Patents

Literature

70results about How to "No increase in production cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of acidic extractant complexing extraction separation rare-earth element

InactiveCN101182597ALess investmentReduce pollutionProcess efficiency improvementSkin complexionRare-earth element

The invention relates to a method for complexing, extracting and separating the rare earth element with an acid phosphate extraction agent; the point is that rare earth chloride solution is added with citric acid or salt citrate to form rare earth chloride-hydrochloric acid-citric acid mixing solution as the water phase and the P204 or P205 acid phosphate extraction agent for extraction and separation; diluted coal oil is taken as the organic phase for extraction and separation; the rare earth element is separated through processes of extraction, washing and reverse extraction in an extraction groove; the extraction residual liquid which contains the citric acid is returned for recycling. The invention is characterized in that with the complexion action of the citric acid and the rare earth element, the separation effect of the acid phosphate extraction agent on the rare earth element is enhanced and especially the rare earth element in the high-consistency rare earth solution, the REO of which equals to 200 to 300g / l can be separated; at the same time, the acid phosphate extraction agent also has comparatively high capability and effect for extracting the rare earth element without saponification process. The invention needs a small amount of investment and the production cost is low; moreover, according to the method, the environmental pollution is reduced.

Owner:NORTHEASTERN UNIV LIAONING

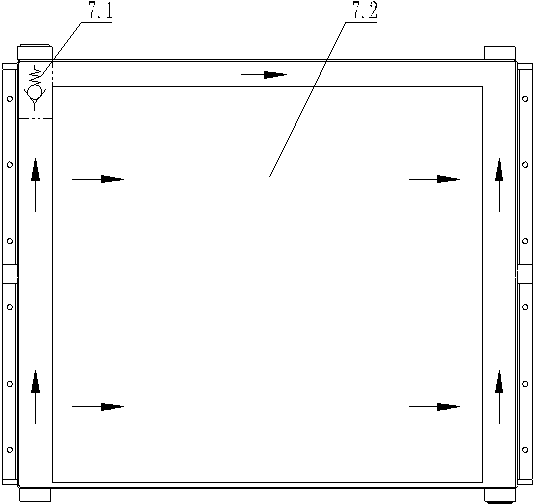

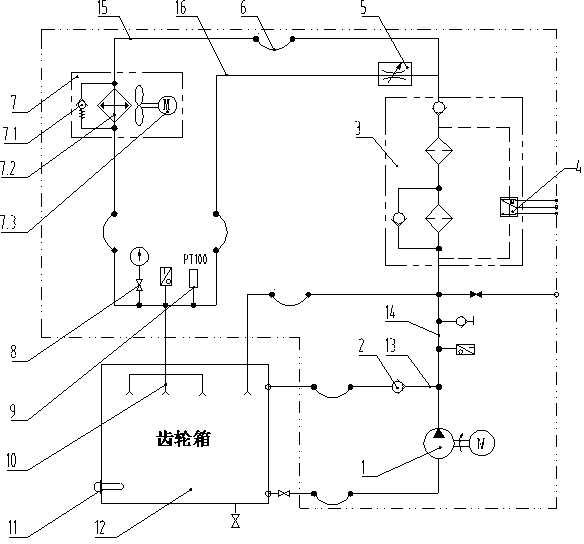

Cooling lubricating system of step-up gear box of wind generating set and low-temperature starting method thereof

ActiveCN104696496AResolve downtimeNo added complexityEngine fuctionsGear lubrication/coolingThermodynamicsEngineering

The invention refers to the technical field of wind power and particularly relates to a lubricant cooler, a cooling lubricating system of a step-up gear box, a wind power unit and a low-temperature starting method of the wind power unit. The lubricant cooler of the invention comprises a radiating plate and a unidirectional valve arranged on a lubricant conveying pipeline; the radiating plate and the unidirectional valve are arranged in parallel, and the unidirectional valve and the lubricant conveying pipeline interconnected with the unidirectional valve are integrated on the radiating plate. The lubricant cooler of the invention can solve the problem that the wind power unit of the cooling lubricating system of step-up gear box is shutdown for failure for the lubricant blocks the radiating plate. The cooling lubricating system of the step-up gear box is simple in structure. The wind power unit can be effectively started under low temperature. The low-temperature starting method of the wind power unit can smoothly start the wind power unit under the low-temperature environment.

Owner:CSIC CHONGQING HAIZHUANG WINDPOWER EQUIP

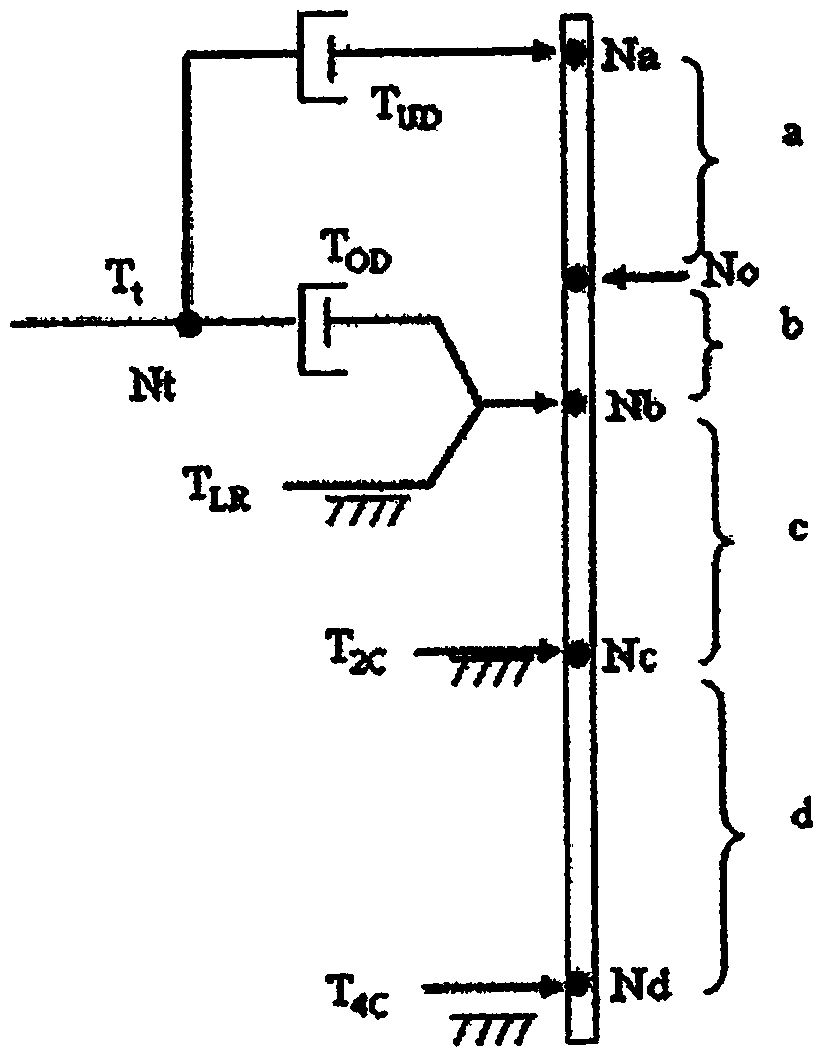

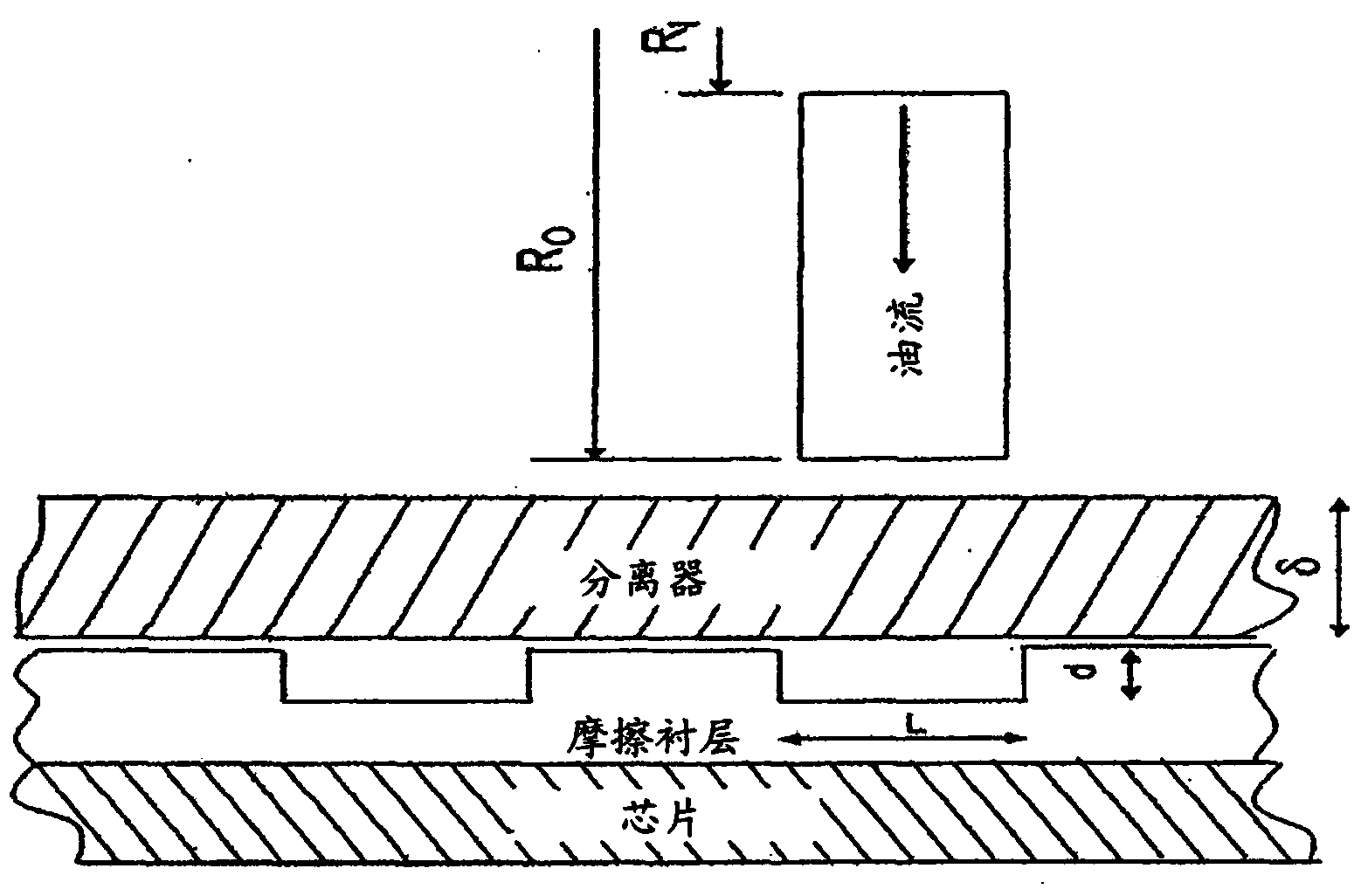

Method for determining wet clutch temperature

ActiveCN103459876AAvoid Overheating FailuresReduce Warranty CostsClutchesVaporizationThreshold temperature

A method (500) for determining clutch temperature. The method provides an accurate real-time clutch temperature that can be used to improve shift quality and protect against failure due to clutch overheating (510). A counter is incremented (506) every time the clutch exceeds a threshold temperature (504) to track cumulative high temperature conditions. Determining the clutch temperatures (502) includes taking account of heat generation, clutch cooling by transmission oil flow from a groove when the clutch is engaged, clutch cooling by open transmission oil flow when the clutch is disengaged, oil vaporization, and heat conduction.

Owner:CHRYSLER GROUP LLC

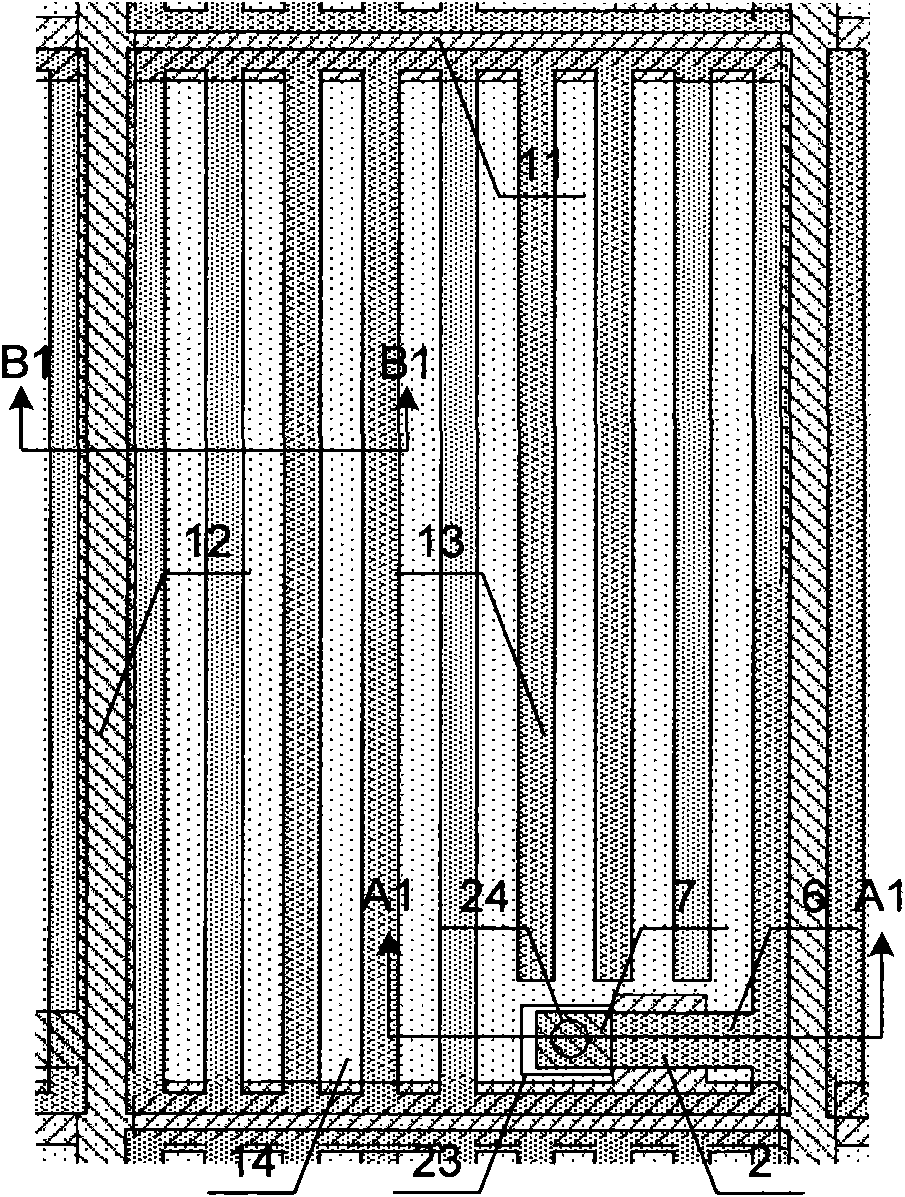

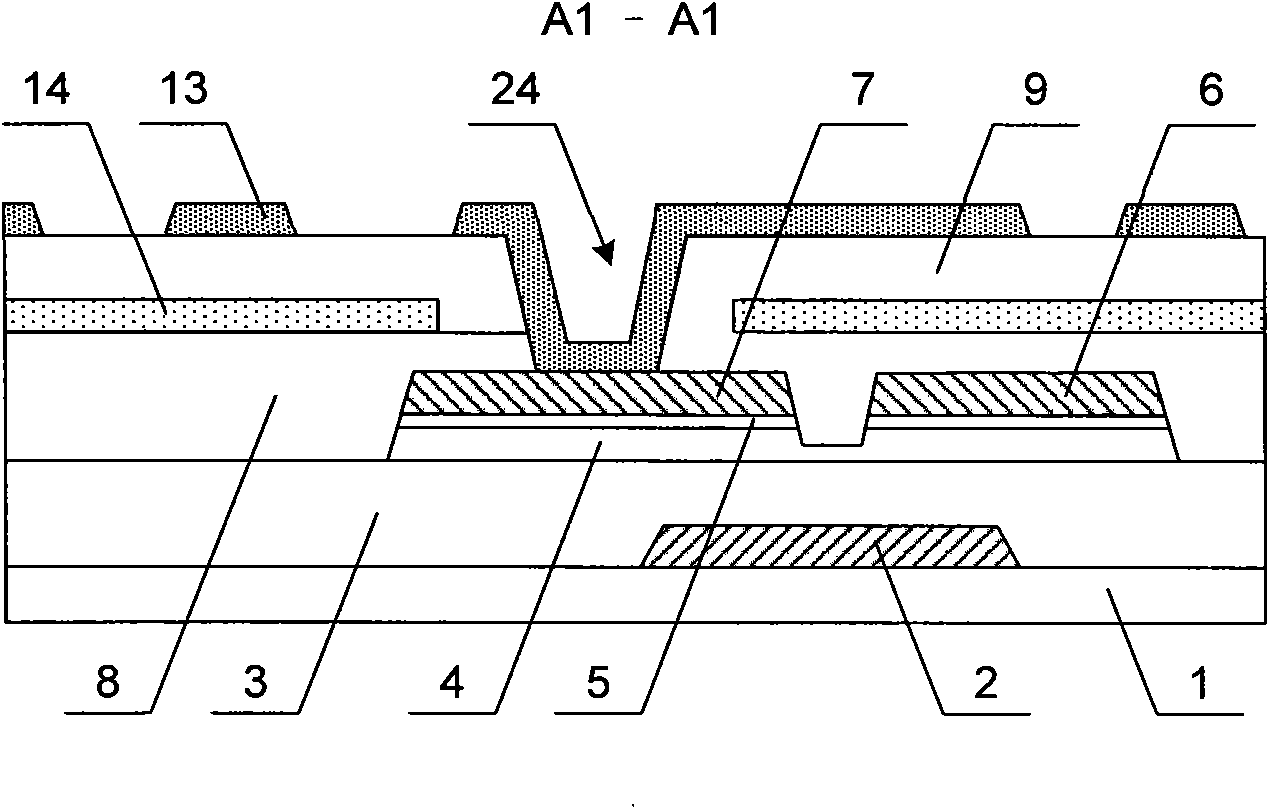

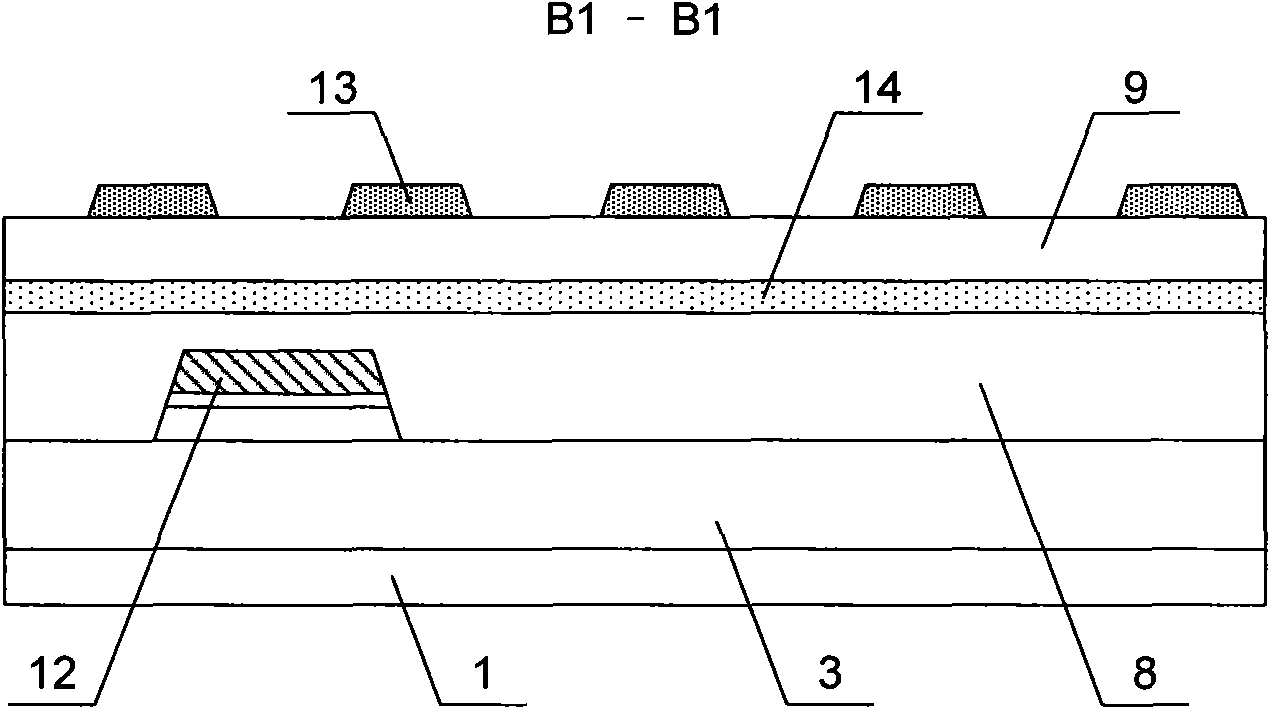

Thin film transistor liquid crystal display (TFT-LCD) array substrate and manufacturing method thereof

ActiveCN102156369AIncrease the areaImprove the efficiency of driving liquid crystalSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringThin-film-transistor liquid-crystal display

The invention relates to a thin film transistor liquid crystal display (TFT-LCD) array substrate and a manufacturing method thereof. The array substrate comprises grid lines and data lines which define a pixel region, wherein a TFT, common electrodes and pixel electrodes of electrode strip structure are formed in the pixel region; the common electrodes are formed on a second insulating layer covering the data lines; and the pixel electrodes are formed on a third insulating layer covering the common electrodes. The array substrate and the manufacturing method have the following beneficial effects: by forming the common electrodes on the second insulating layer covering the data lines, forming the pixel electrodes of electrode strip structure on the third insulating layer covering the common electrodes and driving all the liquid crystals in the regions between the edges of the pixel electrodes and the edges of the data lines with a regular electric field, the efficiency of driving the liquid crystals is improved and the region becomes a display region, thus farthest increasing the area of the display region and effectively improving the aperture opening ratio.

Owner:BOE TECH GRP CO LTD +1

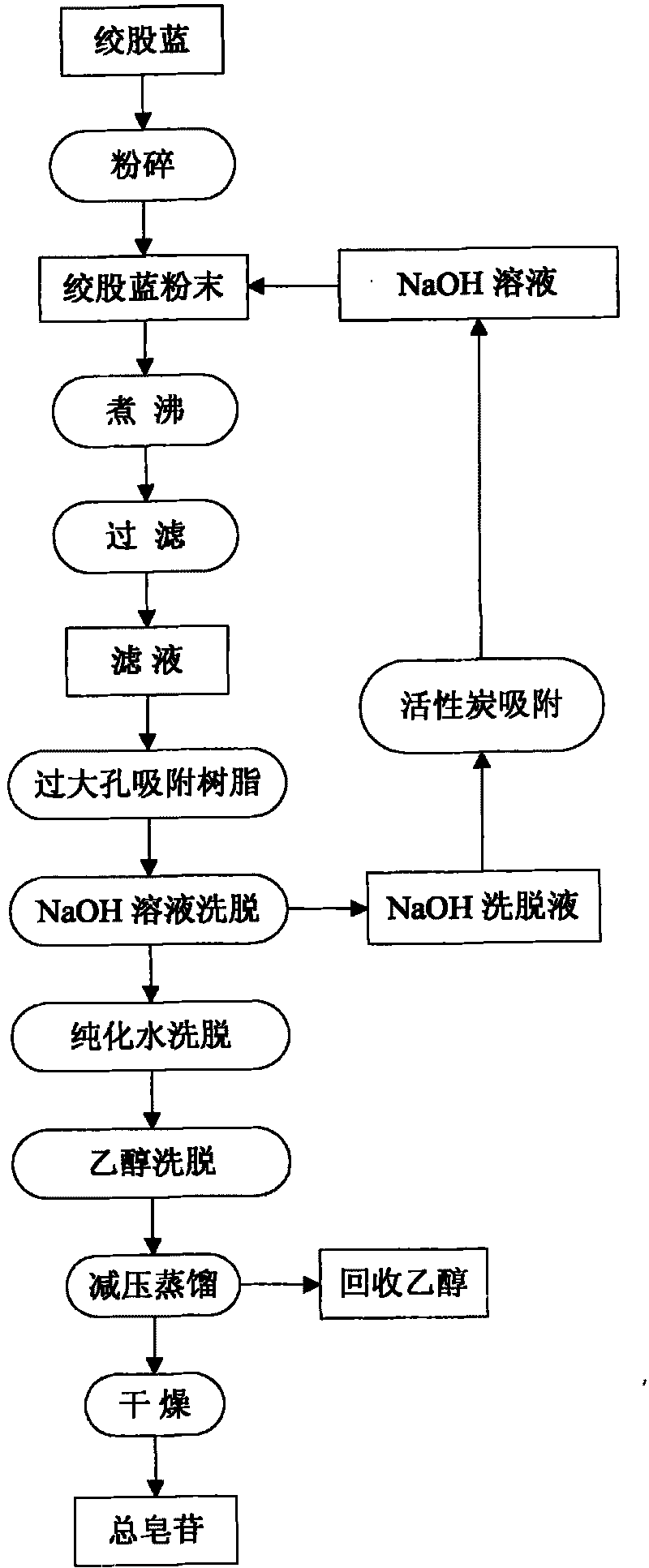

Method for extracting gypenosides

InactiveCN101732398ALow costImprove solubilityMetabolism disorderCardiovascular disorderAqueous solutionPurified water

The invention discloses a method for extracting gypenosides, which comprises the following steps: (1) pulverizing fiveleaf gynostemma herb to obtain fiveleaf gynostemma herb powders; (2) adding the fiveleaf gynostemma herb powders obtained in the step (1) into aqueous solution of NaOH for boiling, filtering, and taking filtrate; (3) adsorbing the filtrate obtained in the step (2) by macroporous absorption resin, eluting the macroporous absorption resin by the aqueous solution of NaOH till colorlessness, collecting NaOH eluant, washing the NaOH eluant by purified water till neutrality, finally desorbing the NaOH eluant by ethanol, and collecting ethanol stripping liquid; (4) adsorbing the NaOH eluant by active carbon, and circulating the NaOH eluant in the step (2) after pigment removal; and (5) distilling ethanol liquid obtained in the step (4) under reduced pressure, reclaiming the ethanol, and drying solid to obtain the gypenosides. The method has the advantages of low cost, high efficiency, no pollution and high product purity.

Owner:陕西太极华青科技有限公司

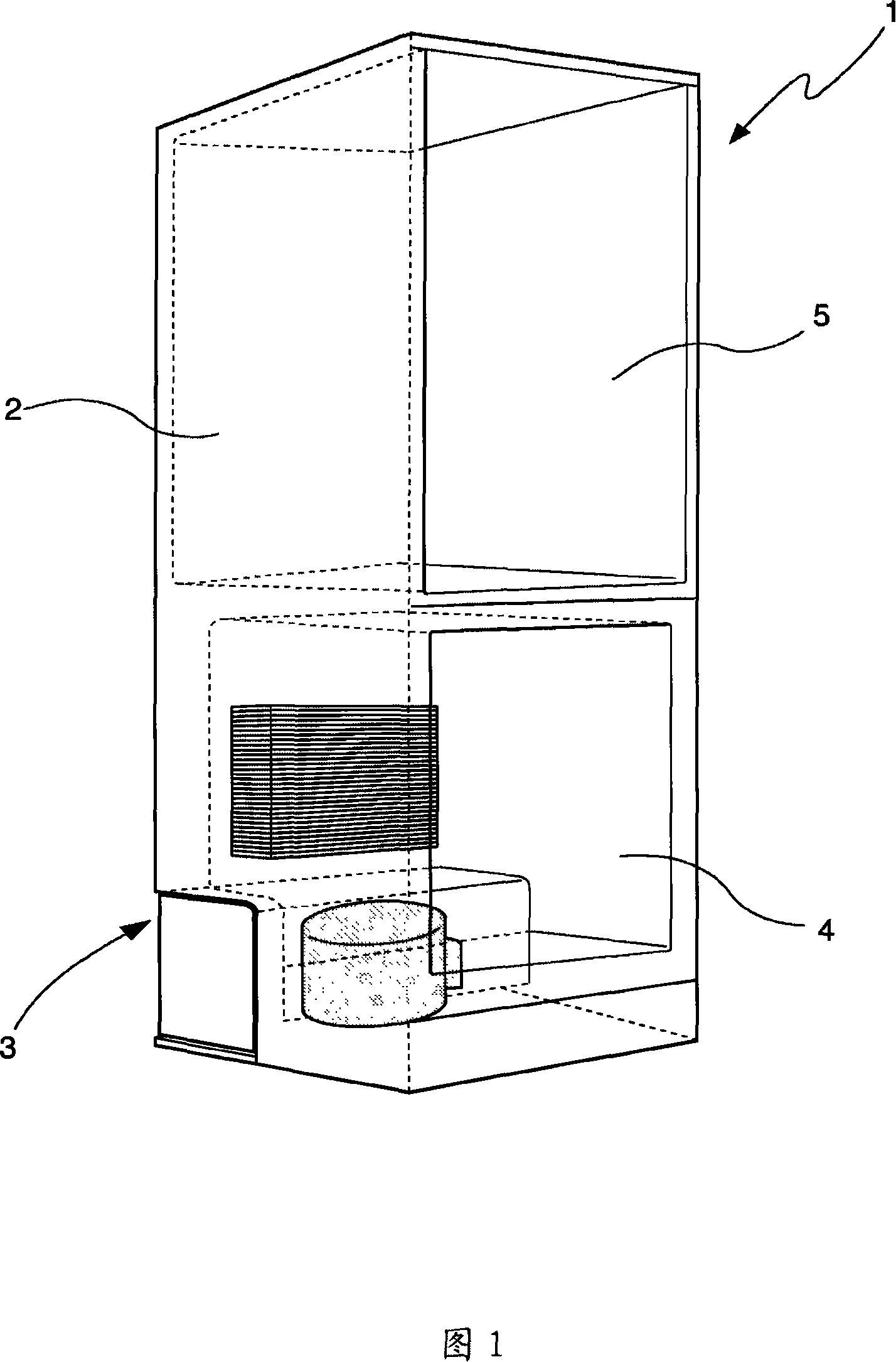

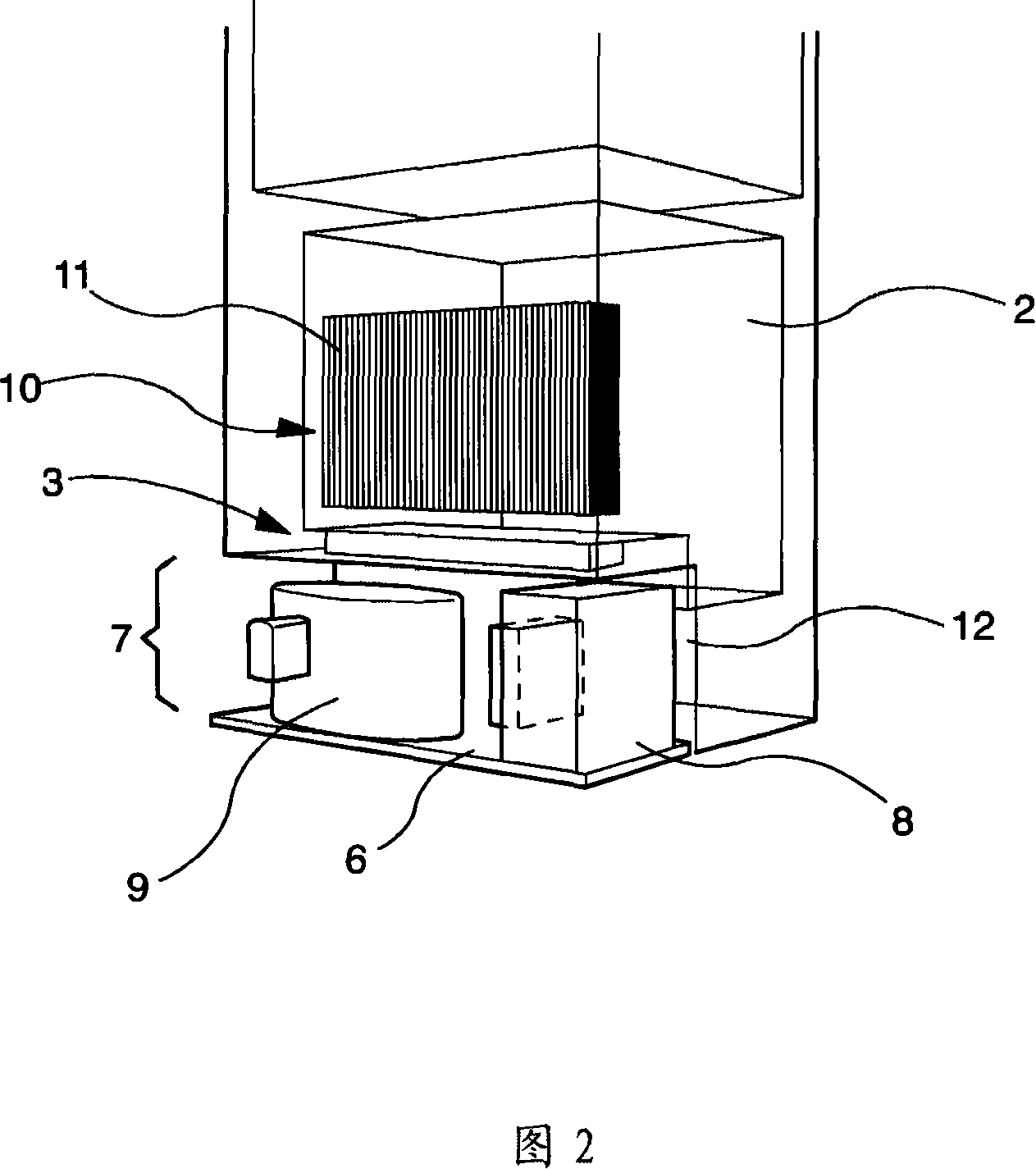

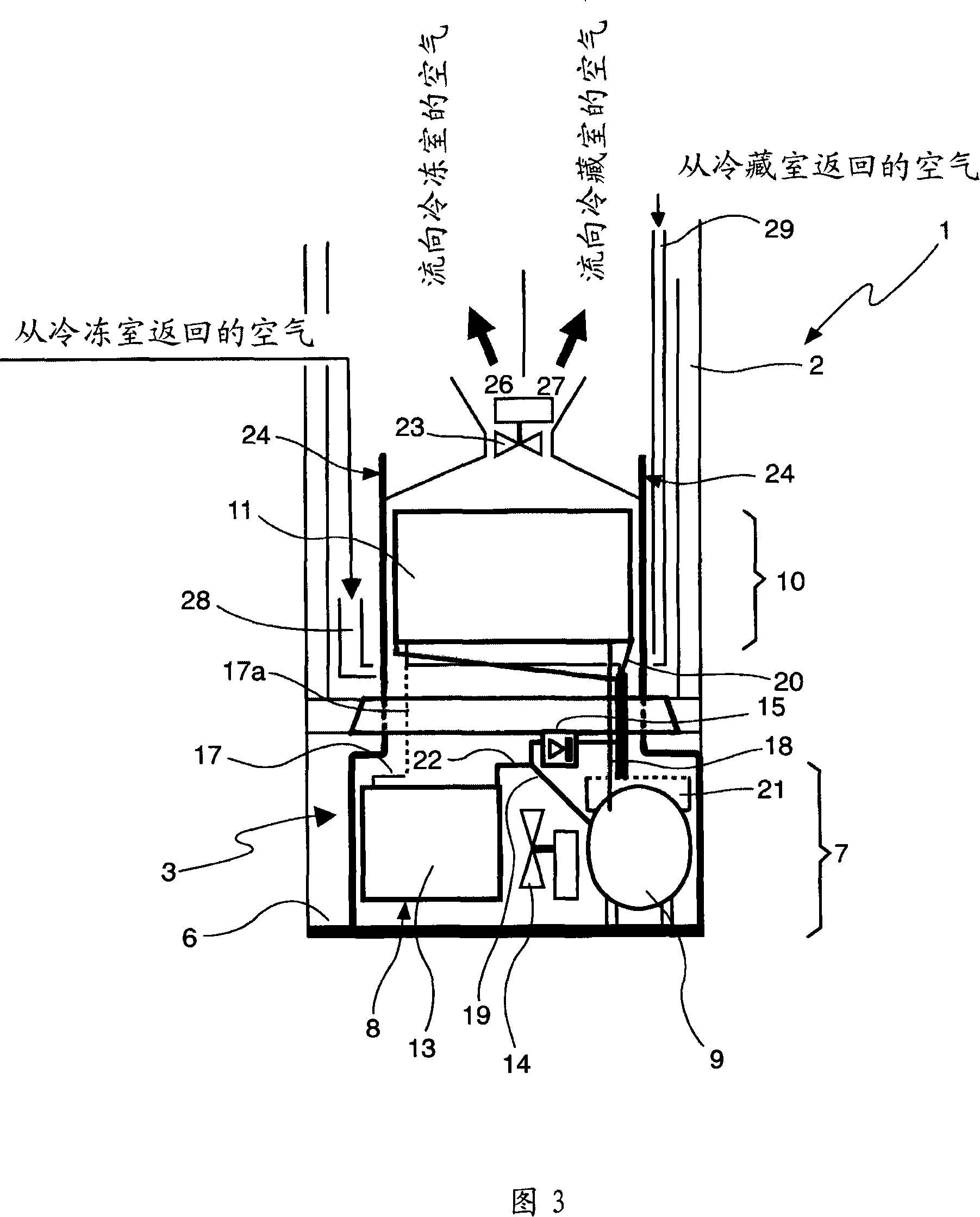

Modular refrigeration unit and process for assembling a modular refrigeration unit to a cabinet of a refrigeration appliance

InactiveCN101103235AOvercome limitationsEasy to installLighting and heating apparatusRefrigeration devicesEngineeringRefrigeration

The present invention relates to a modular refrigeration unit for a refrigeration appliance, and to a process for assembling the modular refrigeration unit to a cabinet of a refrigeration appliance. A modular refrigeration unit (3) includes a base plate (6) supporting a condensing assembly (7), which comprises condensing means (8) and a compressor (9), and an evaporating assembly (10) comprising an evaporator (11); the condensing assembly and the evaporating assembly are operatively interconnected. The evaporating assembly (10) is arranged, in use, vertically spaced apart and above the compressor (9); the evaporating assembly (10) is supported by support means (24) vertically extending from the base plate (6); insulating means (16) separate the evaporating assembly (10) from the condensing assembly (7, 107).

Owner:ELECTROLUX HOME PROD CORP NV

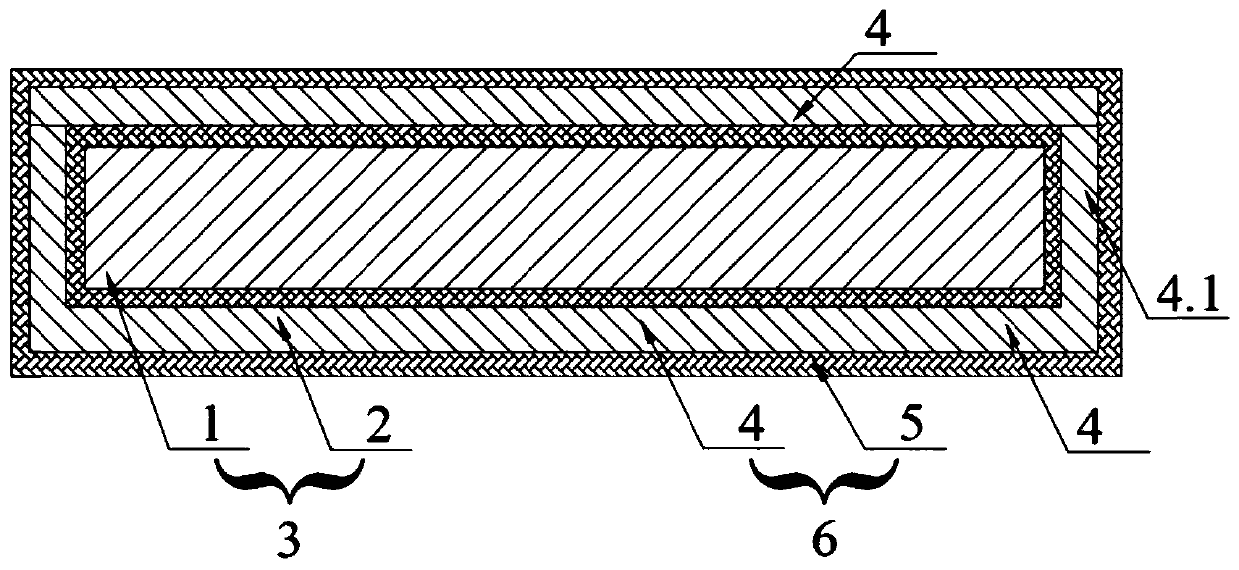

Vacuum insulation board with no fear of surface damage and processing technology

ActiveCN110792879ASimple structureGood insulation performanceCovering/liningsThermal insulationGlass fiberEngineering

The invention discloses a vacuum insulation board with no fear of surface damage and a processing technology thereof. The vacuum insulation board comprises an inner vacuum structural layer and at least one outer vacuum structural layer wrapped outside the inner vacuum structural layer, wherein the inner vacuum structure layer is composed of an inner core plate and a high vacuum barrier film wrapped outside the inner core plate, the inner core plate inner vacuum structure layer is composed of the inner core plate and the high vacuum barrier film wrapped outside the inner core plate, the inner core plate is prepared from a material such as glass fibers through carding hot pressing or dispersion wet method and a vacuum process, the inner core plate and a getter material are placed into the high vacuum barrier film to be made into the inner vacuum structure layer through high vacuum heat sealing equipment, the outer vacuum structure layer is composed of the inner vacuum structure, an outercore plate and a high-vacuum barrier film wrapped outside the outer core plate, and the outer core plate is made of glass fiber and other materials through wet-process mixed dispersion through a vacuum forming process. The vacuum insulation board has the characteristics of being good in heat preservation effect, safe, light, simple in construction, and capable of opening holes and the like, and after the surface is damaged, no drum, no expansion, no water absorption, and good retention and heat insulation performance are reserved.

Owner:安徽百特新材料科技有限公司

Hard-face overlaying welding material and use thereof

ActiveCN101439445AAvoid phase changeUniform tissueFurnace typesHeat treatment process controlChemical compositionWear resistant

The invention discloses an overlaying welding alloy material which can resist abrasion and corrosion and can be moulded without crack, and usage thereof. Counted by weight percentage, the welding alloy material comprises the components as follows: 0.4-0.6 percent of C, 0.6-1.0 percent of Si, 1.5-1.8 percent of Mn, 0.8-1.2 percent of Mo, 14-16 percent of Cr, 0.6-1.0 percent of W, 0.3-0.5 percent of Nb, 0.05-0.1 percent of V, 0.05-0.1 percent of rare earth, not more than 0.035 percent of S, not more than 0.035 percent of P and the balance of Fe, wherein, the amount of the components is 100%. The welding process matching the material comprises that the heating temperature is 180-230 DEG C; the interlayer temperature is 250-300 DEG C and the backfiring temperature is 550-650 DEG C. The invention is simple in process and adds no cost. The alloy is overlaying welded on the surface of a work piece so that the anti-abrasion capability thereof is the same as the capability of high-chromium cast iron welding material. Meanwhile, no crack forms in the moulding process, thereby enhancing the anticorrosion capability; therefore, the comprehensive performance of the material is better than that of high-chromium cast iron, so as to prolong service life of the work piece. Take for instance, the comprehensive performance of a rotor of an internal mixer is more than 1.5 times of an original one. Meanwhile, the surface is moulded without crack so that the material can also be used as hard alloy of the transition layer during manufacturing process of a super wear-resistant piece.

Owner:YIYANG RUBBER PLASTICS MACHINERY GROUP

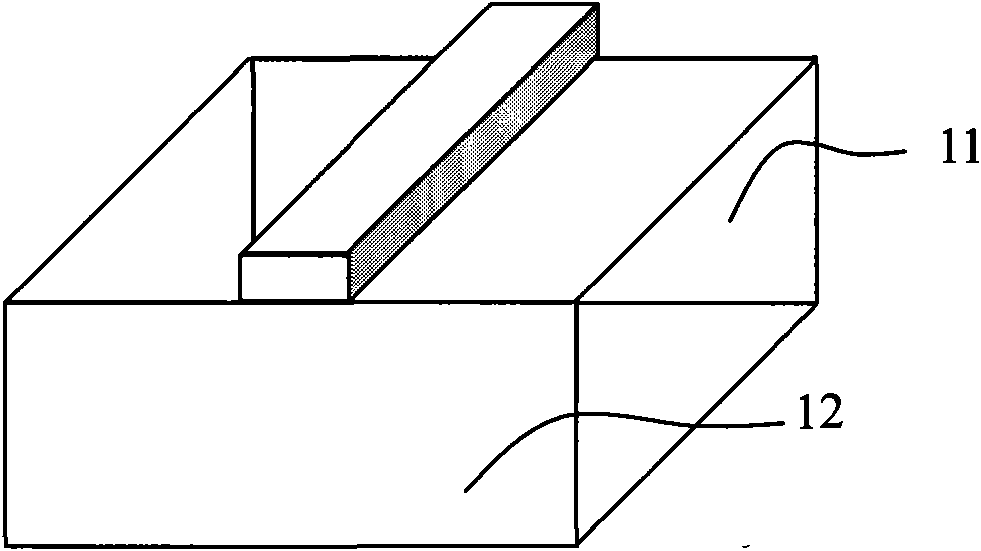

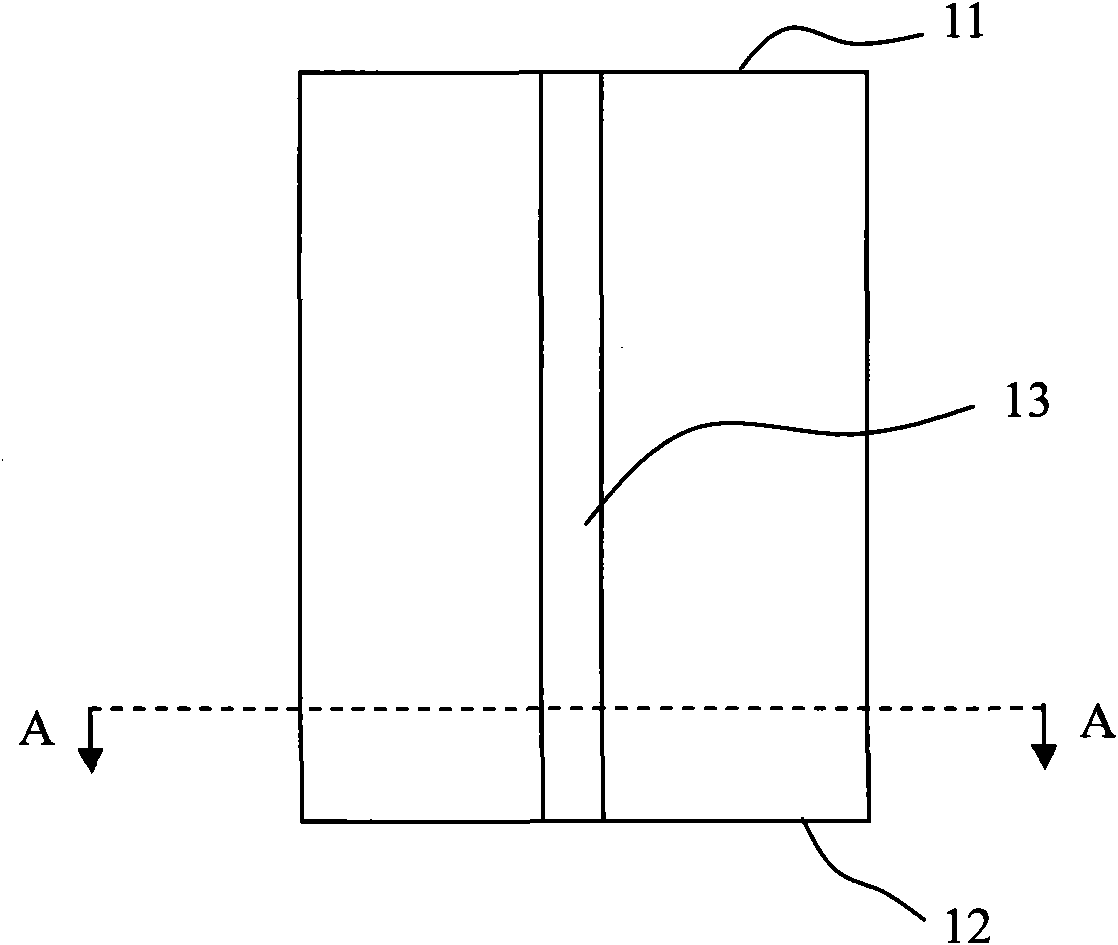

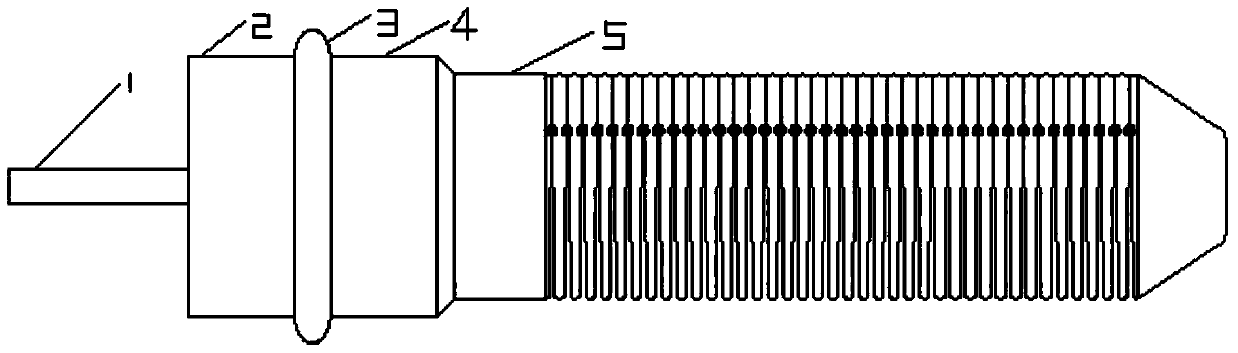

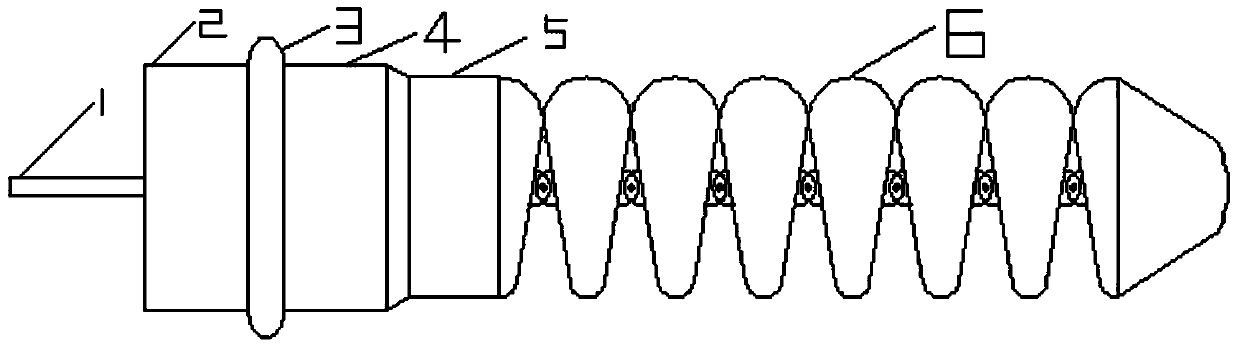

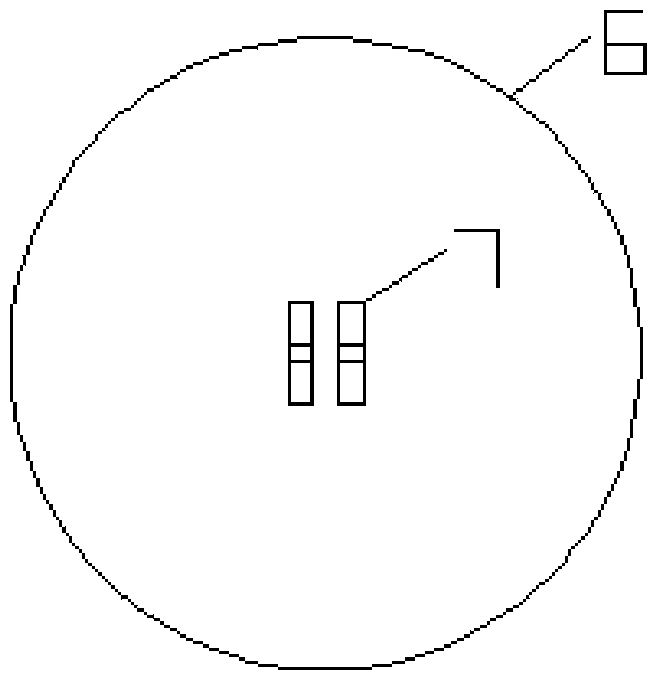

Micro semiconductor laser diode capable of realizing high power single-mode output and manufacturing method thereof

InactiveCN101916963AIncreased peak optical output powerSmall sizeLaser optical resonator constructionLaser active region structureResonant cavityHigh density

The invention provides a micro semiconductor laser diode capable of realizing high power single-mode output and a manufacturing method thereof and particularly discloses a semiconductor laser diode with a non-rectangular resonant cavity and a manufacturing method thereof. The parts, near the vertical light extraction end faces, at the two ends of the resonant cavity are of rectangular single-channel waveguide structures. The middle part of the resonant cavity comprises the waveguide structure with at least a channel. The light peak output power of the laser diode is increased under the condition of keeping the total straight length of the resonant cavity and the volume of the laser diode invariant, so that the chip product rates on the substrates with the same size are increased, thus lowering the product cost and providing a solution for the special application of high-density integrated circuits of light and ultra-small integration space but with high light power.

Owner:厉巧云 +1

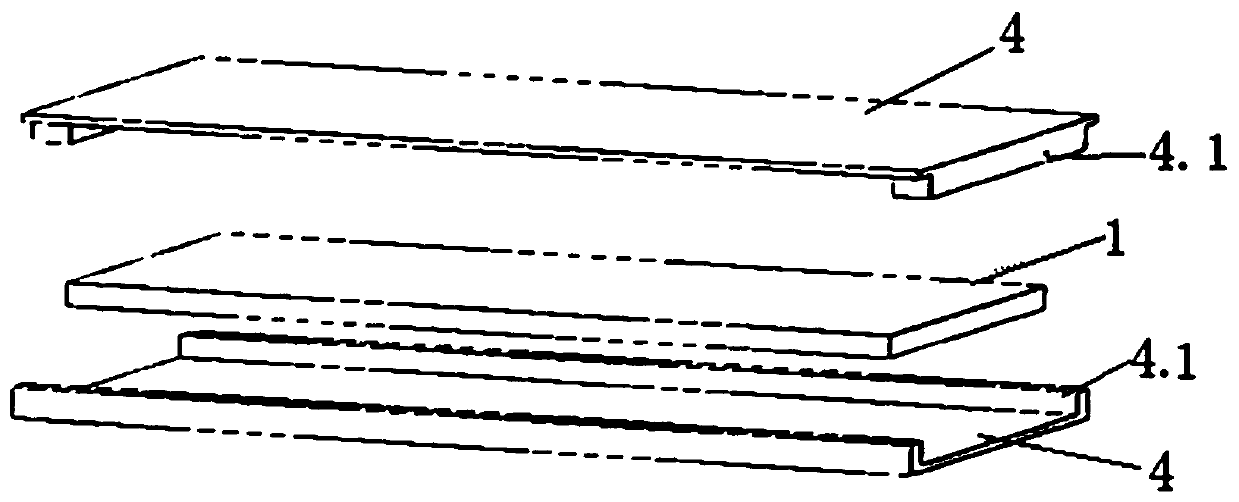

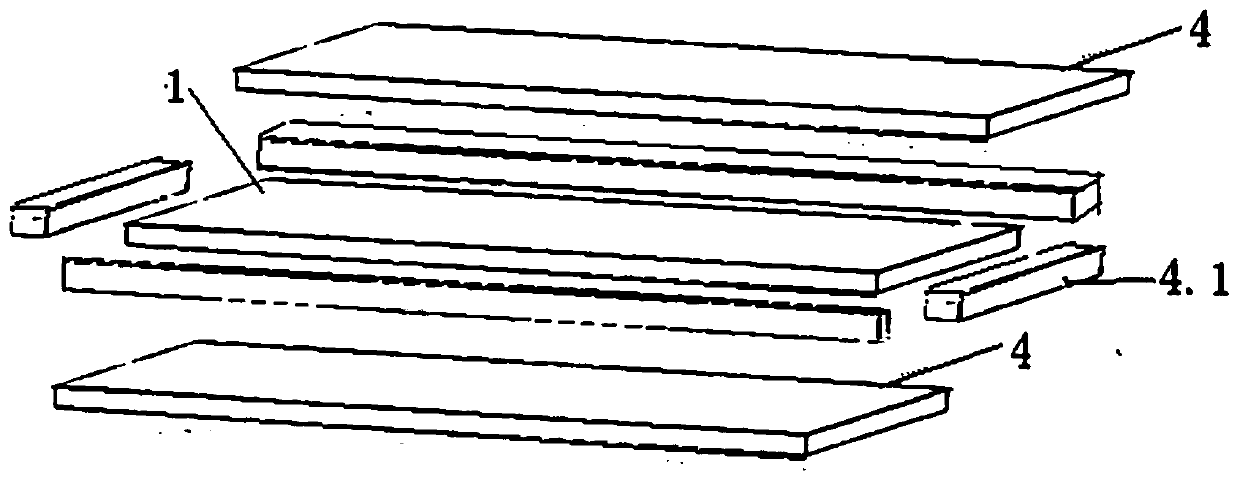

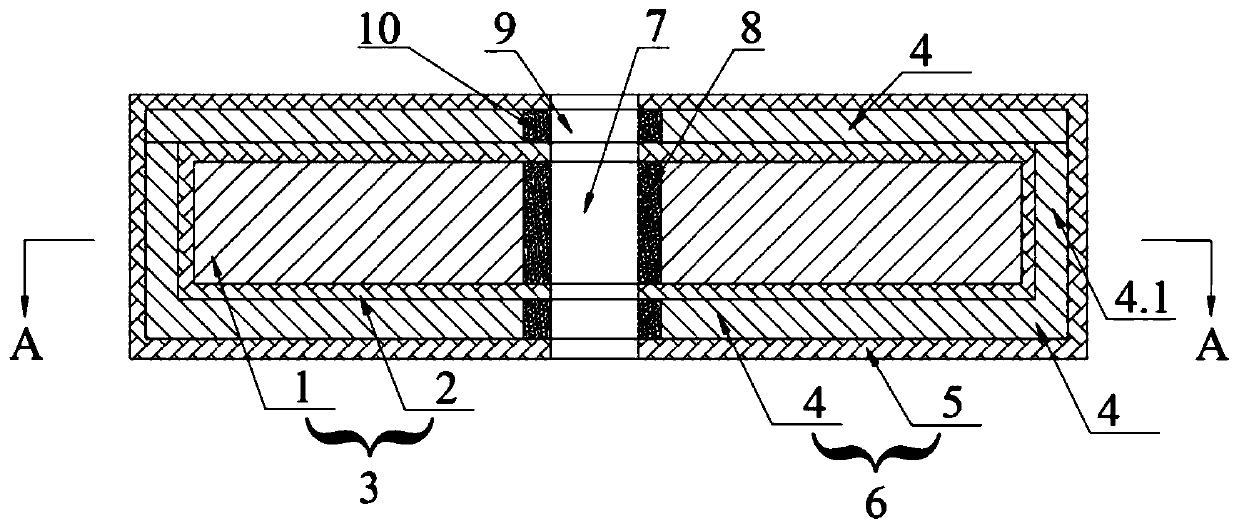

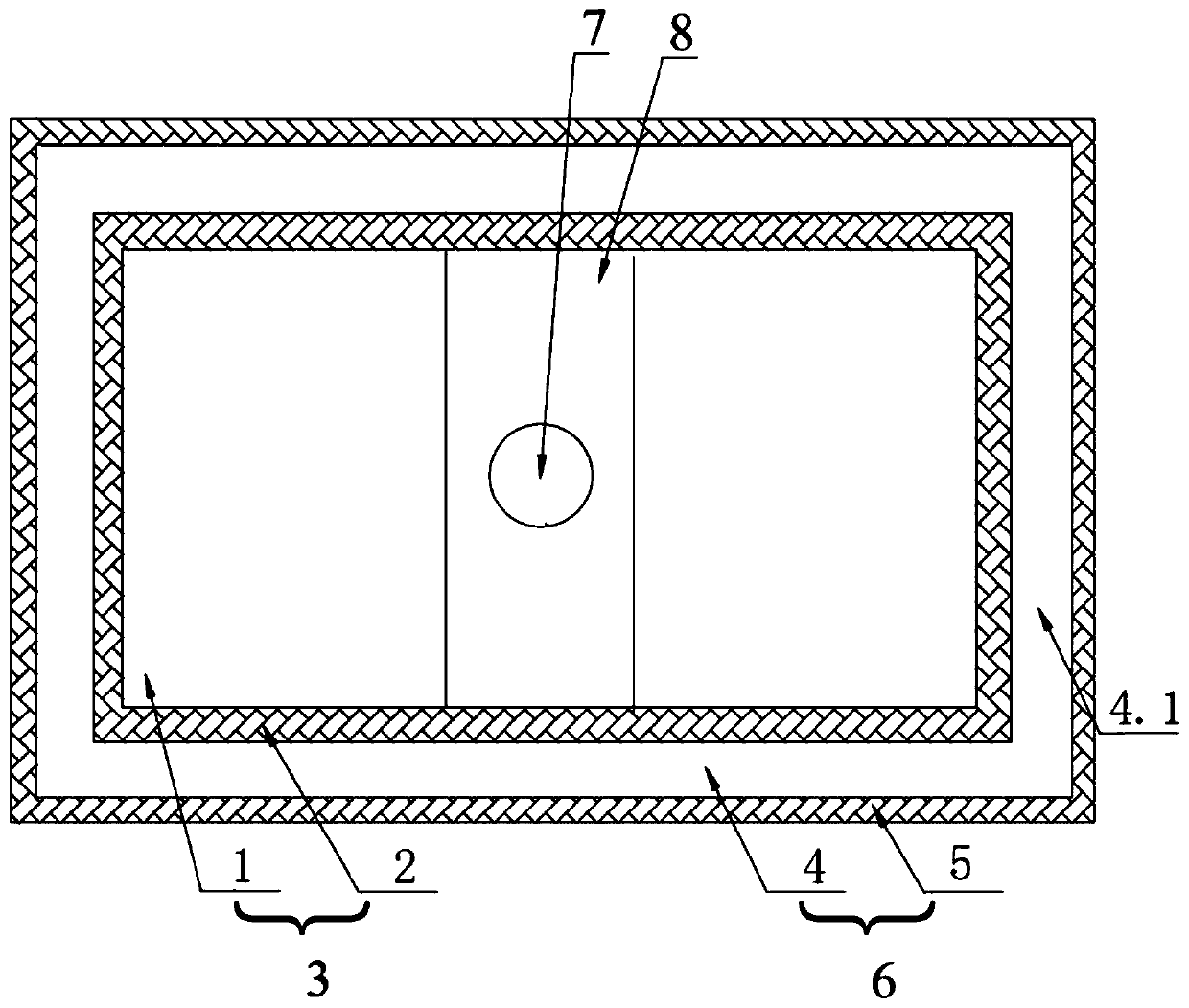

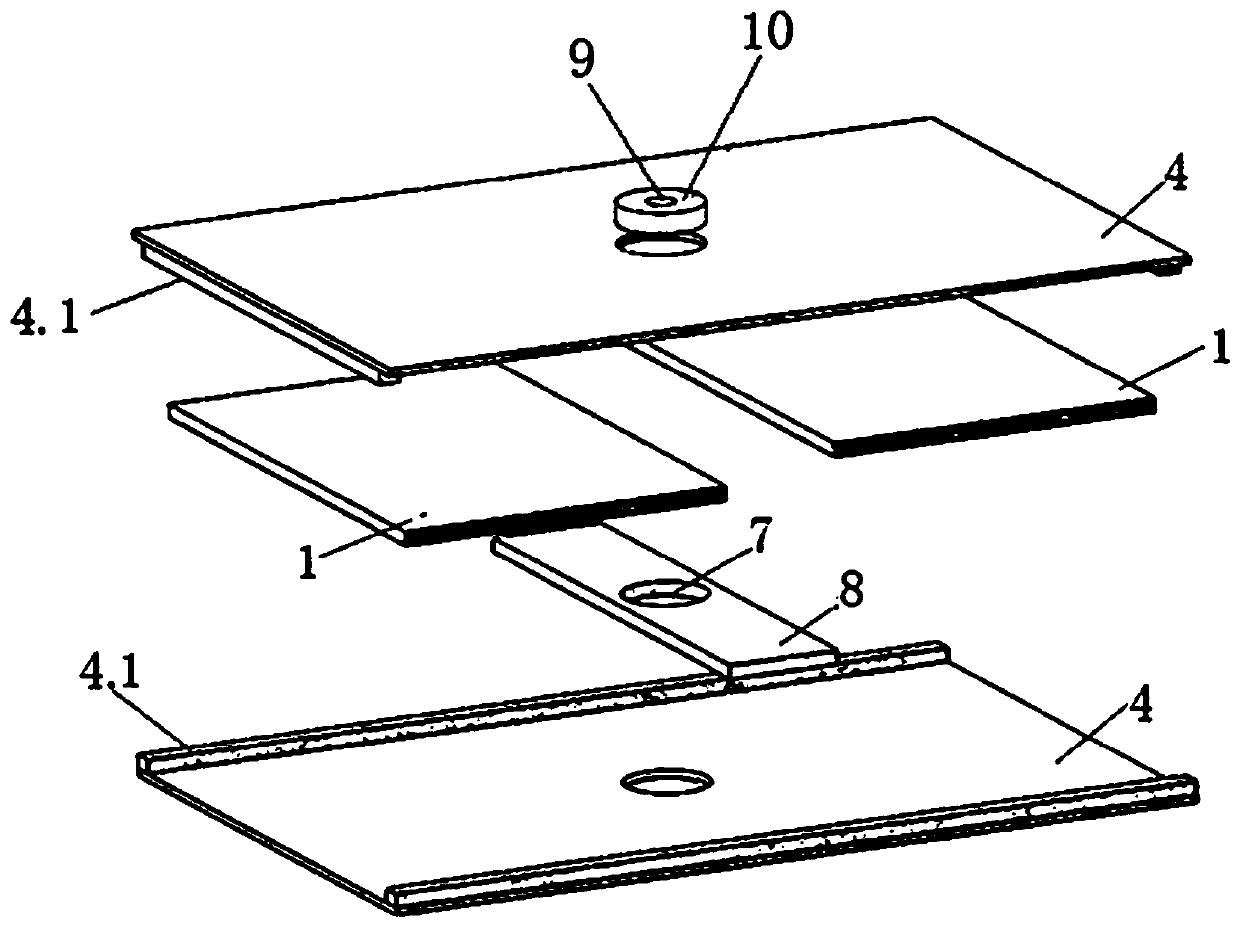

Vacuum thermal insulation plate with mounting holes and without fear of surface damage and processing technology

ActiveCN110792880ASimple structureGood insulation effectThermal insulationSynthetic resin layered productsEngineeringHot pressing

The invention discloses a vacuum thermal insulation plate with mounting holes and without fear of surface damage and a processing technology. The vacuum thermal insulation plate comprises an inner vacuum structural layer and at least one outer vacuum structural layer wrapped around the outer side of the inner vacuum structural layer, the inner vacuum structural layer is composed of an inner core plate body and a high vacuum barrier film wrapped around the outer side of the inner core plate body, the inner core plate body is prepared from materials such as glass fibers through a carding hot pressing or dispersion wet process and a vacuum technology, and the inner vacuum structural layer is prepared by using high vacuum heat sealing equipment; each outer vacuum structural layer is composed of an outer core plate body and a high vacuum barrier film wrapped around the outer side of the outer core plate body, each outer core plate body is prepared from materials such as glass fibers througha mixing dispersion wet process through a vacuum forming technology, a gettering material can be embedded into each outer core plate body, then each outer core plate body is put into the corresponding high vacuum barrier film, and the outer vacuum structural layers are prepared by using the high vacuum heat sealing equipment; and for mounting hole parts, the mounting holes are separated from thecore plate layers by using partition plates provided with through holes. The vacuum thermal insulation plate does not bulge, does not swell, does not absorb water and can retain the thermal insulationperformance after the surface of the vacuum thermal insulation plate is damaged.

Owner:安徽百特新材料科技有限公司

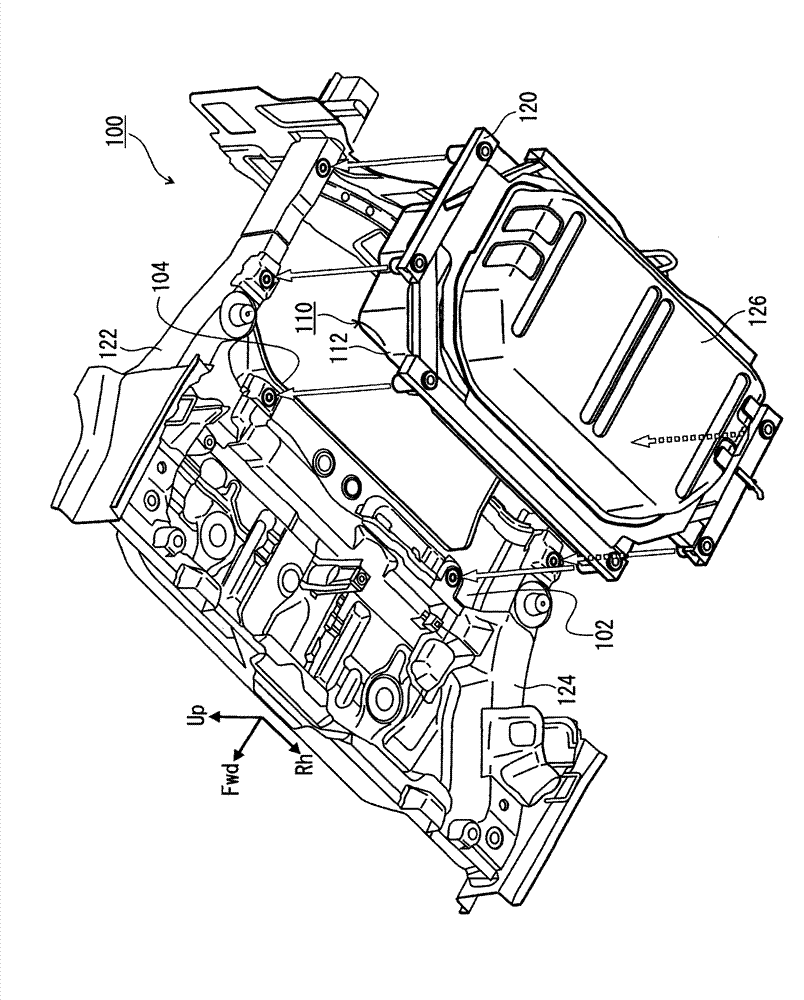

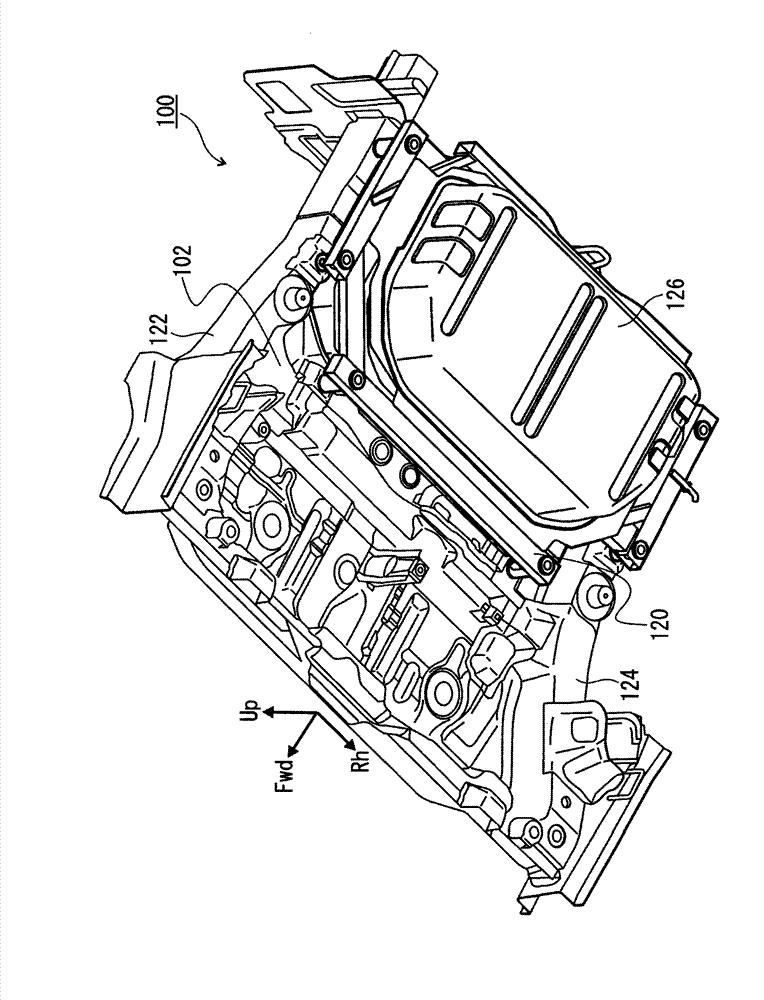

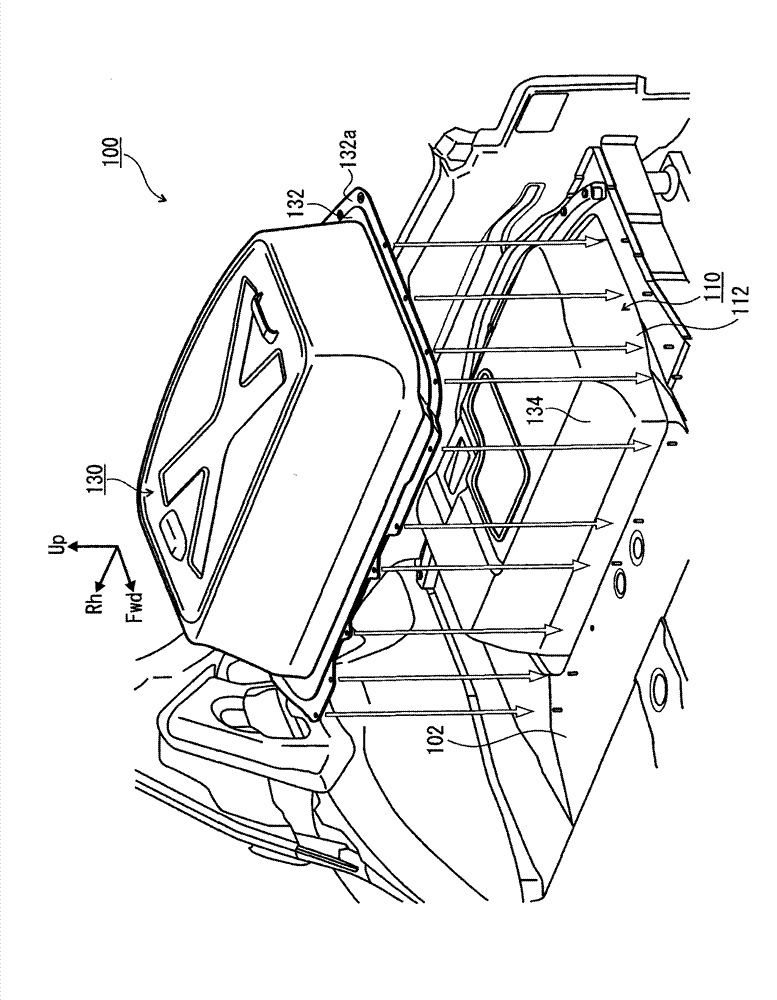

Car body structure

ActiveCN103029555AWeight increaseNo increase in production costElectric propulsion mountingSuperstructure subunitsElectric vehicleHybrid vehicle

The present invention provides a car body structure, which can be suitably provided with a battery unit without increasing the cost or the weight of the car, and can be used for a hybrid vehicle or an electric vehicle. The structure (100) has a bottom plate forming a bottom surface of a car body, an aperture (104) formed at the bottom plate, a battery unit (110) arranged in the aperture (104) and exposed from the upper side and the lower side of a rear bottom panel, a cover (130) made of resin and covering the upper portion of the battery unit (110) at the upper side of the bottom plate.

Owner:SUZUKI MOTOR CORP

Summer soybean simplified cultivation method

InactiveCN105027960AReturn to fieldNo increase in production costPlant cultivationCultivating equipmentsFertilizerSite management

The invention discloses a summer soybean simplified cultivation method and belongs to the technical field of soybean planting. The method comprises the steps of fine breed selection, sowing in good time, wheat straw utilization, seed fertilizer application, shallow rotary tillage and compacting, weed killer spraying, field management and the like. The method is easy and capable of shortening farming time. By the adoption of the method, the rate of emergence of soybean is quite high, seedlings are uniform and strong, and a foundation is laid for the high and stable yield of soybean; production cost is low, and then cost saving and effectiveness increasing are achieved; by means of straw mulching, the organic content of soil is increased, soil fertility is improved, the economical environment is protected, resource utilizing efficiency is improved, and sustainable agricultural development is promoted. The method has vital practical significance in developing soybean production and guaranteeing food security in China.

Owner:JIANGSU XUHUAI DISTRICT XUZHOU AGRI SCI INST

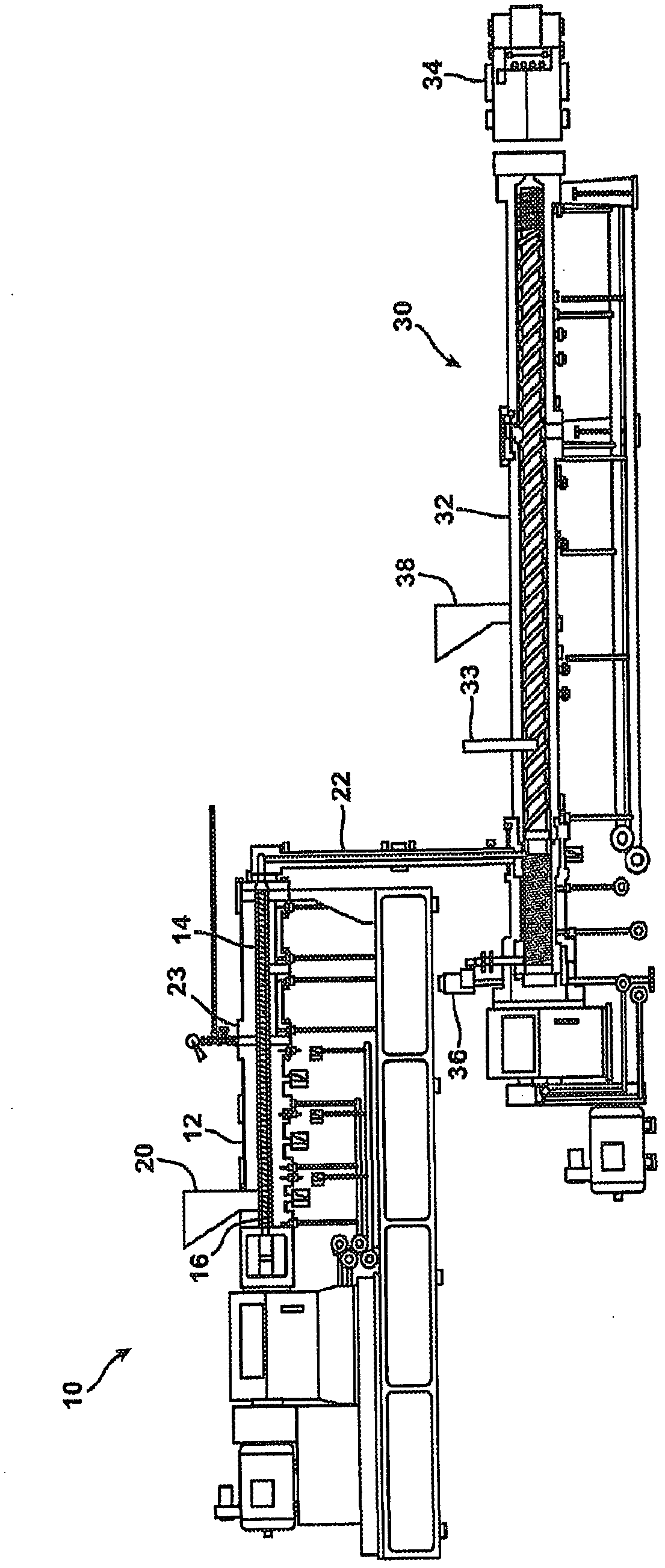

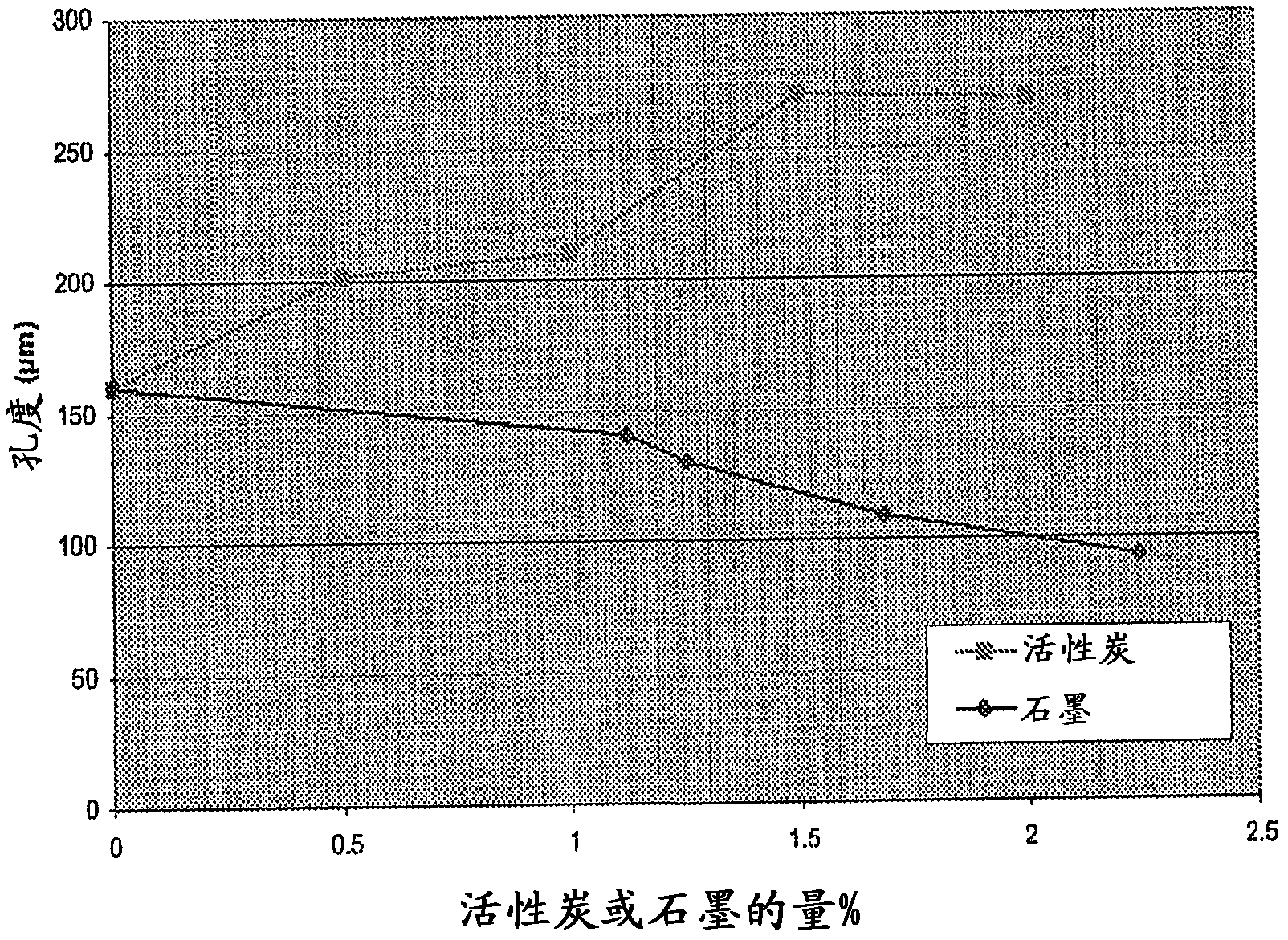

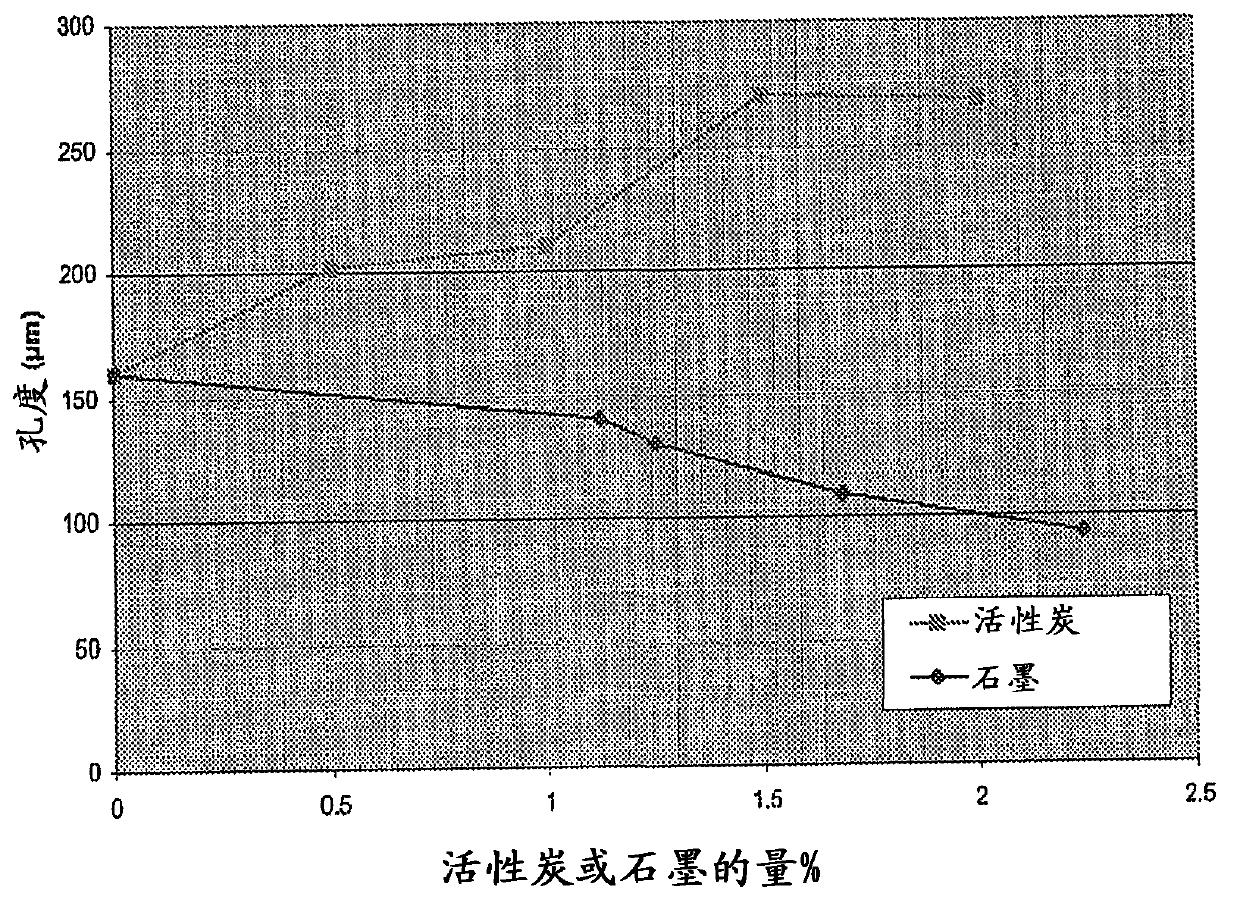

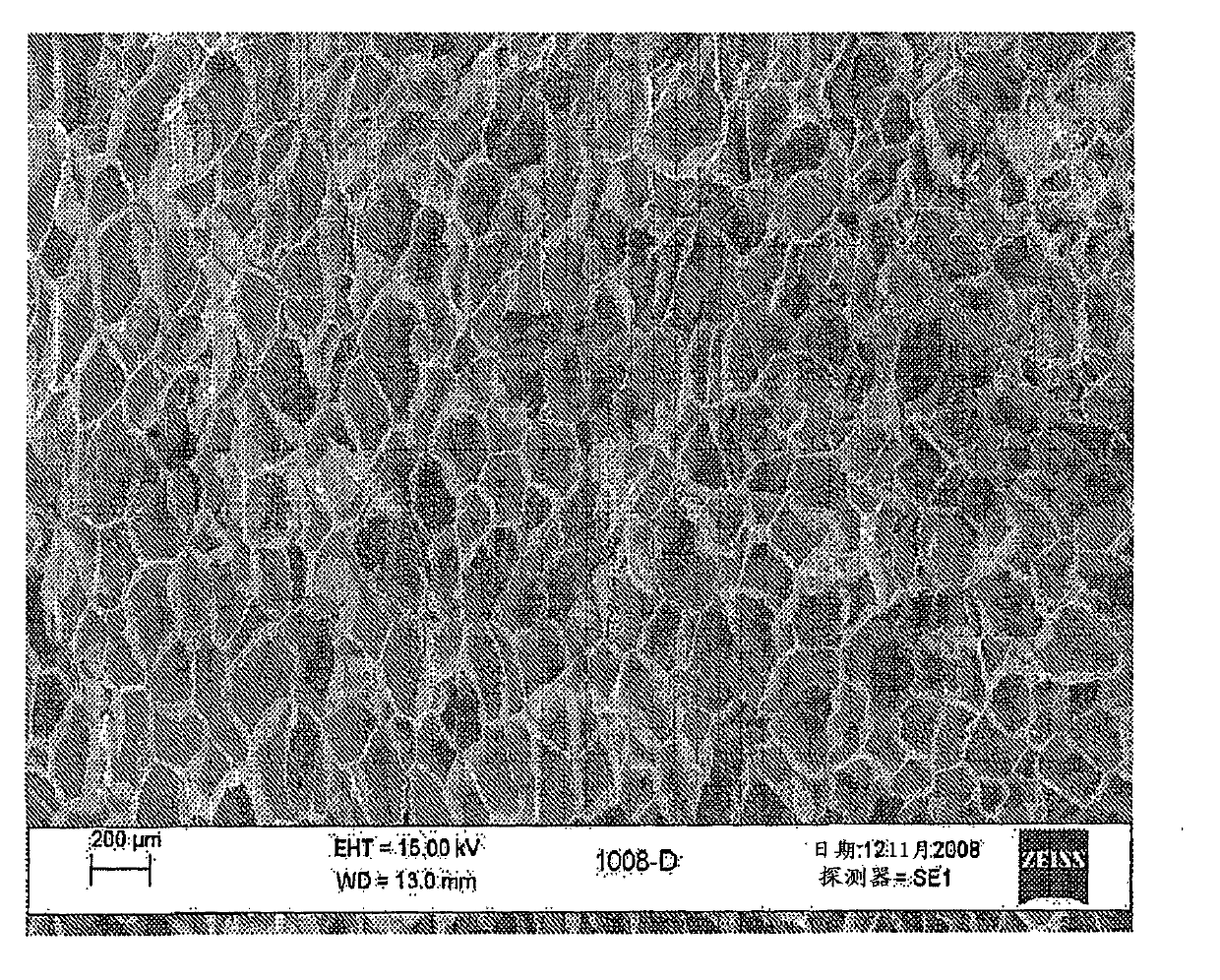

Porous carbon-containing compounds as water carriers and cell size controlling agents for polymeric foams

Polymeric foam and polymeric foam products that contain a foamable polymer material, at least one blowing agent, activated carbon, and water are provided. The activated carbon acts as both a water absorbent and carrier for the water. The activated carbon is able to control and increase cell size even in the presence of carbon dioxide, HFCs, and / or infrared attenuating agents. Additionally, the activated carbon permits a desired amount of water to be introduced into the polymer melt. By controlling the amount of activated carbon and its water content during an extrusion process, a broad range of cell sizes can be obtained in the extruded product. In exemplary embodiments, the activated carbon is added to a primary extruder and water is directly injected into a secondary extruder. Alternatively, the activated carbon is compounded with a polymer resin, pre-hydrated by conditioning or steam impregnation, and added to a primary or secondary extruder.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

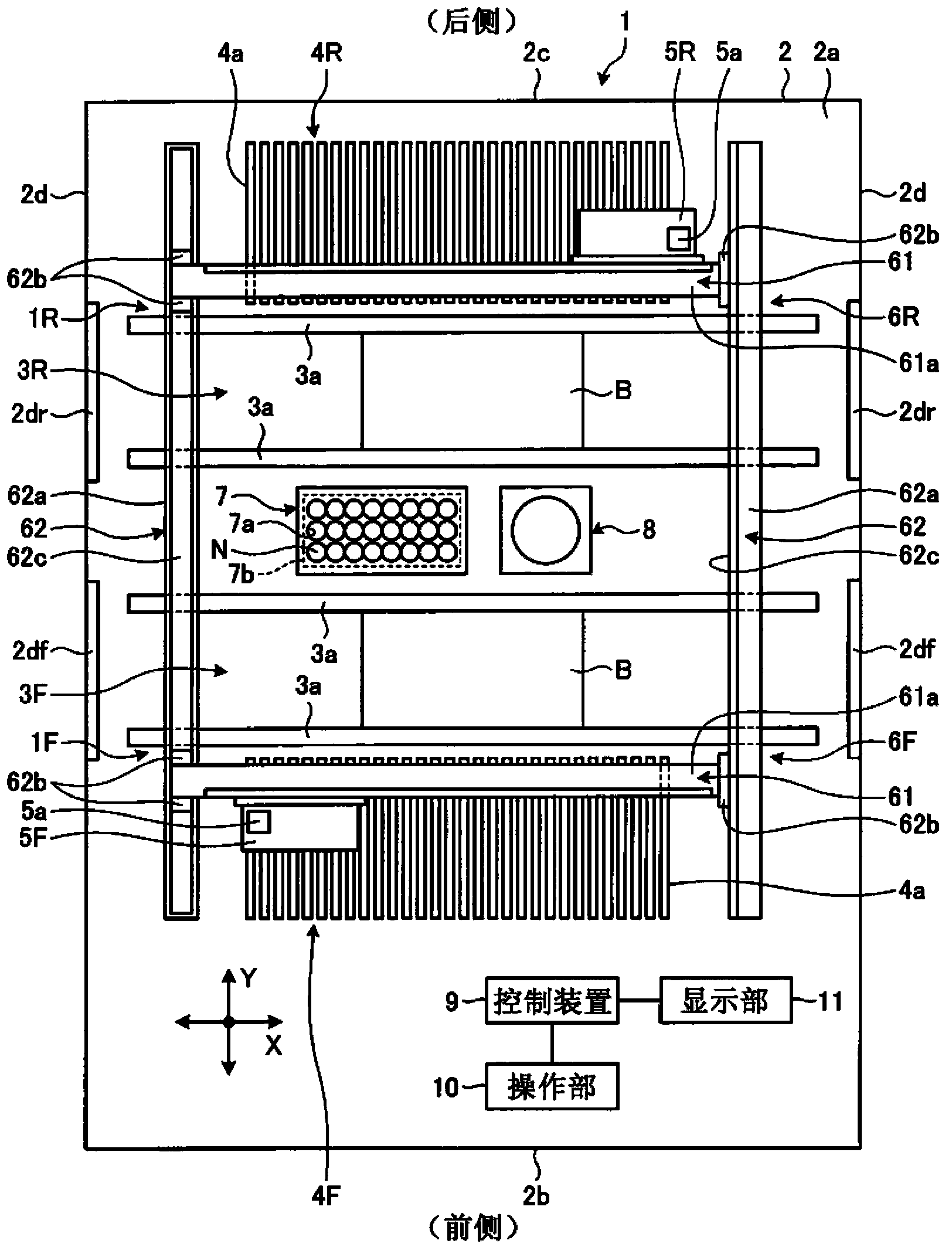

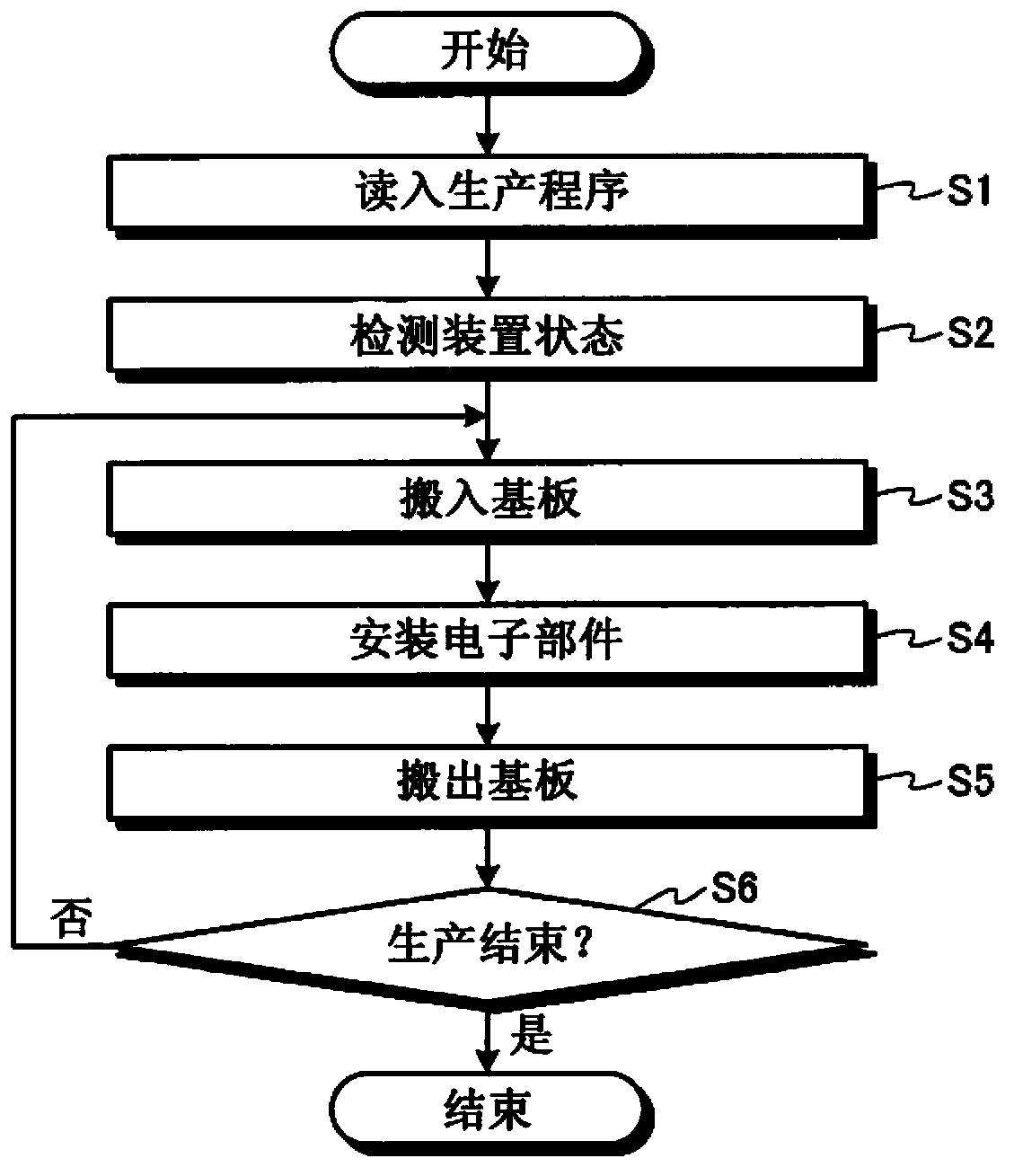

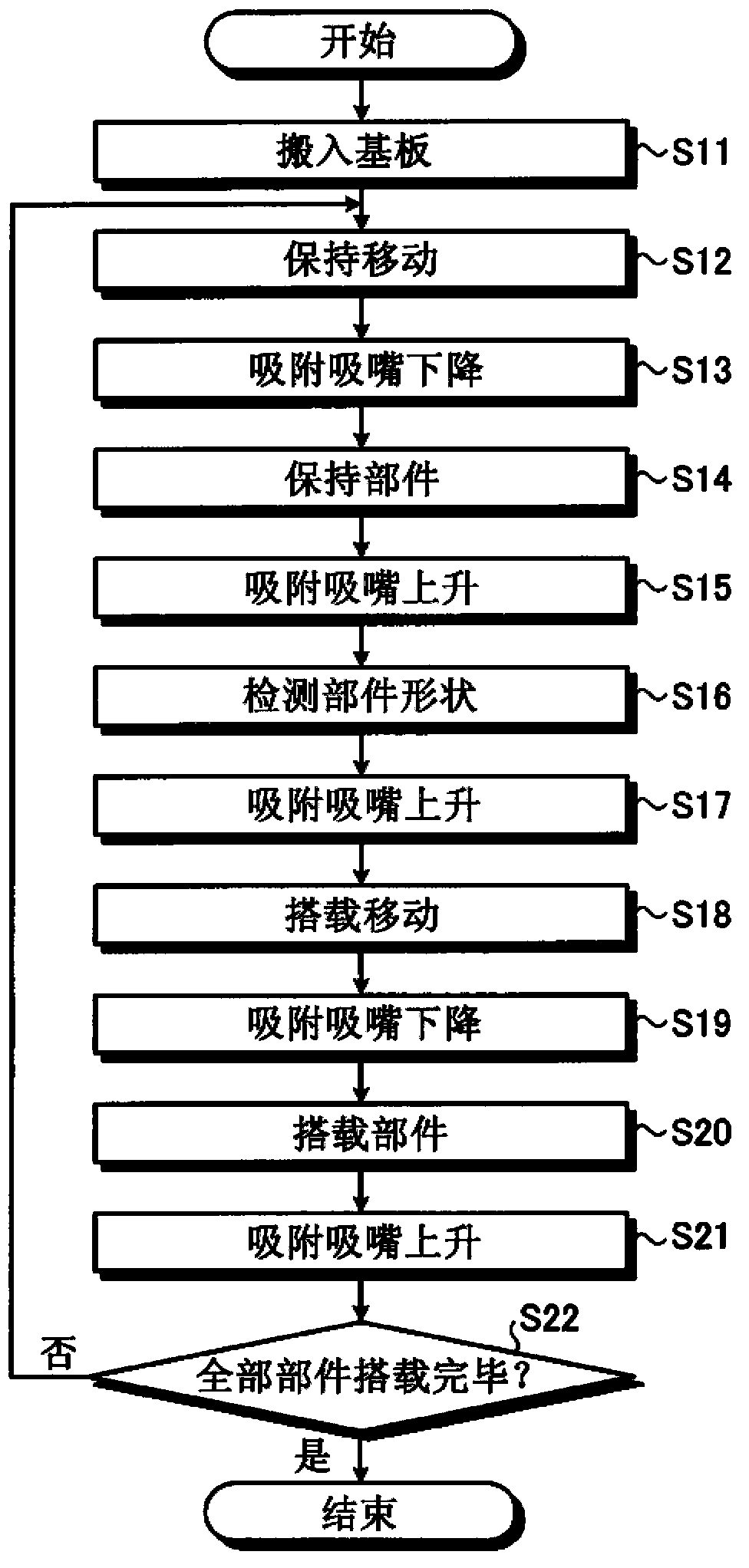

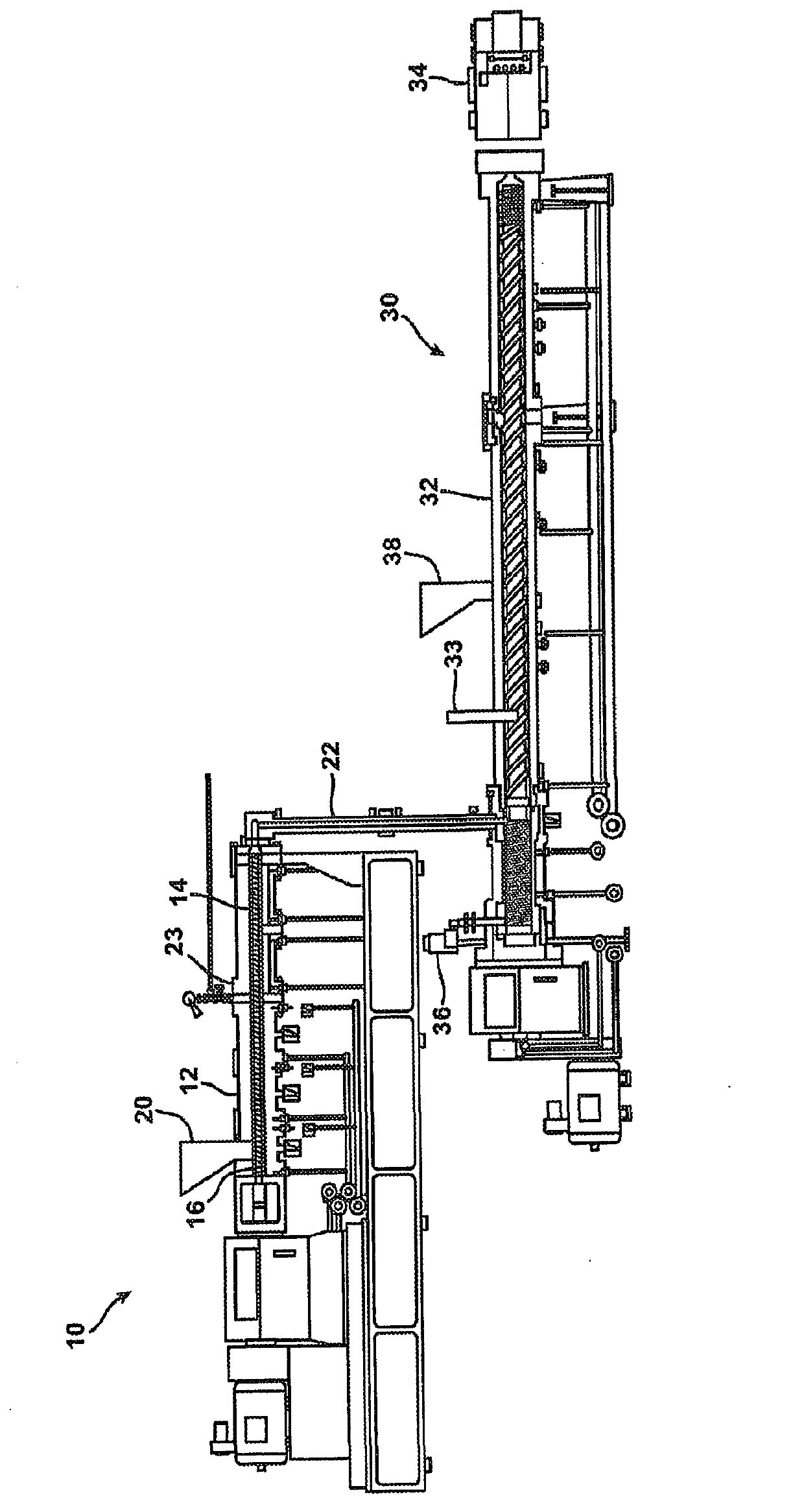

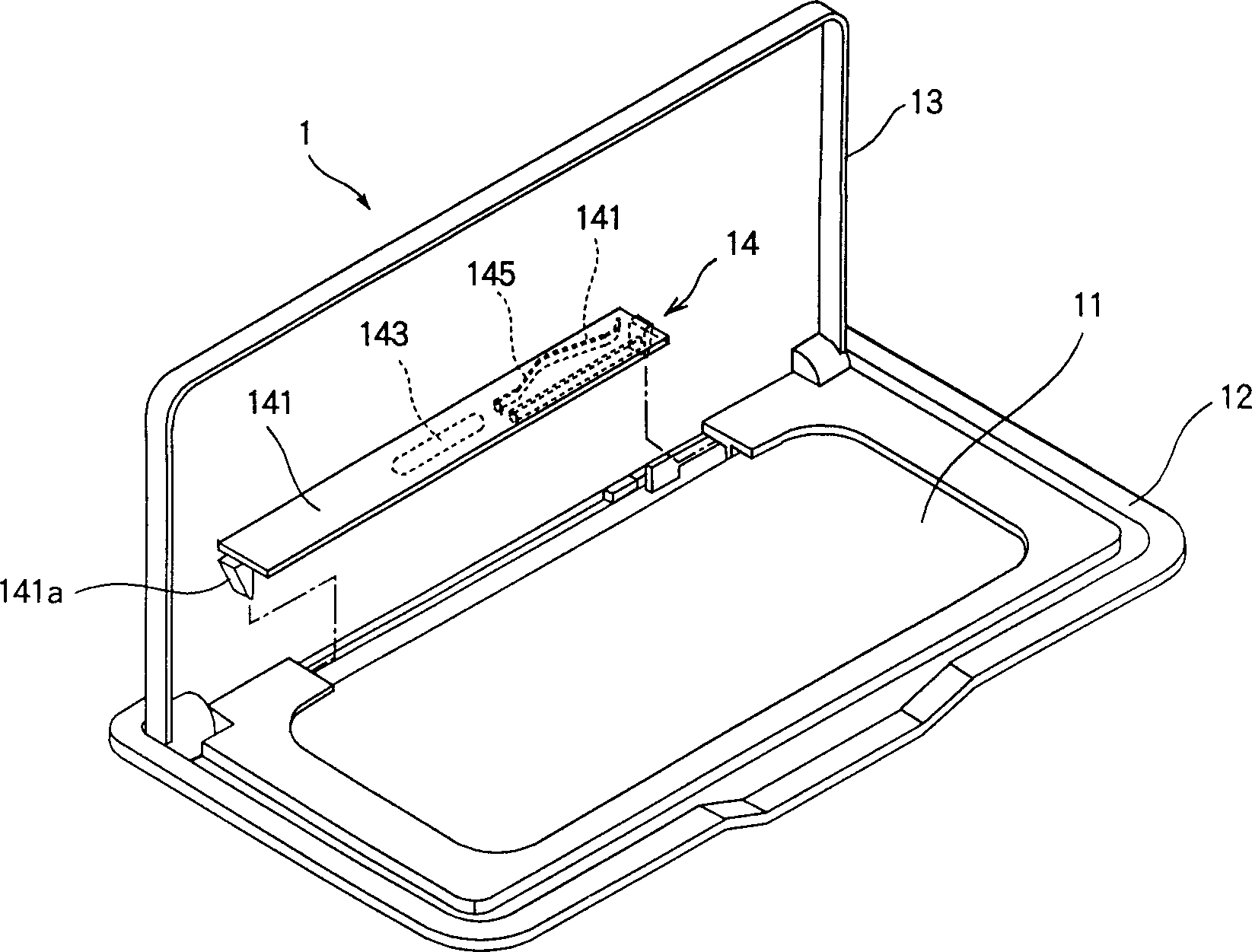

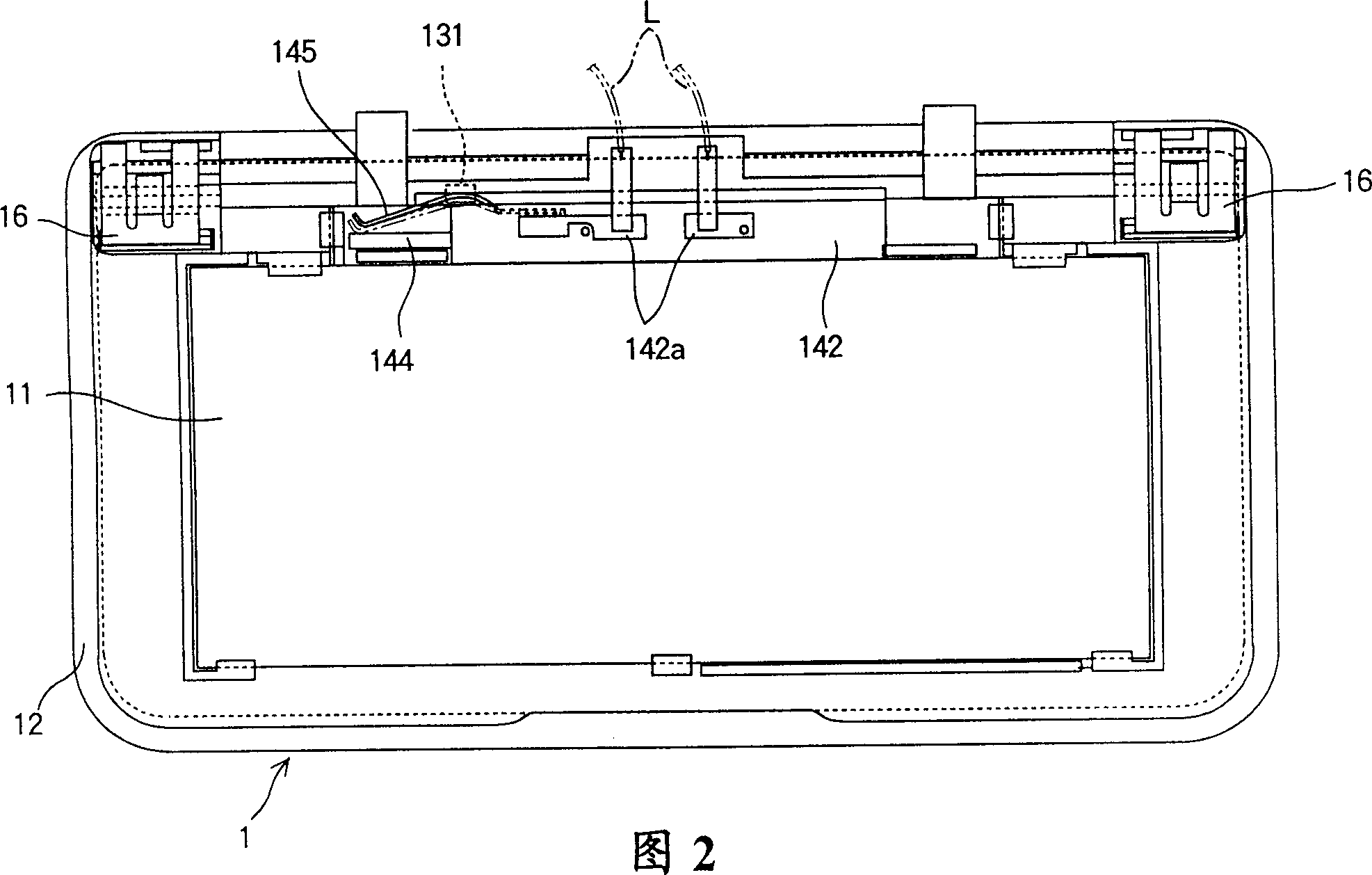

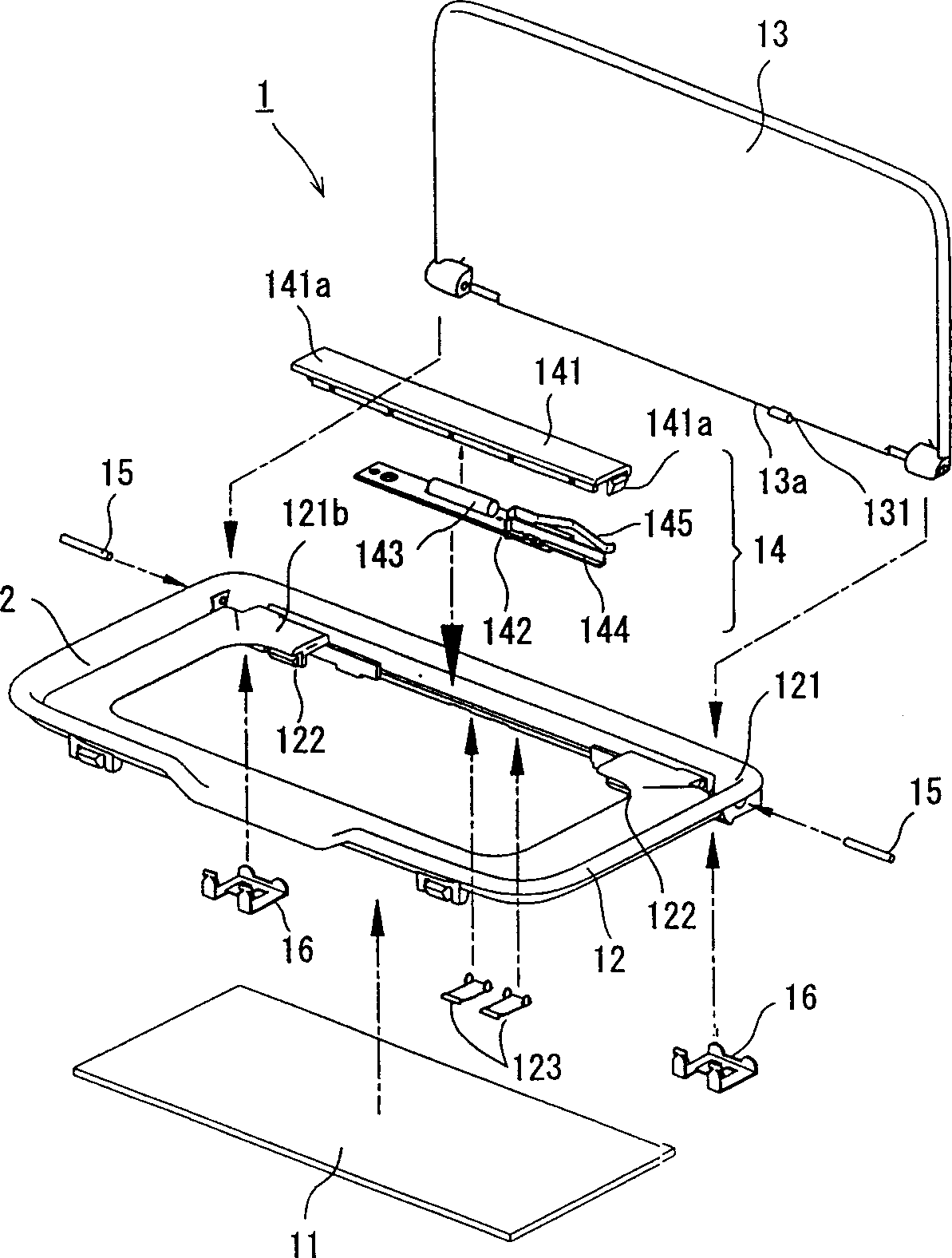

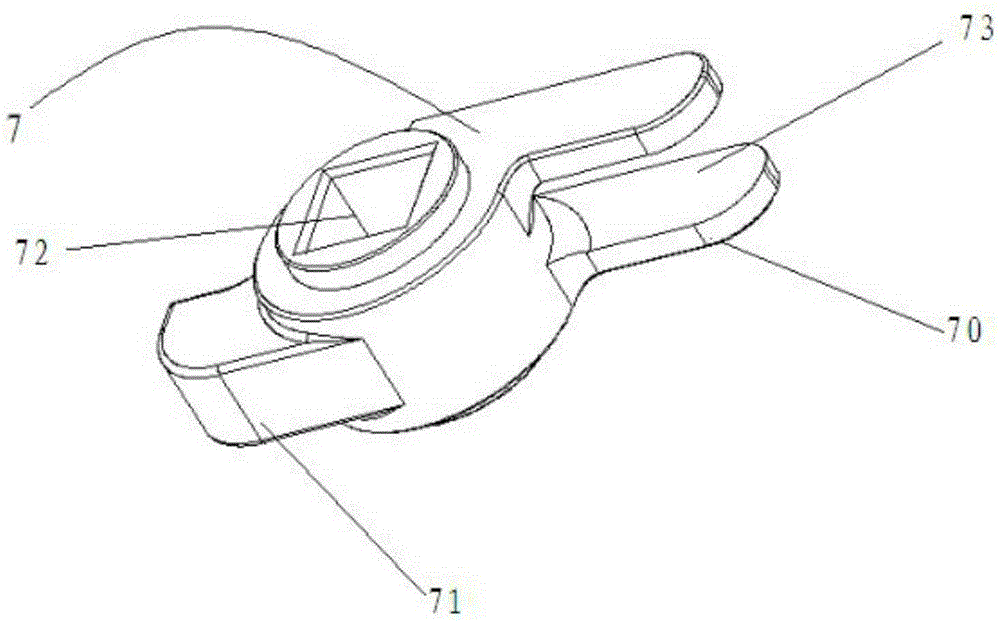

Electronic component mounting apparatus

InactiveCN103429067AExtended range of movementNo increase in production costElectrical componentsNozzleElectronic component

The present invention provides an electronic component mounting apparatus based on the replacement of the common nozzle of the adsorption suppressing increase in size and production cost of the entire device. In the substrate for mounting an electronic component (B) on the electronic component mounting apparatus (1) comprising: a plurality of substrate transfer unit (3F, 3R), it will transport the substrate (B) is arranged parallel to the substrate conveyor line; more mounting head (5F, 5R), which is detachably attached to the electronic component for attracting and holding the adsorption nozzle (N), is set to, can be adsorbed by the suction nozzle (N) to the adsorption of the electronic component held by the substrate transfer unit (3F, 3R) mounted substrate moves; replacement unit and multiple nozzle (7), which is disposed between the substrate conveying portion (3F, 3R), can be placed in different types of adsorbing and holding the electronic components were replaced with a adsorption nozzle (N).

Owner:JUKI CORP

Porous carbon-containing compounds as water carriers and cell size controlling agents for polymeric foams

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

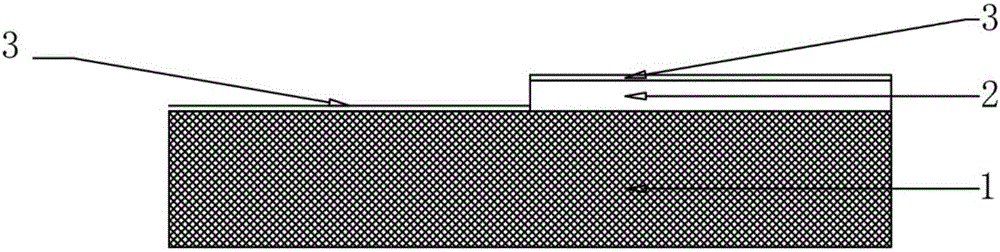

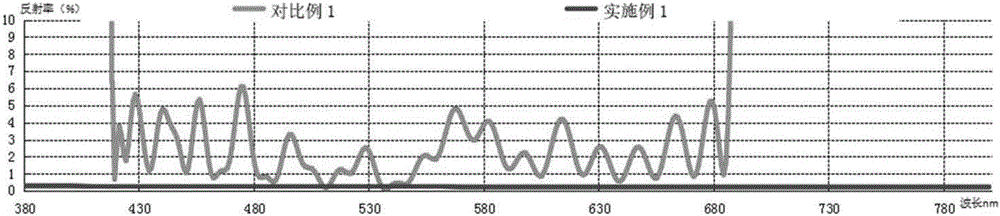

Low internal reflection composite base material and manufacturing method thereof

InactiveCN106597590ALow internal reflectionSimple manufacturing processOptical filtersAbsorption effectTotal internal reflection

The invention discloses a low internal reflection composite base material and a manufacturing method thereof. In the base material, a filtering or absorption effect of a shielding layer to light can be realized and ultralow internal reflection can be maintained. Compared to the base material of the shielding layer arranged on a routine coating film layer, the base material of the invention can be as low as 0.1%-0.2% (420nm-680nm). A manufacturing technology of the base material is simple. Compared to the manufacturing technology of the traditional base material which is coated with the shielding layer, a complex degree of the technology in the invention is not increased, and production cost is not increased either and even is decreased.

Owner:GUANGZHOU JIAHE PHOTOELECTRIC TECH CO LTD

Manufacturing process of large-aperture variable-turn-angle PVC (polyvinyl chloride) pipe

InactiveCN103692671ARealize small angle bendingChanging the Turning DilemmaTubular articlesTurn angleEconomic benefits

The invention relates to a manufacturing process of a large-aperture variable-turn-angle PVC (polyvinyl chloride) pipe. The manufacturing process comprises the following five steps: mixing, extruding, performing cooling and forming, performing fixed-length cutting, flaring and packaging for sale. According to the manufacturing process, an improved flaring mould is adopted, so that a pipe opening of the large-aperture PVC pipe can be bent at a small angle, the problem that an existing PVC straight pipe makes a turn through a connecting piece is solved, and a processing process of the flaring step is correspondingly changed; a process step of horizontally rotating the flaring mould is added on the basis of an existing flaring machine, so that the large-aperture PVC pipe can be bent; the flaring mould in the process is convenient to use, the effect is remarkable, the manufacturing process is simple, and good economic benefit can be created.

Owner:山东华信塑胶股份有限公司

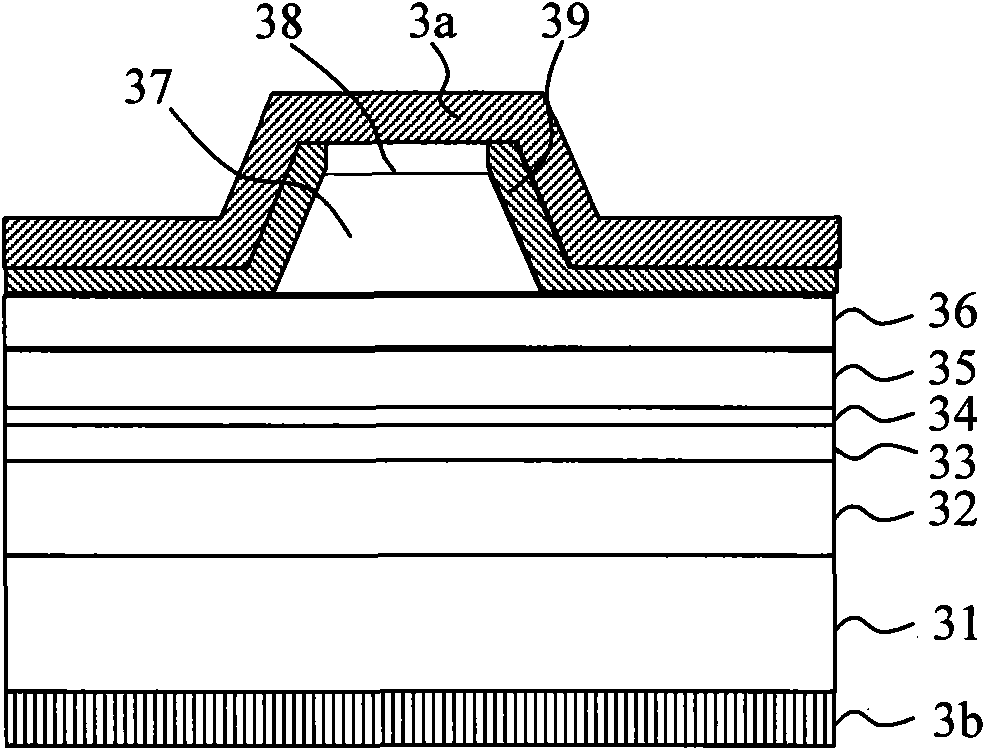

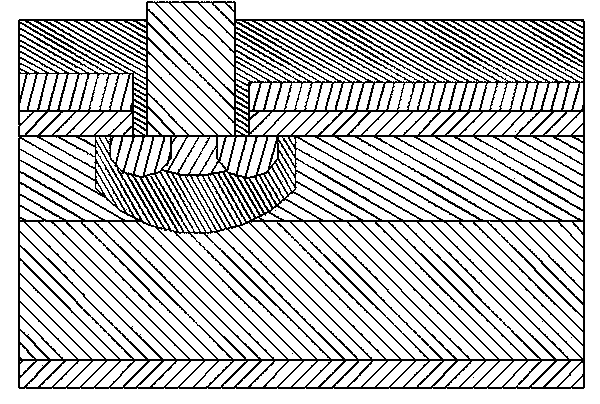

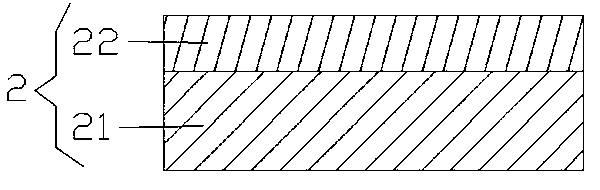

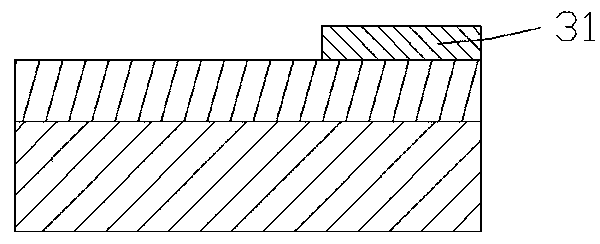

Power device with electrostatic protection structure and manufacturing method thereof

InactiveCN104300000ASimple preparation processImprove space efficiencySemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingZener diodeEngineering

The invention discloses a power device with an electrostatic protection structure and a manufacturing method of the power device. The power device with the electrostatic protection structure comprises a drifting layer, a drain region, a drain electrode, a P- doped region, a first N+ doped region, a P+ doped region, a first insulating film, a second insulating film, a polycrystalline silicon layer, a gate electrode, an electrostatic protection layer, a third insulating film, a source electrode, an electrostatic electrode and a conductor layer. The electrostatic protection layer comprises a plurality of second P- doped regions and a plurality of second N+ doped regions, wherein the second P- doped regions and the second N+ doped regions are arranged alternately. By alternately arranging the P- doped regions and the second N+ doped regions in the power device, an electrostatic protection layer-Zener diode structure is formed, and thus space in a power module will not be occupied by an electrostatic protection circuit and the like while an electrostatic protection structure does not need to be additionally arranged, the space efficiency of the power module is improved, the number of wires and the number of some parasitic parameters are reduced, and the efficient power device is obtained.

Owner:SHENZHEN KIA SEMICON TECH

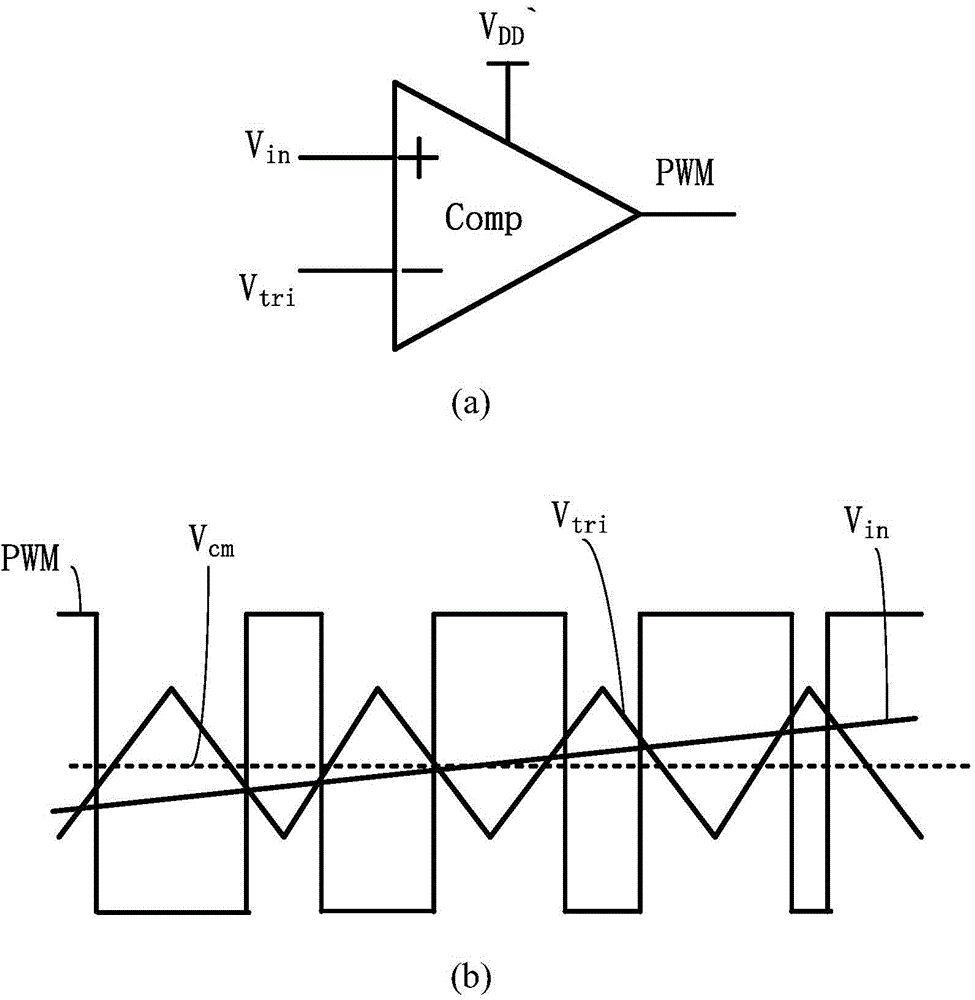

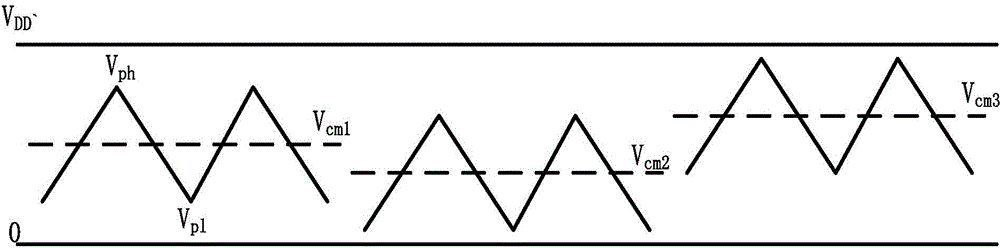

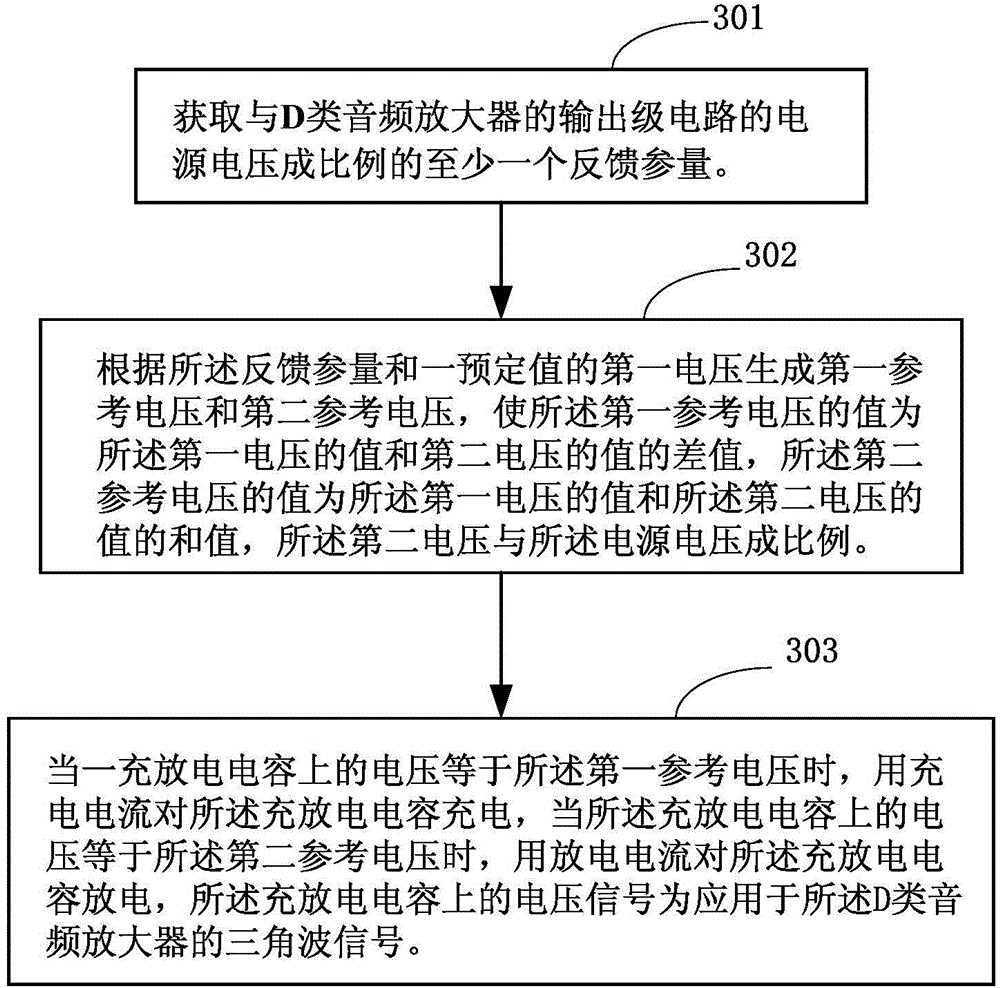

Triangular wave generating method and triangular wave generating circuit applied to D-class audio frequency amplifier

ActiveCN104104343AGuaranteed accuracyGuaranteed stabilityAmplifier with semiconductor-devices/discharge-tubesCapacitanceVoltage reference

The invention discloses a triangular wave generating method and a triangular wave generating circuit applied to a D-class audio frequency amplifier. The triangular wave generating method includes forming first reference voltage and second reference voltage according to feedback parameters in proportion to power supply voltage at an output stage of the D-class audio frequency amplifier and first voltage with a preset value, and enabling values of the first reference voltage and the second reference voltage to be a difference value and a sum value of the value of the first voltage and a value of second voltage in proportion to the power supply voltage respectively; using charging current and discharging current to charge and discharge a charge-discharge capacitor respectively, and enabling the first reference voltage and the second reference voltage to be a wave valley and a wave peak of voltage on the charge-discharge voltage; acquiring triangular waves, with common mode voltage to be the first voltage constantly and with amplitude in proportion to the power supply voltage, at two ends of the charge-discharge capacitor. When the triangular waves generated by the method are applied to the D-class audio frequency amplifier, accuracy in outputting of PWM (pulse width modulation) signals can be guaranteed, stability of a loop can be ensured without sacrificing power consumption and area performance, and increasing of production cost is avoided.

Owner:上海矽力杰微电子技术有限公司

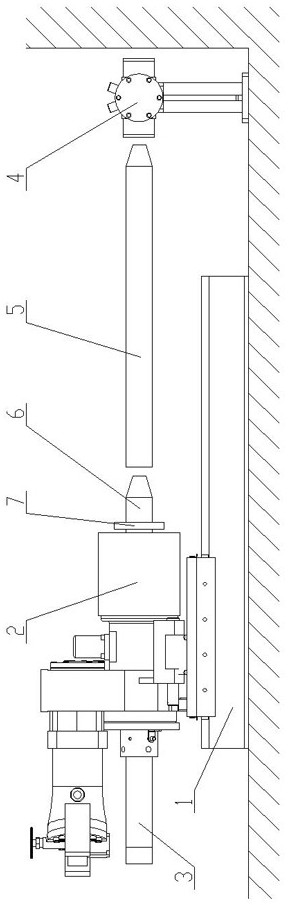

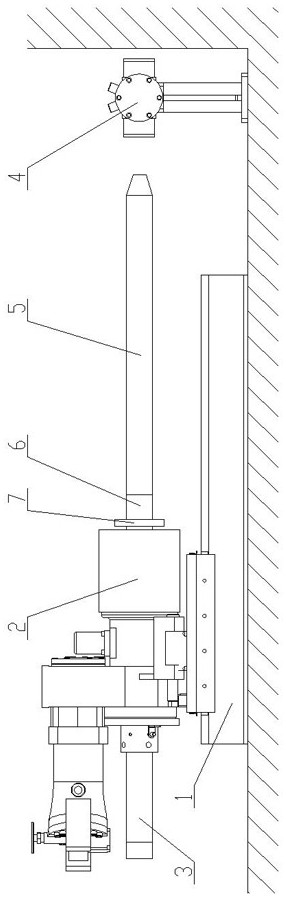

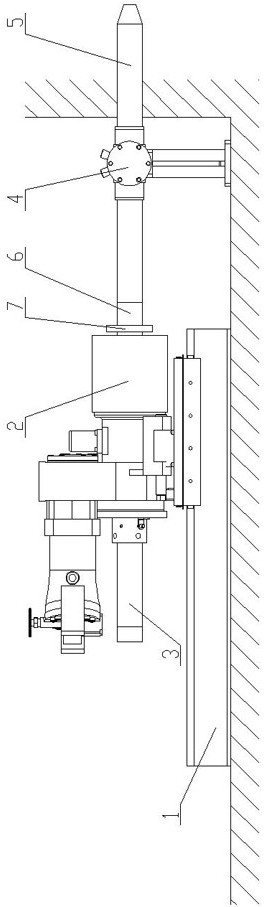

Middle rod adding method of guide rail type drilling device

InactiveCN111927348AReduce frequent disassemblySimple and fast operationDrilling rodsConstructionsEngineeringStructural engineering

The invention discloses a middle rod adding method of a guide rail type drilling device. The method comprises the steps that a clamp holder is installed between a guide rail and a wall surface of thedrilling device, a common rod is clamped to a power head of the drilling device, then the tail of a drill rod is connected with the head of the common rod, and then the power head moves to be close tothe wall surface to be drilled; the drill rod is driven by the power head to rotate, and after penetrating through the clamping hole of the clamp holder, the head of the drill rod starts to drill a hole in the wall surface; after the power head moves to the limit position close to the wall surface, the power head stops driving the drill rod to rotate, then the clamp holder clamps the drill rod, the power head loosens the common rod, then the power head reversely moves along the guide rail and is far away from the drilled wall surface, then the tail of the common rod is clamped through the power head, and the clamp holder loosens the drill rod; and then the power head moves again to be close to the wall face to be drilled, the drill rod is continuously driven to rotate through the power head, the drill rod continuously drills into the wall face, and therefore the effect of adding the rod in the middle when the pushing stroke of the power head is smaller than the length of the drill rodis achieved.

Owner:HENAN TIEFULAI EQUIP MFG CO LTD

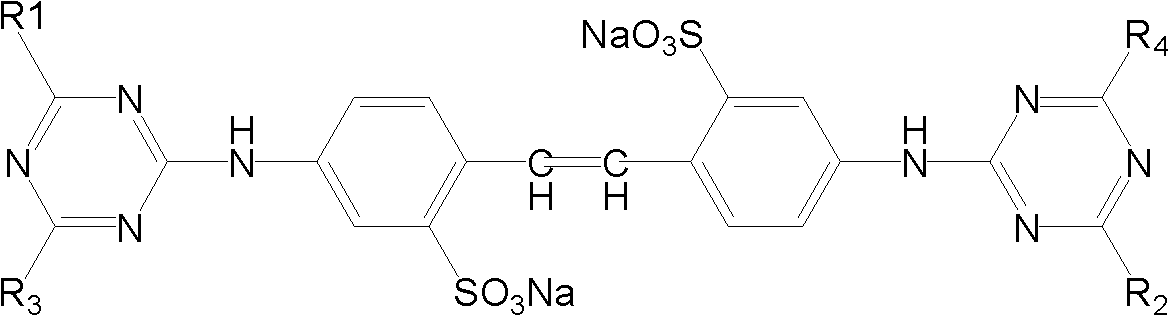

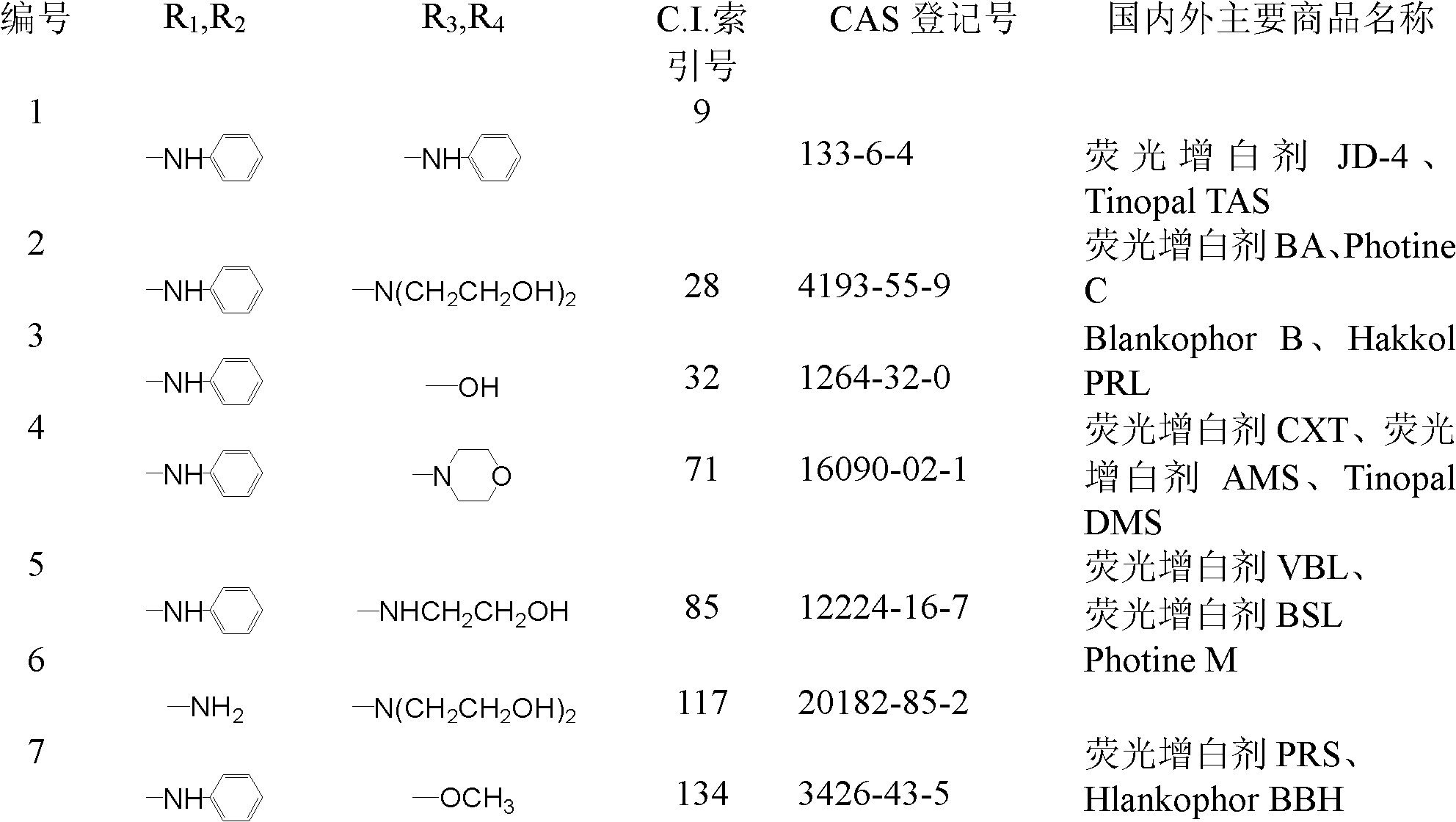

Crystal transfer method for triazinyl amino toluylene fluorescent brightening agent

InactiveCN102504601ANo pollutionNo increase in production costStyryl dyesLuminescent compositionsFluorescenceSlurry

The invention belongs to the technical field of fluorescent brightening agent, in particular to a crystal transfer method for triazinyl amino toluylene fluorescent brightening agent. The invention mainly provides the crystal transfer method for the triazinyl amino toluylene fluorescent brightening agent, which is used for transferring the unstable straw yellow Alpha unformed triazinyl amino toluylene fluorescent brightening agent into stable white Beta type triazinyl amino toluylene fluorescent brightening agent. The crystal transfer method comprises the steps as follows: 1, mixing water with Beta type triazinyl amino toluylene fluorescent brightening agent to obtain Beta type seed crystal slurry; 2, adding the Beta type seed crystal slurry into the third condensation reaction liquid in the manufacturing process of the triazinyl amino toluylene fluorescent brightening agent to undergo backflow reaction for 1 to 6 hours; and 3, after the reaction, reducing the temperature to 40 to 100 DEG C, filtering, and drying to obtain the Beta type triazinyl amino toluylene fluorescent brightening agent. The invention has the advantages of low cost, zero contamination, simplicity in treatment, and the like.

Owner:山西青山化工有限公司

Low-shrinkage cathode paste

The invention discloses a low-shrinkage cathode paste, which consists of dry ingredients and a binder, wherein the binder accounts for 16 to 20 percent of the total weight of the cathode paste and the dry ingredients account for 80 to 84 percent of the total weight of the cathode paste; and the dry ingredients comprise electrically-calcined coal, pitch coke and artificial graphite, the electrically-calcined coal accounts for 59 to 65 percent of the total weigh of the dry ingredients, the pitch coke accounts for 5 to 11 percent of the total weigh of the dry ingredients, and the artificial graphite accounts for 27 to 33 percent of the total weigh of the dry ingredients. The requirement on the granularity of a powder material in the electrically-calcined coal is that 200 mesh powder accountsfor 47 to 53 percent of the total weight of the powder material. The requirement on the granularity of a powder material in the pitch coke is that 200 mesh powder accounts for 47 to 53 percent of thetotal weight of the powder material. The requirements on the granularity of the artificial graphite are that the granularity of the artificial graphite is less than 4.5 millimeters, that a granular material accounts for 30 to 36 percent of the total weight of the artificial graphite, and that a powder material accounts for 64 to 70 percent of the total weight of the artificial graphite. Powder having a granularity of 200 meshes accounts for 47 to 53 percent of the total weight of a powder material in the artificial graphite. Compared with the prior art, the cathode paste has the advantages ofimproving the surrounding environment of an aluminum potroom, prolonging the service life of an aluminum cell, reducing cell voltage, energy consumption and production cost and the like due to reduced electrical resistivity, improved electrical conductivity and obviously reduced expansivity and shrinkage.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

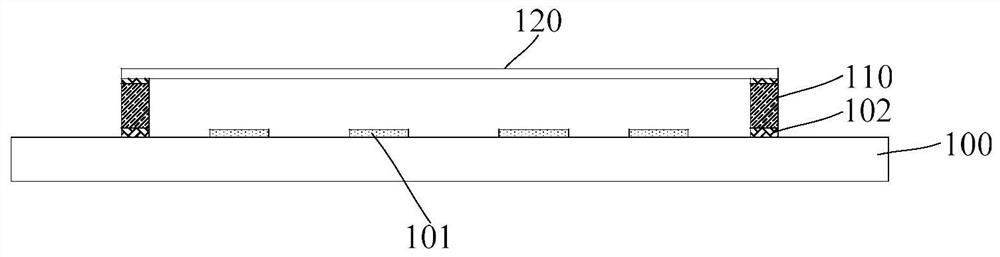

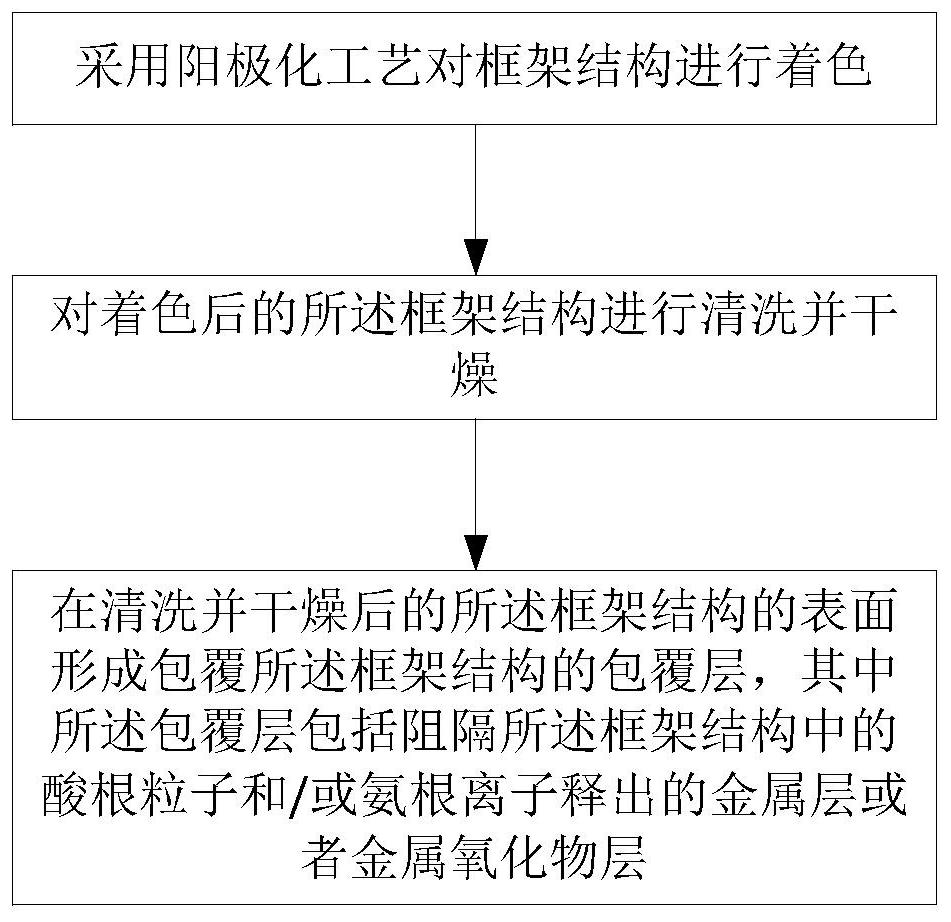

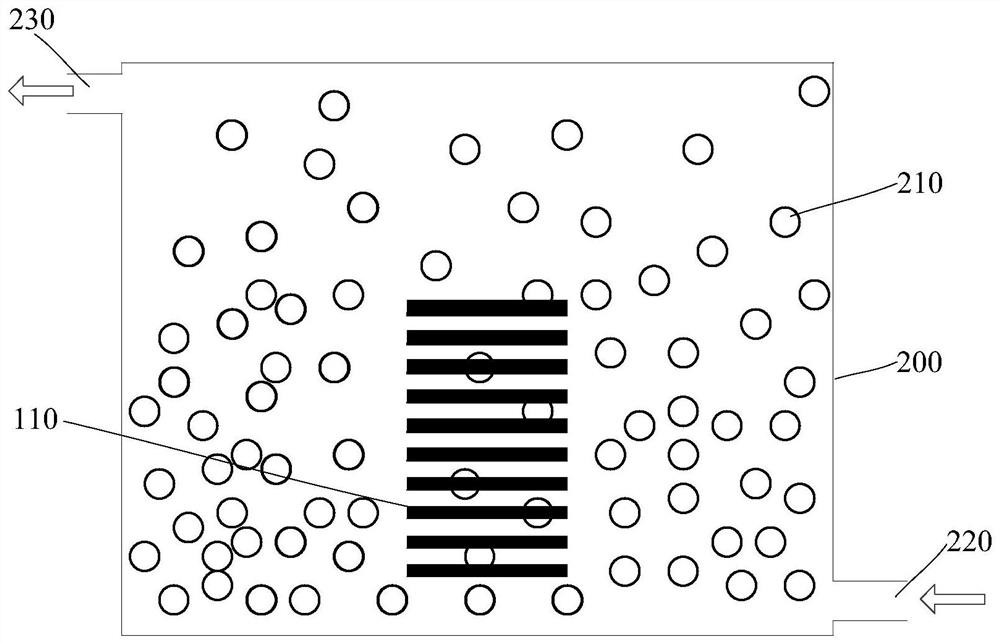

Protective film frame, preparation method thereof and protective film assembly

PendingCN112445063AWith dielectric insulationMolecular stabilizationVacuum evaporation coatingSputtering coatingFilm framePhotomask

The invention provides a protective film frame, a preparation method thereof and a protective film assembly. The protective film frame comprises a frame structure and a coating layer coating the surface of the frame structure, and the coating layer comprises a chromium layer or a titanium dioxide layer. The coating layer coats the surface of the frame structure, so that acid radical / ammonia radical ions (SO4<2->, PO4<3-> and NH<4+>) in the frame structure are coated and isolated from the outside, the release of the acid radical / ammonia radical ions (SO4<2->, PO4<3-> and NH<4+>) in the exposureor after-exposure storage period of a photoetching machine is avoided, and the irregular generation of white fog (Haze) by a photomask is avoided. According to the protective film frame, the photomask is prevented from generating the white fog, so that the repeatability defect of the photomask with the white fog on a formed substrate can be effectively avoided, and the yield of the substrate canbe further improved.

Owner:SIEN QINGDAO INTEGRATED CIRCUITS CO LTD

Preparation method of tungstenic heteropolyacid catalyst

InactiveCN103071531AHigh yieldIncrease dosageOrganic-compounds/hydrides/coordination-complexes catalystsO-Phosphoric AcidPtru catalyst

The invention relates to a preparation method of a tungstenic heteropolyacid catalyst. The method comprises the following steps that (1) an appropriate amount of tungstic acid and an oxidant are contacted, heated and stirred until a solution is colourless; filtering is conducted; the solution is cooled to a room temperature for use; (2) phosphoric acid is weighed, diluted and then added to reaction liquid; a system is diluted by water; stirring is conducted for reaction; (3) hexadecylpyridinium chloride is dissolved in methylene chloride and dropwise added to a final solution obtained in Step (2); stirring is continued for reaction; and (4) the solution stands; an organic phase is separated; methylene chloride is distilled off in a water bath at 50-60 DEG C; and a light-yellow solid catalyst is obtained. The preparation method has a creative improvement based on the original preparation method, so that the yield is increased, the cost is lowered, the flow is simplified, and industrial production is easy to realize.

Owner:SOUTH CHINA UNIV OF TECH

Method of acidic extractant complexing extraction separation rare-earth element

InactiveCN100529123CLess investmentReduce pollutionProcess efficiency improvementHigh concentrationRare-earth element

Owner:NORTHEASTERN UNIV LIAONING

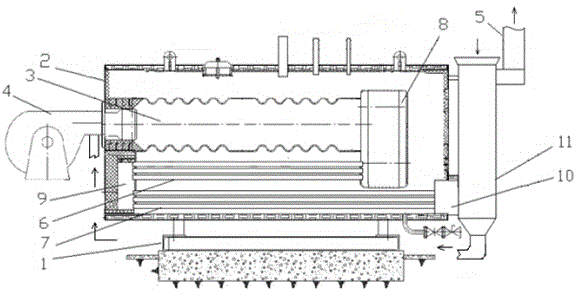

Efficient horizontal type condensational fuel industrial boiler

ActiveCN104949335AAbsorb high latent heat energyLower exhaust gas temperatureAir heatersSustainable buildingsSocial benefitsBoiler furnace

The invention discloses an efficient horizontal type condensational fuel industrial boiler, belongs to the technical field of fuel boilers, and is used for improving thermal efficiency of the condensational fuel industrial boiler. According to the technical scheme, the structure of a traditional fuel industrial boiler is broke through, a burner and a boiler furnace are arranged on the boiler, a condenser and a chimney are arranged below the burner and the boiler furnace, and the structure does not exist in designs of fuel industrial boilers at home and abroad and is creative. By means of the structure, not only can low-position heat display energy of smoke be absorbed, but also high-position latent heat energy of the smoke can be effectively absorbed, exhaust smoke temperature can be effectively lowered, smoke exhaust temperature ranging from 20 DEG C to 30 DEG C is far lower than the smoke exhaust temperature ranging from 150 DEG C to 250 DEG C of a conventional fuel industrial boiler at present, a miracle of the fuel industrial boiler is created, a new approach of the creativeness and development of fuel industrial boilers is opened up, and good economic benefit and social benefit are achieved.

Owner:河北盛淼安全技术工程有限公司

Dressing glass

InactiveCN1374055ANo increase in production costVehicle arrangementsAntiglare equipmentLens plateMechanical engineering

Owner:株式会社T&T

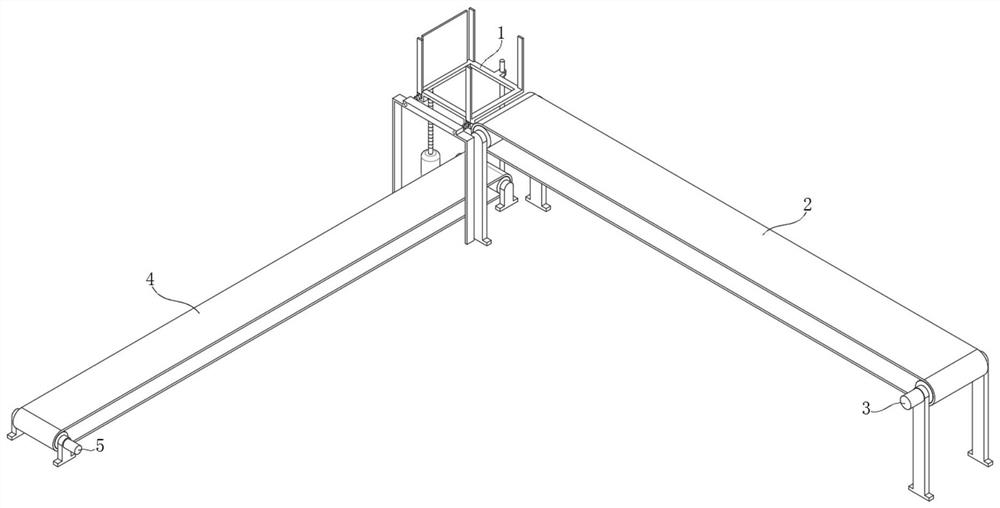

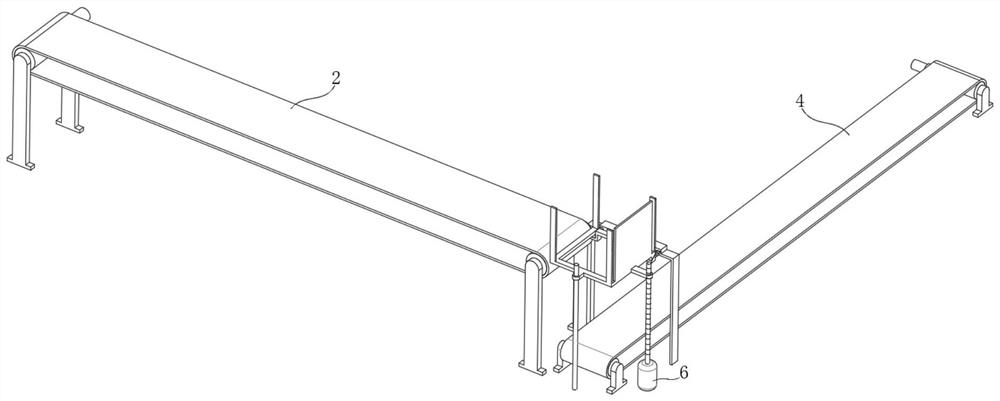

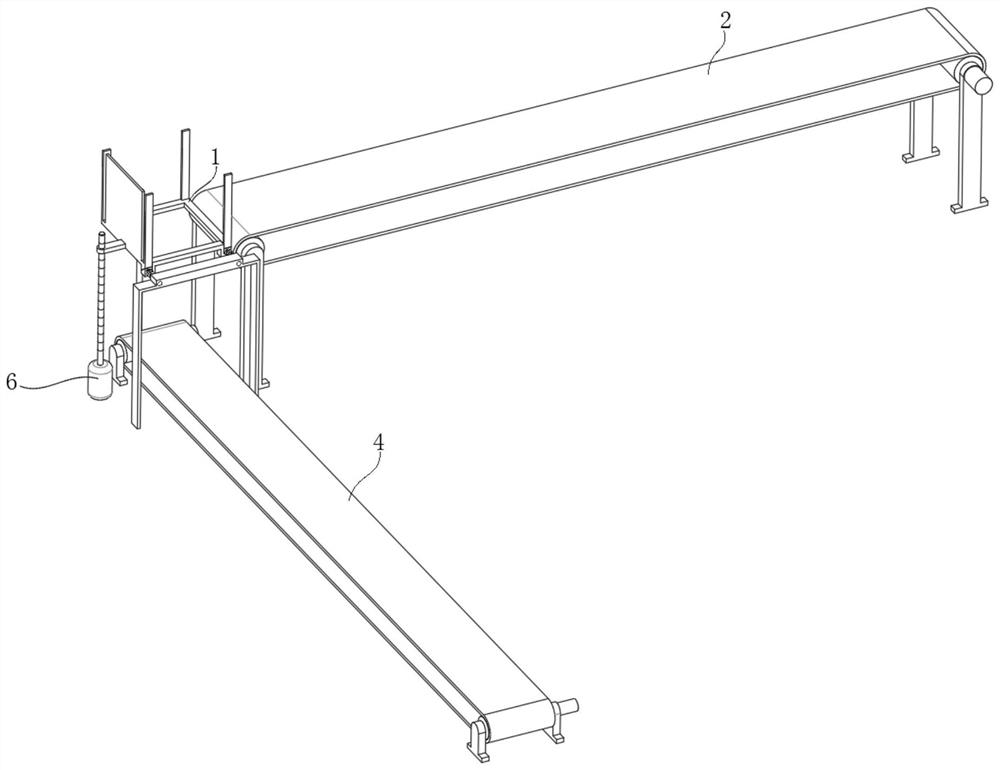

Automatic corrugated board stacking equipment

PendingCN113928900ASuitable for useImprove palletizing efficiencyPile receiversArticle deliveryStructural engineeringIndustrial engineering

The invention discloses automatic corrugated board stacking equipment, and relates to the technical field of stacking equipment. The automatic corrugated board stacking equipment comprises a first conveying assembly, a second conveying assembly and a stacking assembly, wherein the stacking assembly comprises a movable frame, when the first conveying assembly sequentially conveys unstacked corrugated boards to the movable frame, the movable frame continuously descends, the corrugated boards which are not stacked are stacked on the movable frame till the corrugated boards stacked on the movable frame fall on the second conveying assembly, and the second conveying assembly conveys the stacked corrugated boards away. According to the automatic corrugated board stacking equipment, the first conveying assembly conveys the unstacked corrugated boards to the movable frame in sequence, so that the unstacked corrugated boards are stacked on the continuously descending movable frame, the stacked corrugated boards on the movable frame fall on the second conveying assembly, and then the stacked corrugated boards are conveyed away through the second conveying assembly, a corrugated board stack is completed, and the stacking efficiency is higher.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

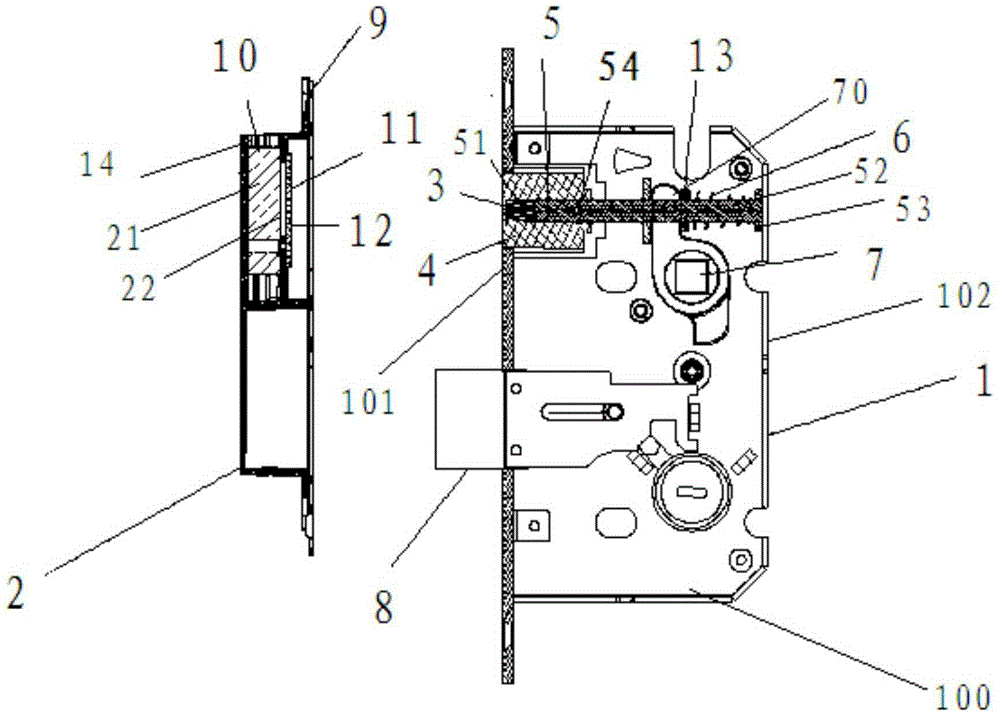

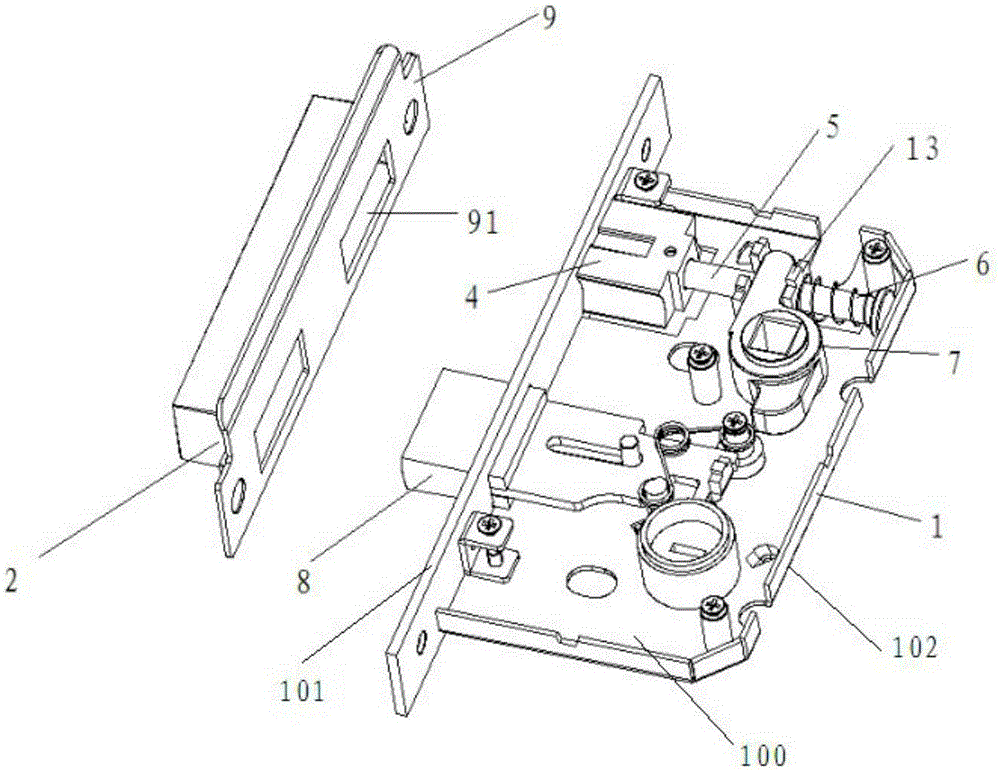

Magnetic noiseless lock

InactiveCN105421898ASimple structureReduce manufacturing costNon-mechanical controlsEngineeringMagnet

The invention provides a magnetic noiseless lock. The magnetic noiseless lock comprises a lock body and a spring bolt box, wherein the lock body comprises a first magnet, a spring bolt, a pulling rod, a returning spring and a shifting fork; the spring bolt box comprises a lock catch, a second magnet arranged in the lock catch, and a muffling block arranged on the outer surface of the second magnet; the second magnet is fixed to a position corresponding to the first magnet along the length direction of the spring bolt box; the spring bolt is provided with a first position where the spring bolt can retract in the lock body, and a second position where the spring bolt can extend out of the lock body and be embedded into the spring bolt box. According to the magnetic noiseless lock, the magnets are additionally arranged based on a common lock, and a muffler is arranged, so that the muffling effect is achieved; the whole magnetic noiseless lock is simple in structure, and the manufacturing cost is not increased by being compared with that of the common lock; in addition, the arrangement positions of the magnets are changed, so that the service lives of the magnets can be prolonged, and as a result, the service life of the whole noiseless lock can be prolonged; the extra cost of replacing the lock due to the additionally-arranged magnets can be decreased.

Owner:FOSHAN HUTLON INTELLIGENT TECH CO LTD

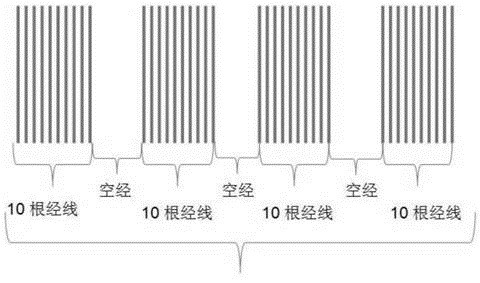

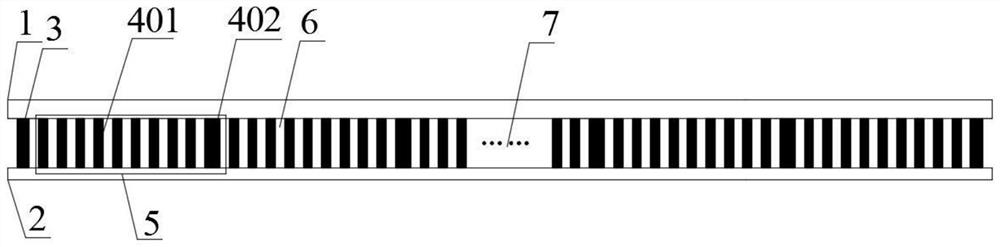

Preparation method of cord fabric with multiple groups of hollow warp marking structures and cord fabric prepared by preparation method

PendingCN111636129ASolve uneven density distributionImprove securityLoomsHeating/cooling textile fabricsAir-jet loomEngineering

The invention discloses a preparation method of a cord fabric with multiple groups of hollow warp marking structures and the cord fabric prepared by the preparation method. The preparation method comprises the following steps of: firstly, preparing cord threads in an S twisting direction and a Z twisting direction; secondly, crossly arranging the cord threads in the S twisting direction and the cord threads in the Z twisting direction, and preparing a grey fabric through an air jet loom provided with a reed; and carrying out gum dipping treatment to obtain the cord fabric with the multiple groups of hollow warp marking structures. According to the preparation method disclosed by the invention, reed teeth with different thicknesses are regularly arranged in the reed; the cord threads in theS twisting direction and the Z twisting direction are regularly arranged, so that the prepared cord fabric has a hollow warp effect and keeps clear hollow warp marks; the problem that the density distribution of the cord threads is not uniform is radically solved; and the uniformity and consistency of the strength of a tire cap ply are ensured and the safety of tire utilization is improved.

Owner:PINGDINGSHAN SHENMA TIRE CORD FABRIC DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com