Asymmetric frame series overhung tower climbing machine support system

A tandem, asymmetrical technology, applied in the direction of cranes, etc., can solve the problems that the tower crane suspension climbing support system cannot be symmetrically installed with horizontal support rods, and cannot fully meet the needs of safe and reliable support for tower cranes. The effect of improving adaptive capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

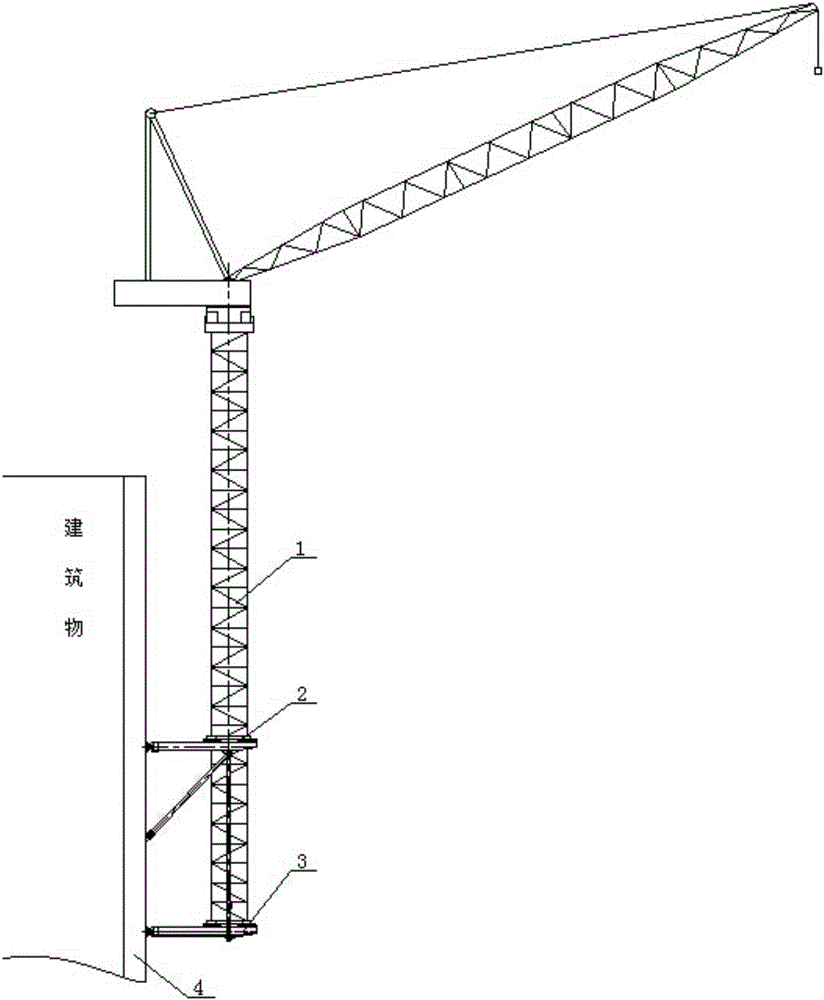

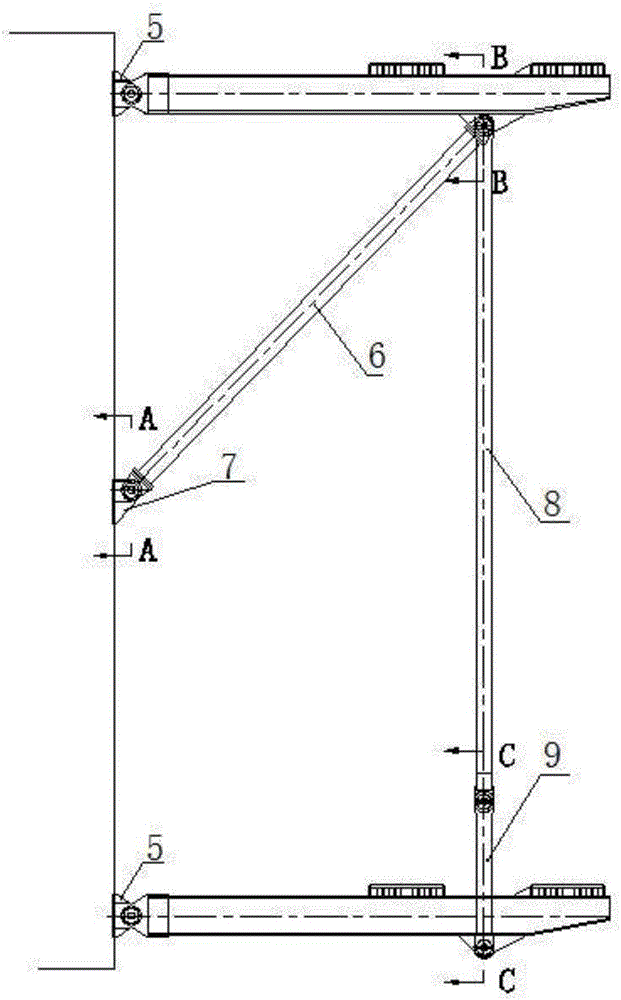

[0043] Embodiment 1: as figure 1 , figure 2 , Image 6 As shown, the present invention is a support system for an asymmetric frame series externally suspended tower crane, which includes two sets of support structures 3, two symmetrical diagonal braces 6 and two vertical pull rods 8, the two sets of supports The protective structure is arranged parallel to the upper and lower sides, adopts series support, and one end is respectively connected to the wall 4, and the upper and lower two sets of support structures 3 near the other end are symmetrically connected with two vertical tie rods 8 to form a frame structure, and the two diagonal braces 6 are symmetrical One end is connected to the upper support structure 3, and the other end is connected to the wall 4 between the upper and lower support structures 3. The position of the support point can be adjusted according to the needs of the building structure or the tower crane.

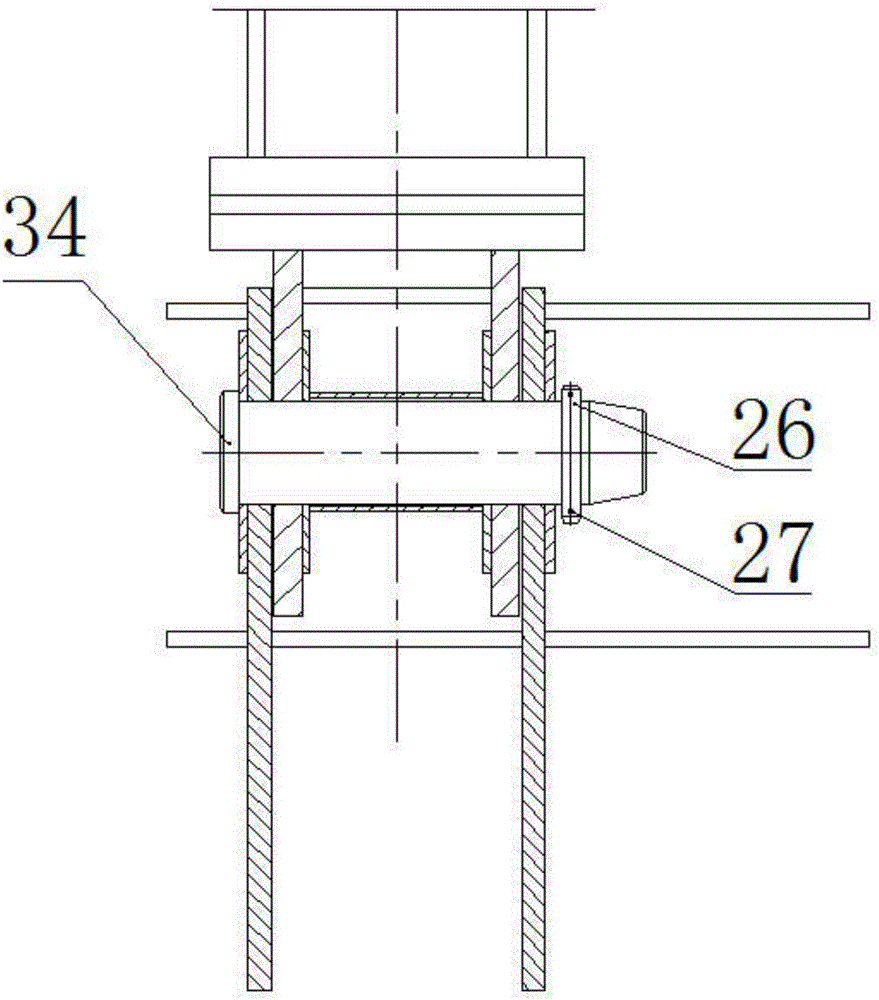

[0044] like Image 6 As shown, the upper and low...

Embodiment 2

[0055] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in this embodiment, the third strut 19 is not provided when the building wall does not have enough supporting space and the third strut 19 is not allowed to be connected. Support requirements can also be met.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com