Flexible clamp based on magneto-rheological plaster

A technology of magnetorheological cement and flexible fixture, applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problems of poor settlement stability and limiting the use range of magnetorheological fluids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

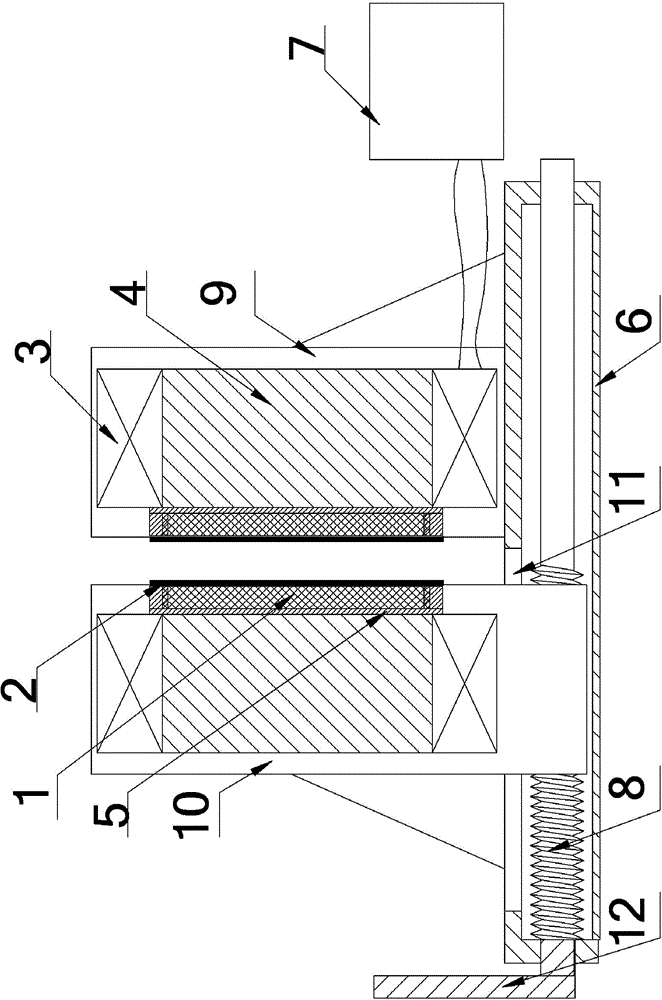

[0019] see figure 1 , is an embodiment of a flexible clamp based on magnetorheological cement, including a clamp seat 6, which is respectively provided with a fixed clamping body 9 and a movable clamping body 10, and the fixed clamping body 9 is welded and fixed On the fixture base 6, the movable clamping body 10 is slidably matched with the chute 11 provided on the clamping base 6, the bottom of the movable clamping body 10 is provided with a threaded hole, and a screw rod is axially positioned on the clamping base 6 8. In this embodiment, the screw rod 8 is supported on the fixture seat 6 through a thrust bearing, and a cavity for installing the screw rod 8 is provided in the fixture seat 6 . The screw rod 8 is threadedly engaged with the threaded hole of the movable clamping body 10 to form a screw nut mechanism. Further, a handle 12 is provided at one end of the screw rod 8 , which is convenient for turning the screw rod 8 to move the movable clamping body 10 toward the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com