Electronic component mounting apparatus

An electronic component installation and electronic component technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of the expansion of the moving area, the deterioration of the efficiency, and the deterioration of the efficiency of the mounted electronic components, so as to suppress the increase in size and production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, preferred modes for implementing the present invention (hereinafter referred to as embodiments) will be described in detail with reference to the drawings. In addition, this invention is not limited by the following embodiment. In addition, each component included in the following embodiments includes configurations that can be easily conceived by those skilled in the art, substantially the same configurations, and configurations within the so-called equivalent range. In addition, components disclosed in the following embodiments may be appropriately combined.

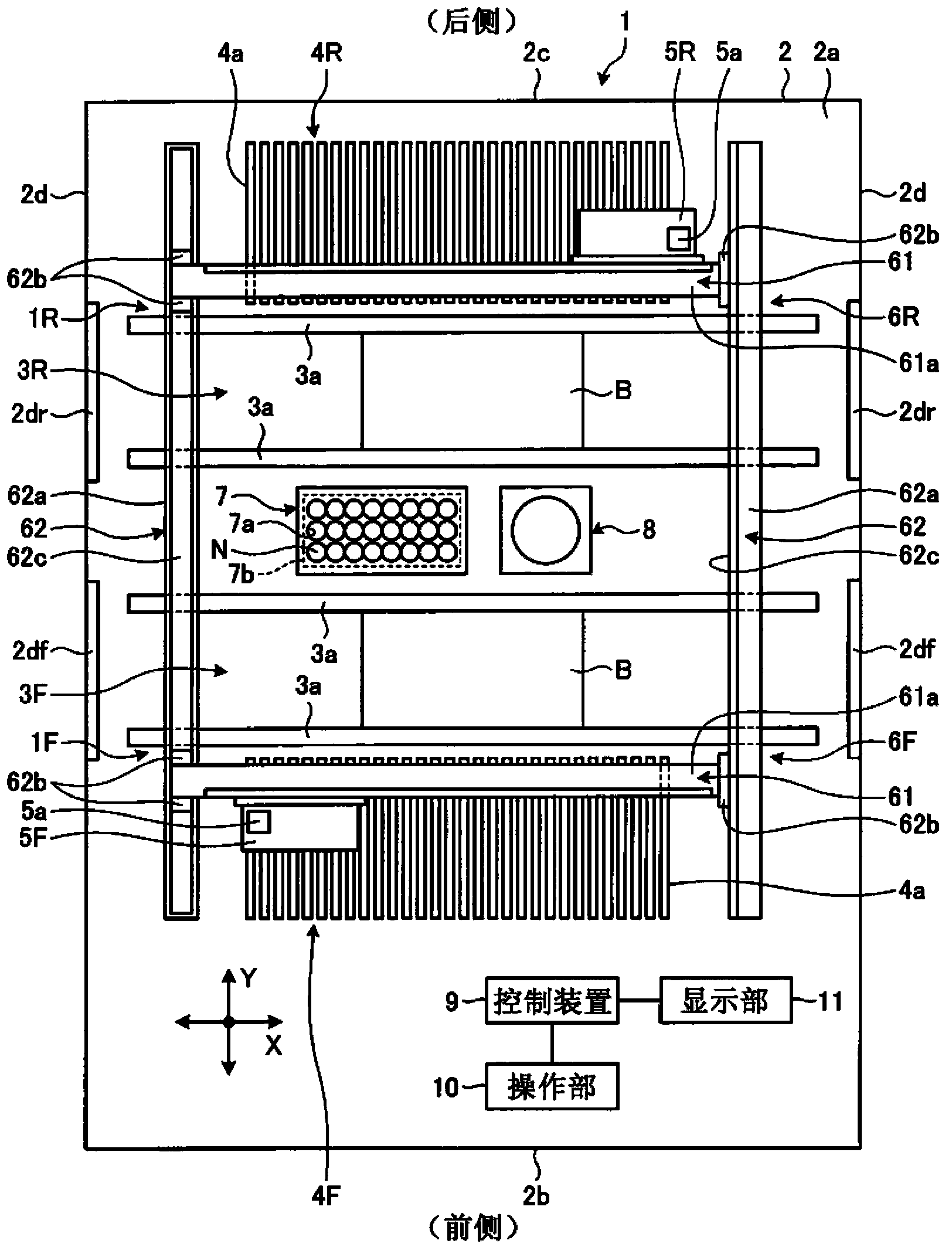

[0055] figure 1 It is a schematic plan view showing the schematic configuration of the electronic component mounting apparatus 1 according to the embodiment of the present invention.

[0056]The electronic component mounting apparatus 1 is an apparatus for mounting electronic components on the board B. As shown in FIG. The electronic component mounting apparatus 1 is arranged on the frame body 2:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com