Modular refrigeration unit and process for assembling a modular refrigeration unit to a cabinet of a refrigeration appliance

A refrigeration device and refrigeration equipment technology, which is applied to household refrigeration devices, lighting and heating equipment, cooling fluid circulation devices, etc., can solve the problems of reinforcement, difficulty in achieving airtight isolation, and inability to install refrigeration devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

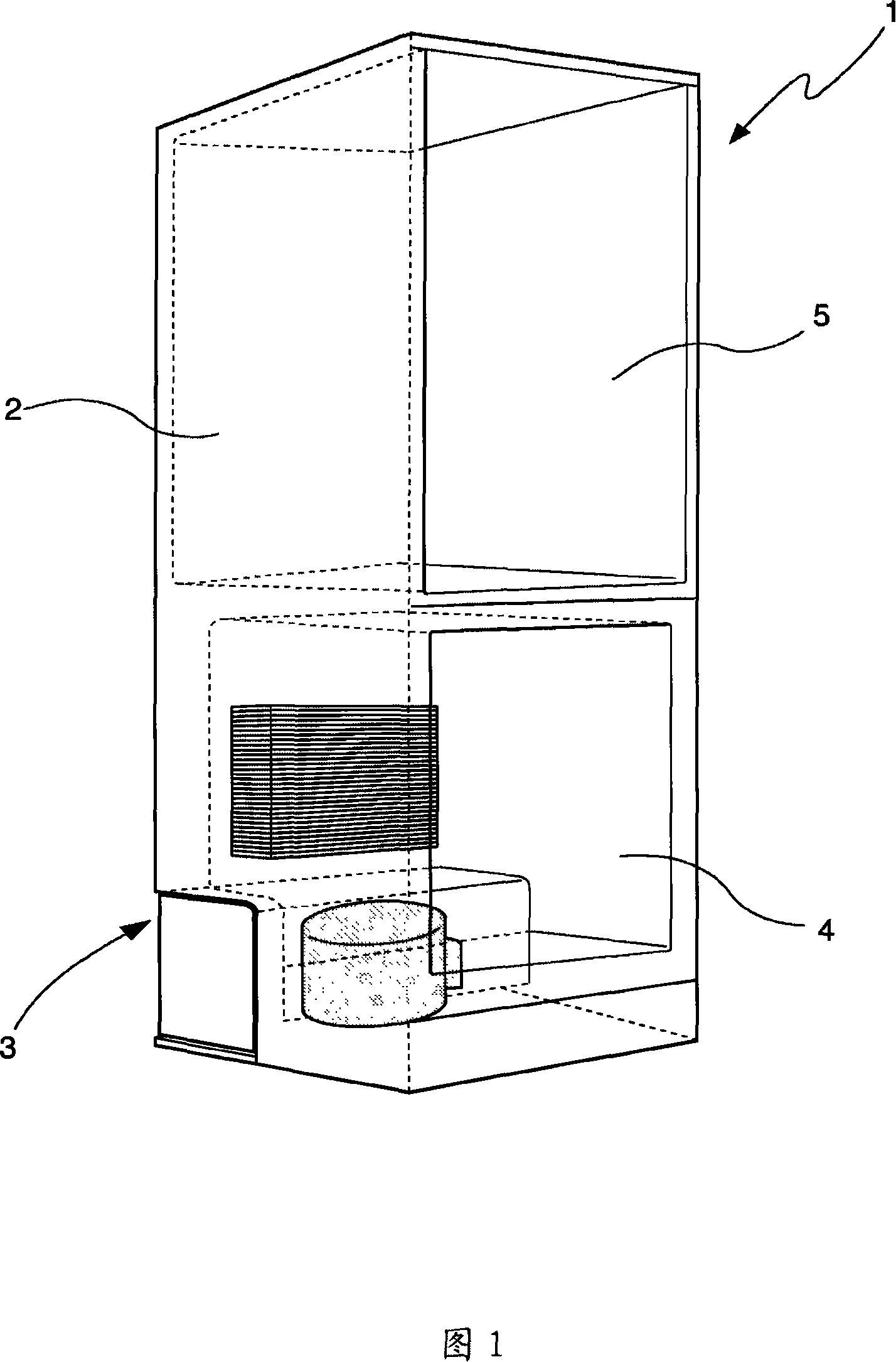

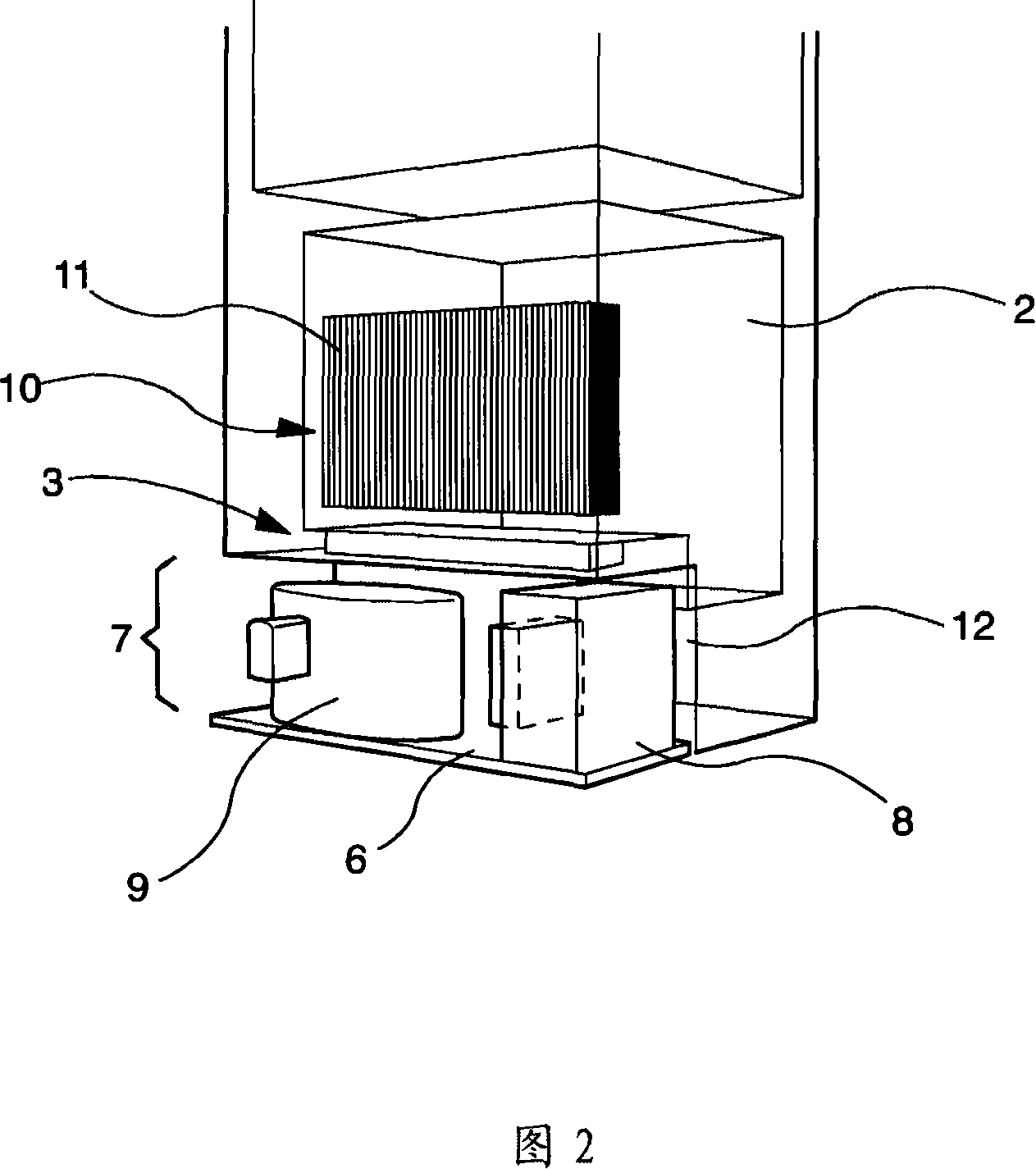

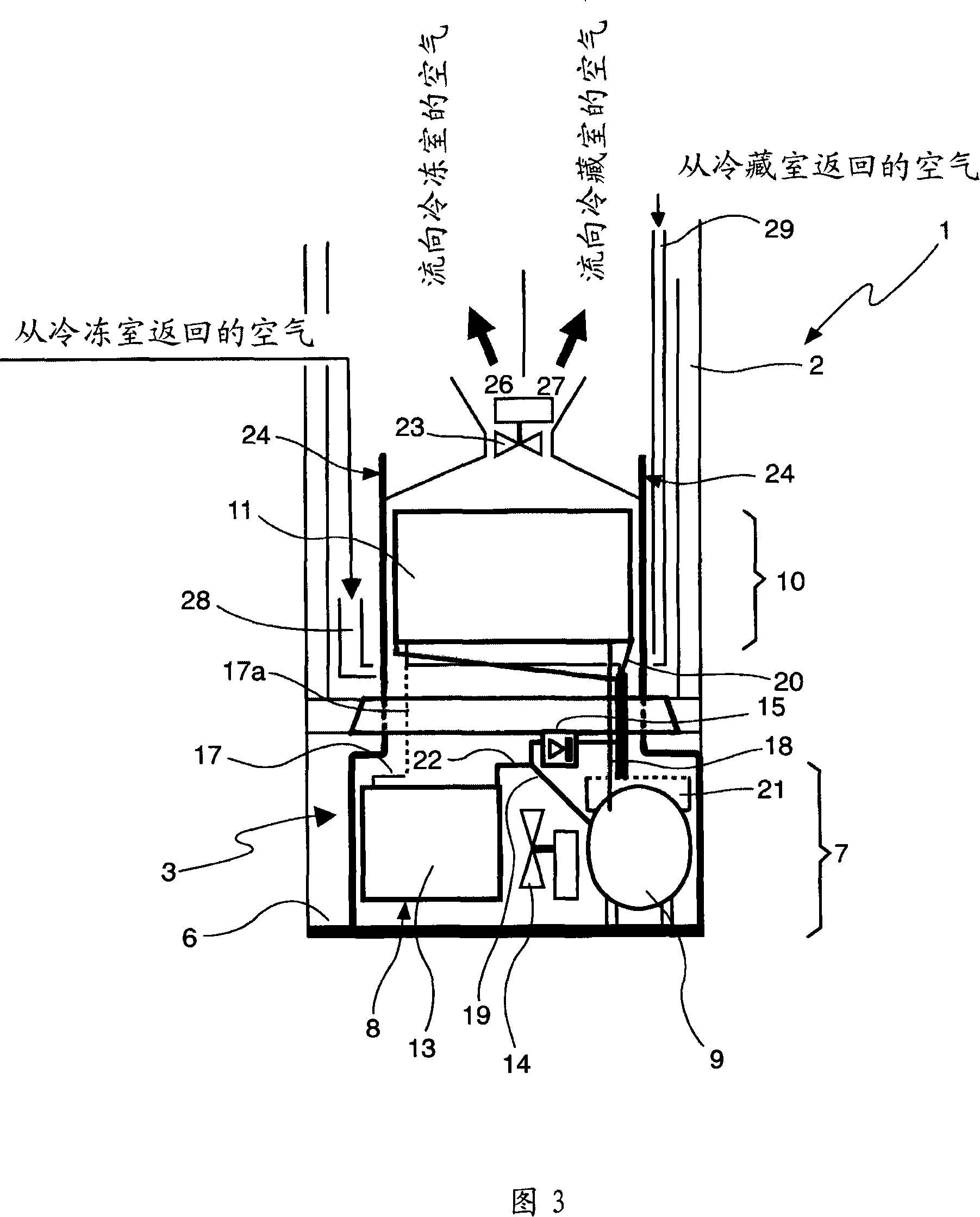

[0030] Referring to the above-mentioned drawings, the refrigeration equipment 1 includes an isolated cabinet 2 and a modular refrigeration device 3 ; the cabinet 2 includes one or more food storage compartments, such as a freezer compartment 4 and a refrigerator compartment 5 . The modular refrigeration device 3 includes a base plate 6 for supporting a condensing assembly 7 including a condensing device 8 and a compressor 9 , and an evaporating assembly 10 including an evaporator 11 . As will be described in more detail below, the modular refrigeration unit 3 is mounted to the lower rear of the cabinet 2 where a recess 12 in the cabinet 2 accommodates the condensing assembly 7 .

[0031] Figures 3 and 4 show operational diagrams of a refrigeration plant 1 provided with a modular refrigeration unit 3 with no-frost characteristics; in this case the condensing assembly 7 comprises a dynamic condenser 13 with a fan 14 And a defrosting device, such as a hot gas defrosting pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com