Bendable planer tool device

A planer and bending technology, which is applied in the field of bendable planer devices, can solve problems such as inability to realize bending, cannot effectively realize bending, and affect operation efficiency, and achieves the effect of improving efficiency, simple structure and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

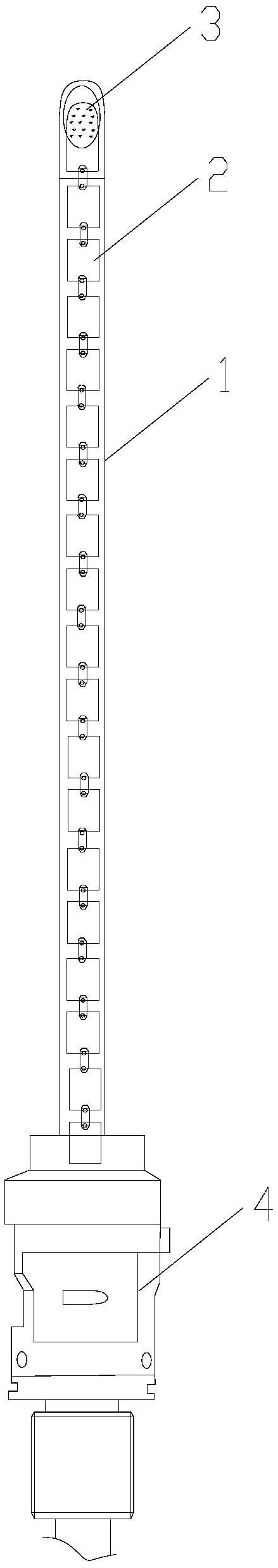

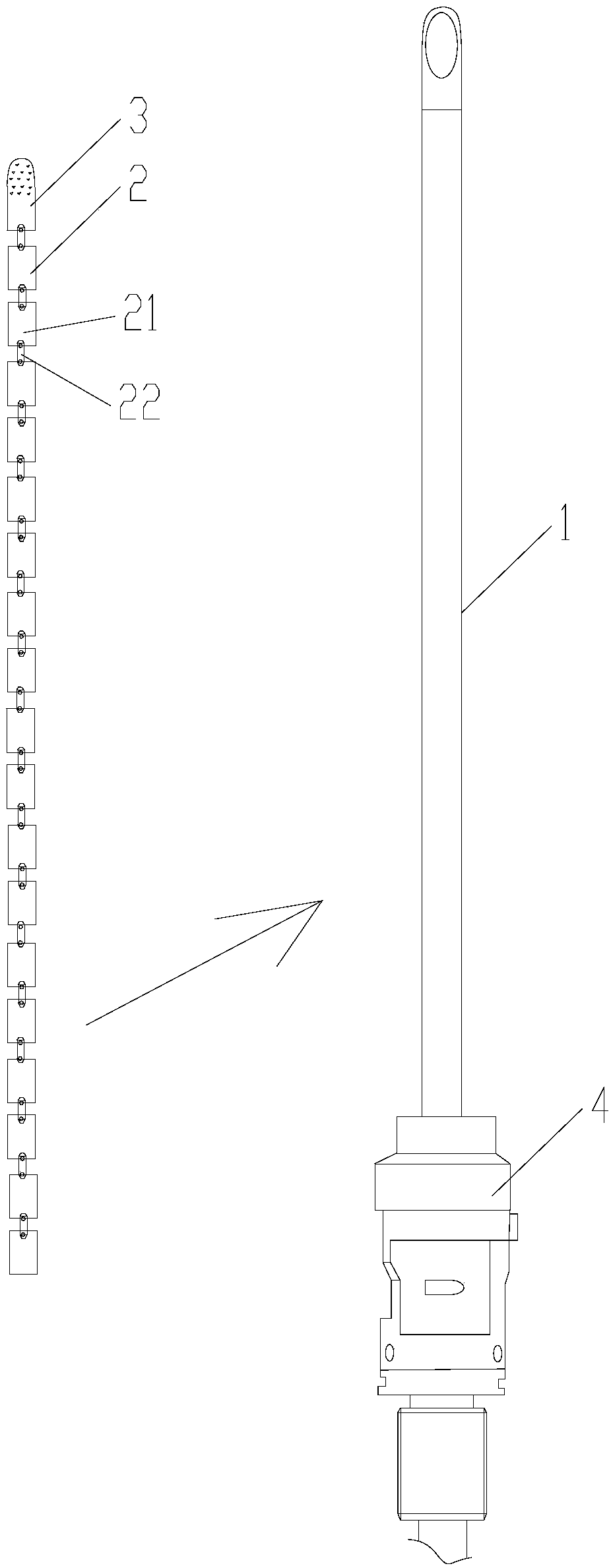

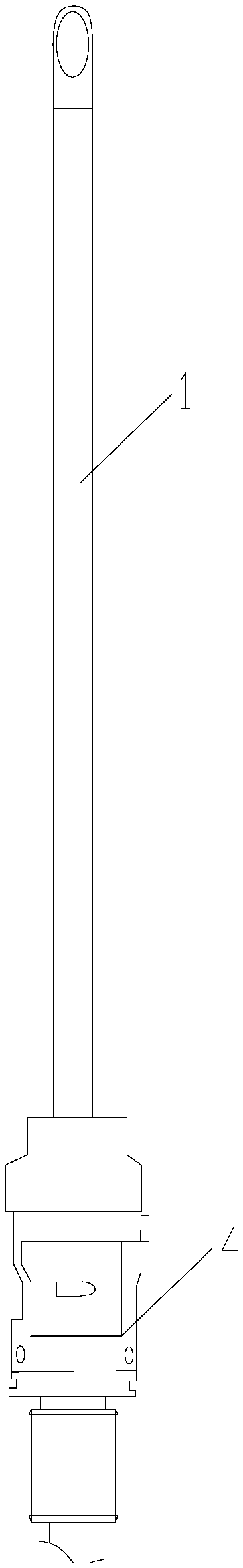

[0043] see figure 1 , figure 2 , image 3 , Figure 4 (as well as Figure 5 , Image 6 , Figure 7 with Figure 8 ), Embodiment 1 of the present invention provides a kind of bendable planer device, comprises outer sheath pipe 1 (see also image 3 as well as Figure 7 ), a rotatable inner tube 2 and a planer head 3 arranged inside the outer sheath tube 1;

[0044] Wherein, one end of the rotatable inner tube 2 is used to connect a rotating drive device (not shown in the figure), and the other end of the rotatable inner tube 2 is connected to the planer head 3;

[0045] The tail end of the outer sheath tube 1 is a metal tube, and the front end is a memory alloy tube; and the rotatable inner tube 2 includes a plurality of single-section inner tube units 21 and hinged connectors 22; The single-segment inner tube units 21 are connected sequentially, the single-segment inner tube unit 21 at the end is specifically connected to the planer head 3, and any two adjacent single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com