Dressing glass

A technology for vanity mirrors and mirror bases, applied in the field of vanity mirrors, can solve the problems of increasing costs and the thickness of vanity mirrors cannot be thinner, and achieve the effect of increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

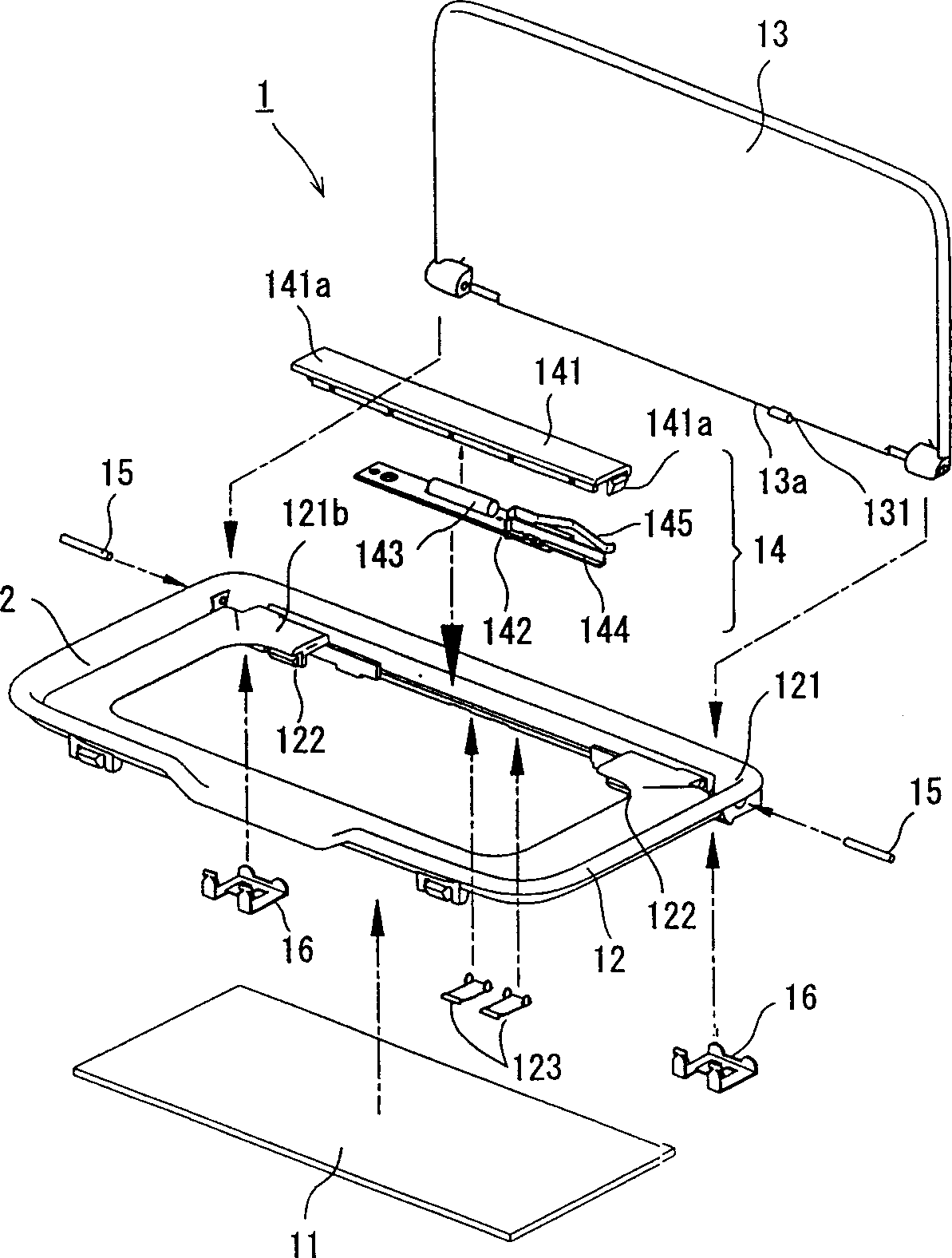

[0034] So far, the above description is given based on the embodiment, in which the base plate 142 is detachably fixed on the lens plate 141 with screws. The present invention is not limited to this embodiment. The lens plate may be provided with an engaging protrusion. The engaging protrusion can be elastically engaged with the hole in the base plate 142, so that the lens plate and the base plate are detachably connected to each other.

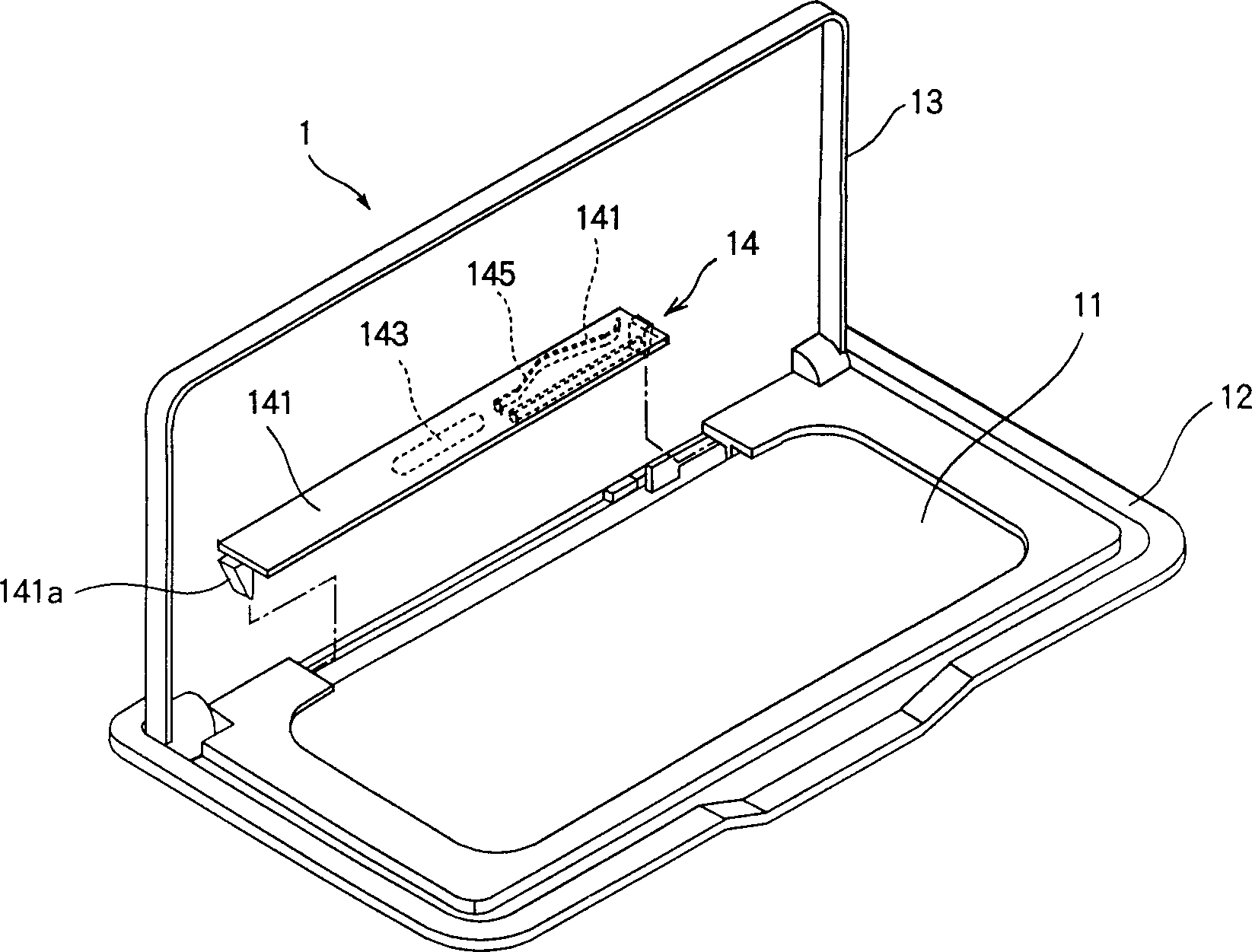

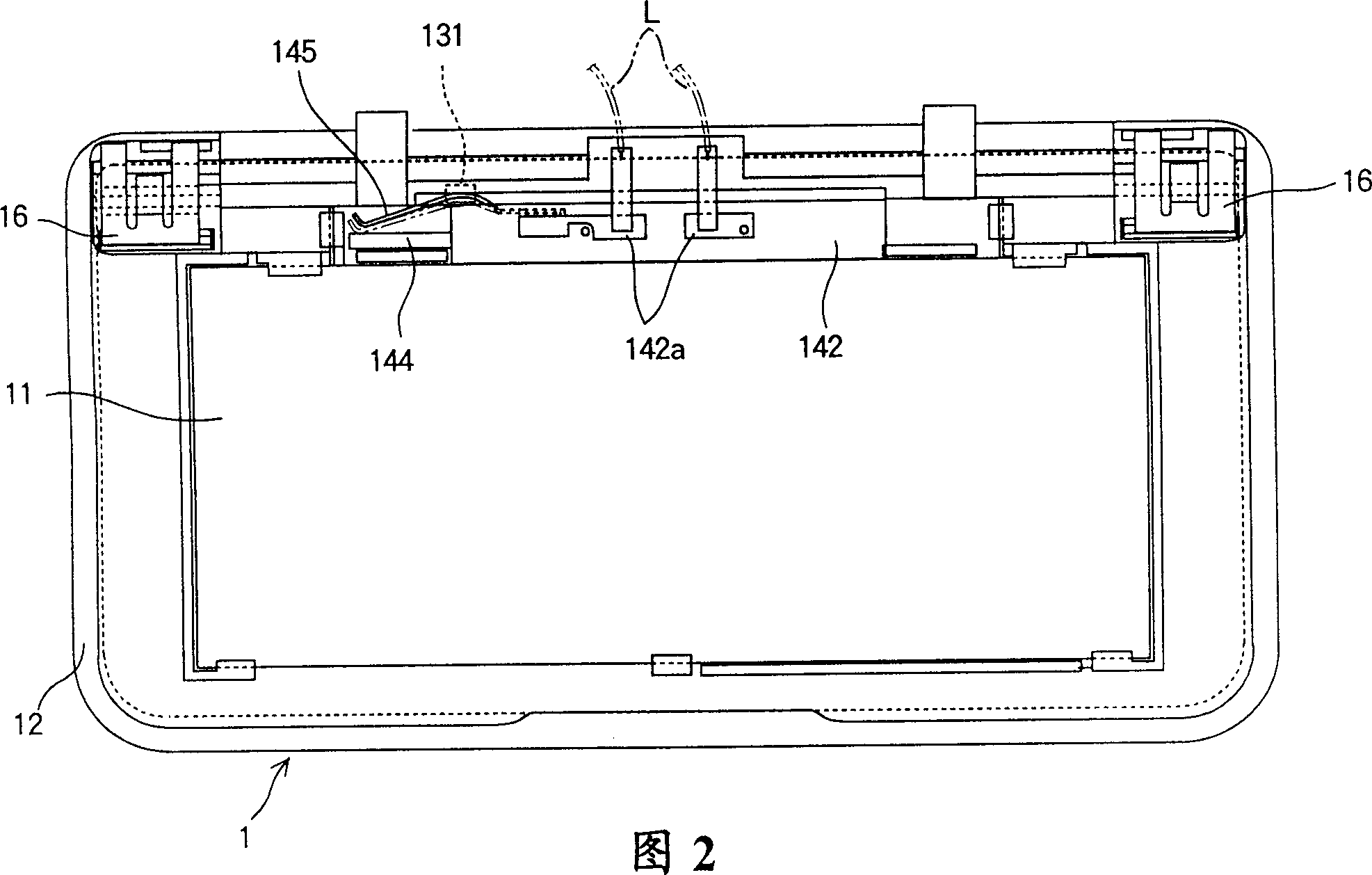

[0035] As explained above, this invention includes: a mirror holder mounted with a mirror; a mirror cover that is openably connected to the mirror holder through a loose leaf; and a mirror cover that is connected and disconnected by opening and closing the mirror cover The switch; a substrate on which the switch is mounted; a lighting device mounted with a lamp, the lamp is connected to the wires drawn from two opposite ends of the substrate; and a substrate that can be freely connected to the substrate Or the disassembled lens plate. Since the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com