A kind of preparation technology of large-diameter variable-angle pvc pipe

A PVC pipe material and preparation technology, applied to tubular objects, other household appliances, household appliances, etc., can solve the problems of high hardness, increased cost, and poor flexibility of PVC pipes, and achieve simple processing and manufacturing processes, increase production costs, and use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

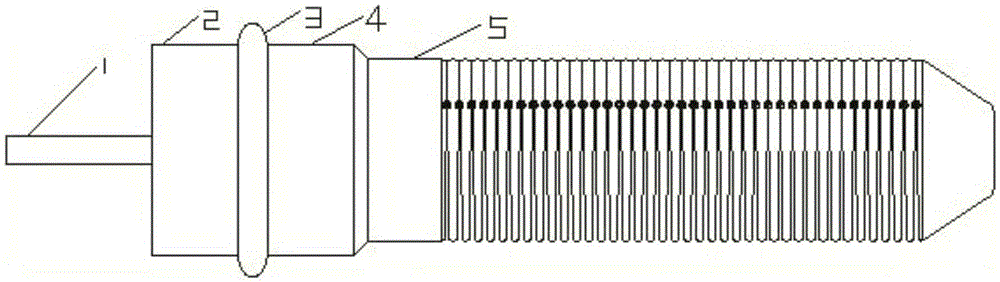

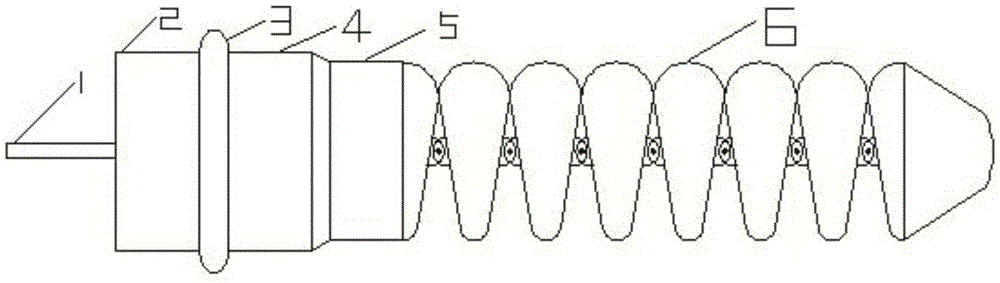

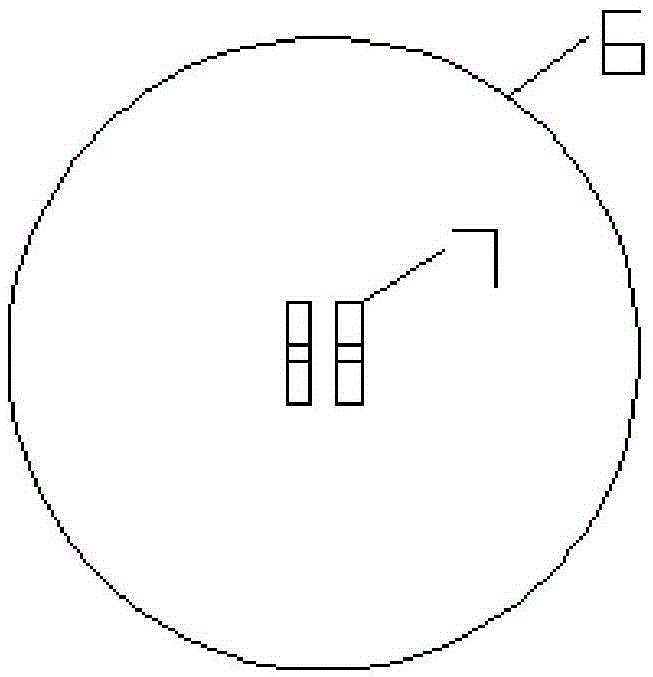

Image

Examples

Embodiment 1

[0050] A process for preparing variable-angle PVC pipes with a caliber of 630mm, the process steps are as follows:

[0051] (1) Mixing: Take 100kg SG-4 PVC resin powder, 0.4kg calcium zinc stabilizer, 2kg rubber toughening agent, 2kg inorganic rigid particle calcium carbonate, 0.5kgACR-201 processing aid, 0.6kg polyethylene wax ( PE wax), 0.5kg of stearic acid, 0.05kg of hindered phenolic antioxidant BHT, 0.03kg of rutile titanium dioxide and 1kg of precipitated barium sulfate were put into a high-speed mixer for hot mixing, and the mixture was heated to 90°C. After reaching the temperature, it is cold-mixed by a high-speed mixer, and the mixed material is cold-mixed to 25°C, and then put into a drying silo to obtain a mixed material;

[0052] (2) Extrusion: Put the mixed material obtained in step (1) into a conical twin-screw extruder to extrude the pipe. Head temperature: 170°C; host speed: 10 rpm, feeding speed: 10 rpm;

[0053] (3) Cooling and shaping: The pipe extruded ...

Embodiment 2

[0062] A process for preparing variable-angle PVC pipes with a diameter of 800mm, the process steps are as follows:

[0063] (1) Mixing: 100kg SG-5 PVC resin powder, 4kg lead salt stabilizer, 6kg thermoplastic elastomer toughener, 8kg organic rigid particle acrylonitrile-styrene copolymer (AS), 3kgACR-401 processing aid Agent, 1.5kg paraffin wax, 1kg calcium stearate, 101 parts of 0.5kg hindered phenolic antioxidant, 3kg anatase titanium dioxide and 5kg calcium carbonate were put into a high-speed mixer and heated to 120 °C, after reaching the temperature, it is cold-mixed by a high-speed mixer, and the mixed material is cold-mixed to 45 °C, and then put into the drying silo to obtain the mixed material;

[0064] (2) Extrusion: Put the mixed material obtained in step (1) into a conical twin-screw extruder to extrude the pipe. Head temperature: 220°C; host speed: 90 rpm, feeding speed: 90 rpm;

[0065] (3) Cooling and shaping: The pipe extruded in step (2) is shaped according...

Embodiment 3

[0074] A process for preparing variable-angle PVC pipes with a caliber of 700mm, the process steps are as described in Example 1, the difference is: step (1) mixing: take 100kg SG-5 type PVC resin powder, 2kg organotin stabilizer , 3kg thermoplastic elastomer toughener, 5kg organic rigid particle acrylonitrile-styrene copolymer (AS), 1kgACR-401 processing aid, 1kg microcrystalline wax, 1kg calcium stearate, 0.5kg hindered phenolic anti Oxygen agent 1010, 1kg anatase titanium dioxide and 2kg calcium carbonate were put into a high-speed mixer for hot mixing, and the mixture was hot-mixed to 90°C. Put it into the drying silo after 45°C to get the mixed material;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com