Low internal reflection composite base material and manufacturing method thereof

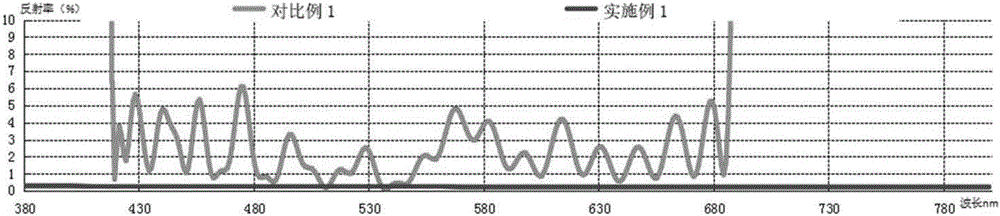

A composite substrate, internal reflection technology, applied in optics, instruments, optical components, etc., can solve the problems of imaging quality, increased internal reflection of the substrate, damage to the coating structure, etc., to achieve increased complexity, simple manufacturing process, The effect of increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

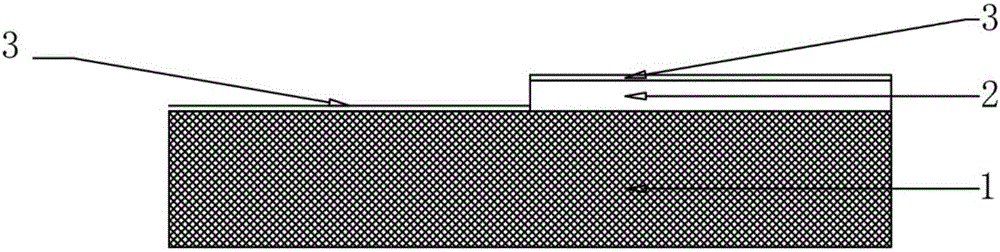

Image

Examples

Embodiment 1

[0032] 1) Coating optical black ink on the designated area of the glass substrate;

[0033] 2) After the ink is cured, move the substrate to a vacuum coating machine for coating treatment to obtain a low internal reflection substrate with a shielding layer.

Embodiment 2

[0035] 1) Coating optical black ink on the designated area of the sapphire glass substrate;

[0036] 2) After the ink is cured, PVD coating treatment is performed on the base material to obtain a low internal reflection base material with a shielding layer.

Embodiment 3

[0038] 1) Coating optical black ink on the designated area of the glass substrate;

[0039] 2) After the ink is cured, the substrate is subjected to CVD coating treatment to obtain a substrate with a low internal reflection with a shielding layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com