Preparation method of cord fabric with multiple groups of hollow warp marking structures and cord fabric prepared by preparation method

A technology of cord fabrics and dipped cord fabrics, applied in textiles, looms, fabrics, etc., can solve the problems of inconsistent number of cords, lack of safety, hidden safety hazards, etc., to solve uneven density distribution and ensure uniformity Sexuality, increase the effect of uniform consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

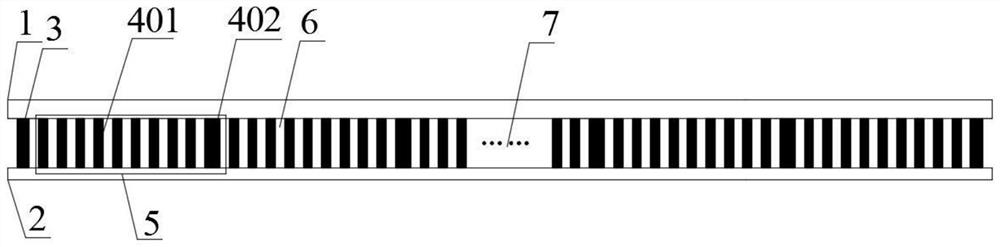

[0045] A kind of steel reed for preparing multiple groups of air warp marking structure cord fabrics, such as figure 1 , image 3 As shown, the reed includes an upper beam 1 and a lower beam 2 parallel to each other, and also includes reed teeth 4 and reed holes 6 between every two adjacent reed teeth; the reed teeth are vertically arranged on the upper beam and the lower beam Between the lower beams, and the two ends of the reed teeth are fixedly connected with the upper beam and the lower beam respectively, and bonded together by gluing; one side of the reed teeth body is provided with a weft thread groove 403 (all the reed teeth sides are grooves are provided, and all grooves are at the same height of the reed teeth.);

[0046] The reed teeth include a thin reed tooth 401 with a diameter of A mm and a thick reed tooth 402 with a diameter of B mm; wherein nine adjacently arranged thin reed teeth 401 and one thick reed tooth 402 are arranged adjacently to form a group of ree...

Embodiment 2

[0052] A kind of steel reed for preparing multiple groups of air warp marking structure cord fabrics, such as figure 2 , image 3 As shown, the reed includes an upper beam 1 and a lower beam 2 parallel to each other, and also includes reed teeth 4 and reed holes 6 between every two adjacent reed teeth; the reed teeth are vertically arranged on the upper beam and the lower beam Between the lower beams, and the two ends of the reed teeth are fixedly connected with the upper beam and the lower beam respectively, and bonded together by welding; one side of the reed teeth body is provided with a weft thread groove 403 (all reed teeth sides are provided with have grooves and all grooves are at the same height of the reed teeth.);

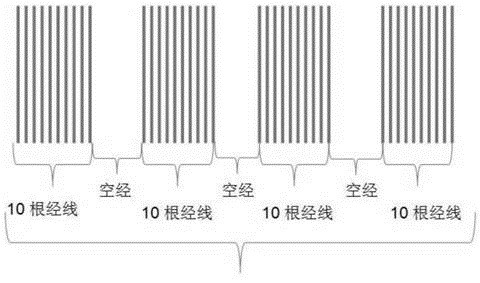

[0053] The reed teeth include a thin reed tooth 401 with a diameter of A mm and a thick reed tooth 402 with a diameter of B mm; ten adjacent thin reed teeth 401 and one thick reed tooth 402 are arranged adjacently to form a group of reeds Teeth 8, a tot...

Embodiment 3

[0058] A method for preparing a cord fabric with a plurality of sets of air warp marking structures, comprising the following steps:

[0059] (1) twisting:

[0060] Get 1440 pieces of nylon 66 with a fineness of 940dtex and place them in the twisting machine, control the rotating spindle to rotate to the right, and prepare 720 cords in the S twist direction (every 2 nylon 66 filaments prepare a curtain in the S twist direction line), put it aside; then take 1440 pieces of nylon 66 with a fineness of 940dtex and place them in the twisting machine, control the rotating spindle to rotate to the left, and prepare 720 cords in the Z twist direction (prepared by every 2 nylon 66 filaments) Take out a Z-twisted cord) and put it aside;

[0061] (2) Weaving:

[0062] With the viscose yarn as the weft, place the S-twisted cords and Z-twisted cords prepared in step (1) on the large creel in sequence, and then pass through the wire guide plate→filament collecting plate→splitting bar in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com