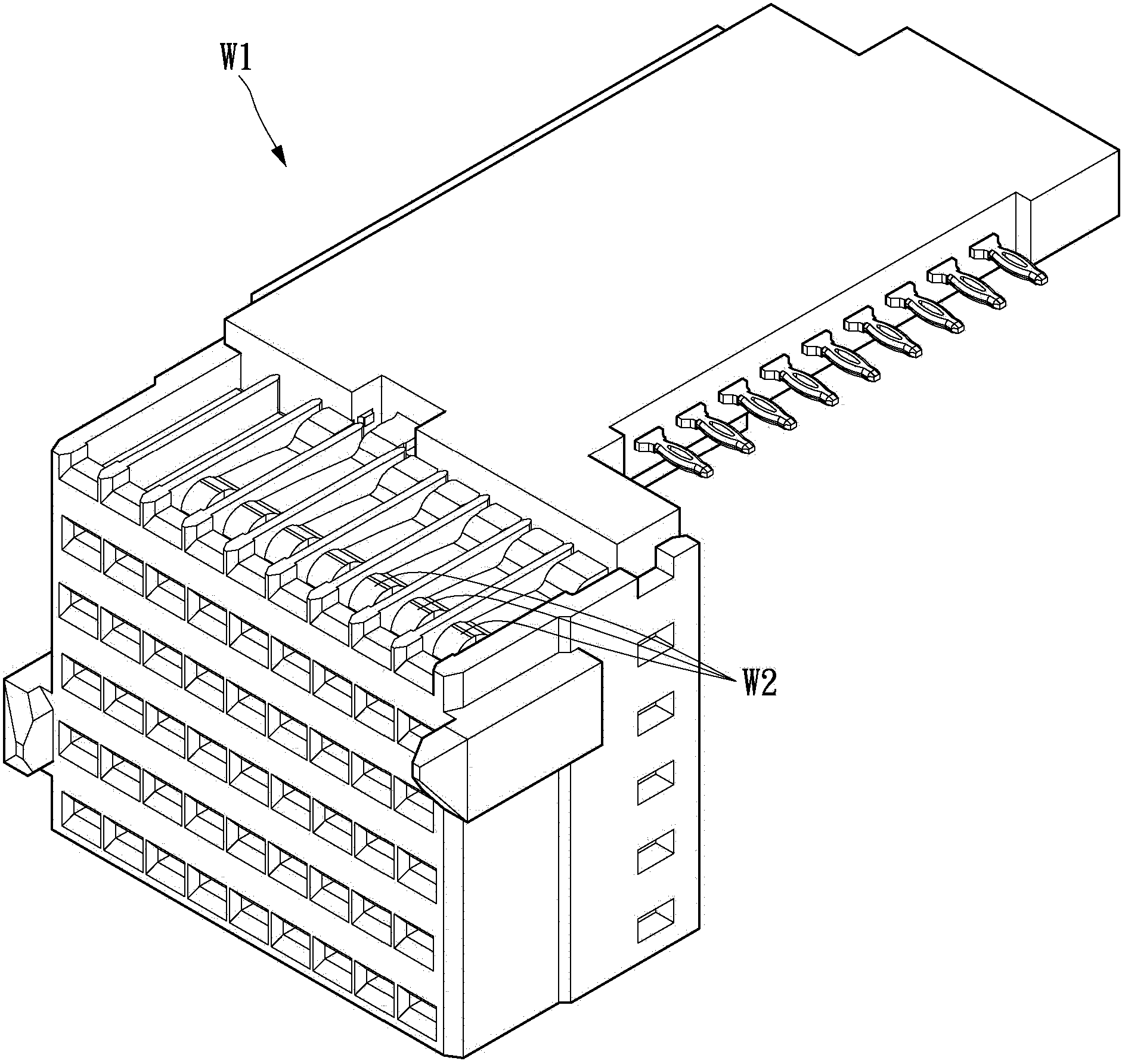

[0056] see Figure 4 , Figure 5A as well as Figure 6 As shown, the present invention provides a connection terminal 10 that improves the reliability of the contact point for use with a connector 1, but the type of the connector 1 is not limited, so as long as the connector 1 has the lifting contact of the present invention All connection terminals 10 with high reliability should belong to the protection category of the present invention.

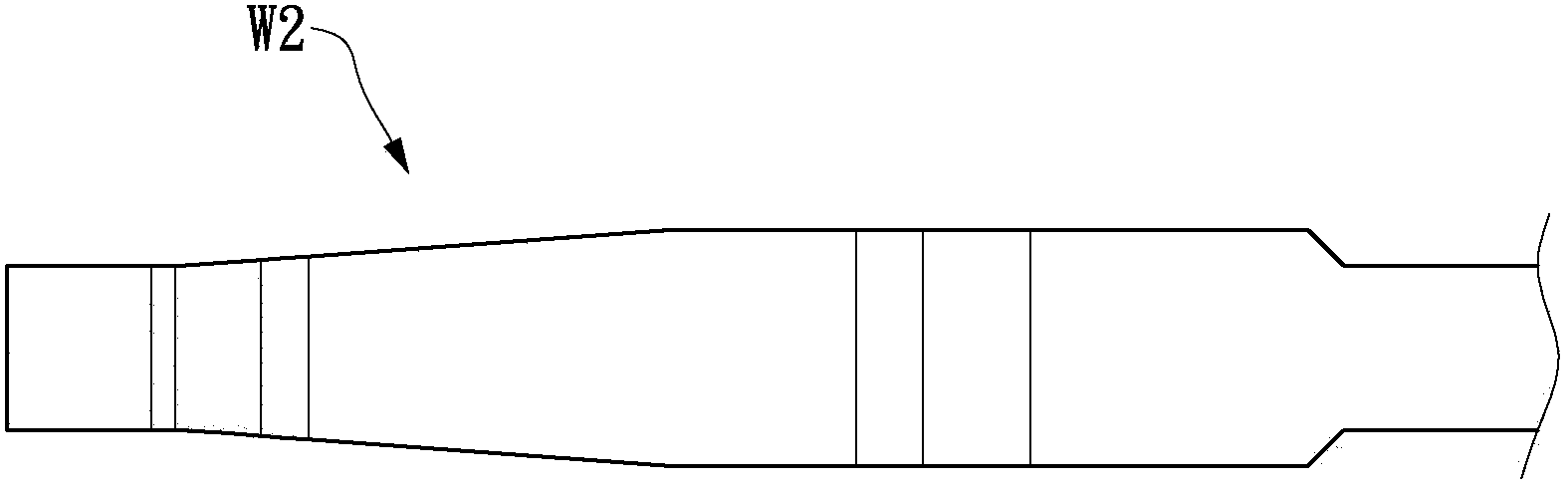

[0057] The connection terminal 10 includes a terminal base 11 , and at least extends from the terminal base 11 to include: a first contact unit 12 and a second contact unit 13 .

[0058] The first contact unit 12 includes a first contact arm 121 and a first contact end portion 122, and the second contact unit 13 includes a second contact arm 131 and a second contact end portion 132, wherein preferably, the first contact unit 12 and the second contact unit 13 can be parallel to each other and separated by a gap 14 , and the first contact...

no. 2 example

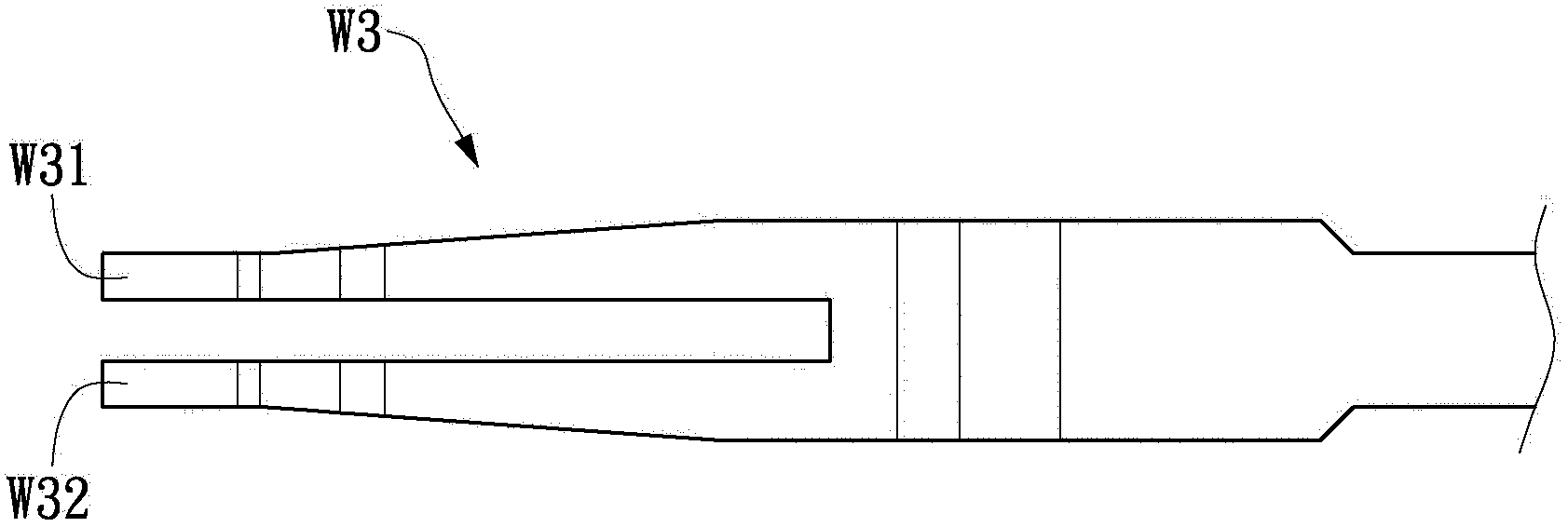

[0062] see Figure 7 , Figure 8A As shown, preferably, the protruding portion 123 of the present invention can only extend to the gap 14, and does not continue to extend to connect with the second contact arm 131. At this time, the protruding portion 123 further extends to the terminal base 11 and connects to the terminal base 11 connections. see Figure 9 As shown, the structure of this embodiment and the connection relationship between the various components also lead to the difference in the normal force (vertical axis) of the first contact unit 12 and the second contact unit 13, so as to improve the reliability of the terminal contact point.

[0063] see Figure 8B As shown, it is another variation of this embodiment, compared to Figure 8A , the protruding portion 123 may not only extend toward the gap 14 or the second contact arm 131 of the second contact unit 13, the protruding portion 123 may also extend from the first contact arm 121 toward the side away from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com