Middle rod adding method of guide rail type drilling device

A drilling device and rail-type technology, applied to drilling equipment and methods, drill pipes, rotary drilling rigs, etc., can solve problems such as the difficulty of adding rods in the middle, and achieve the advantages of easy popularization and application, simple operation, and increased production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

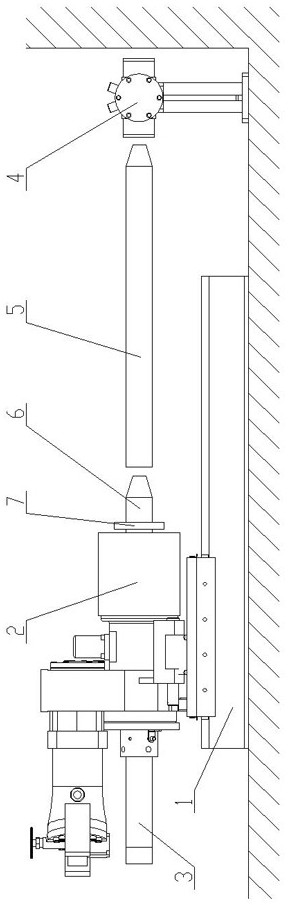

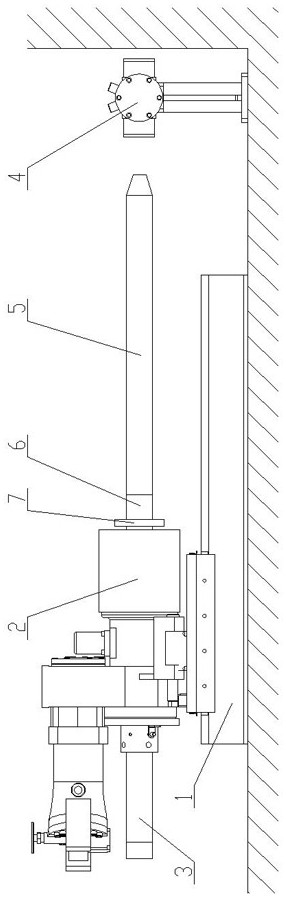

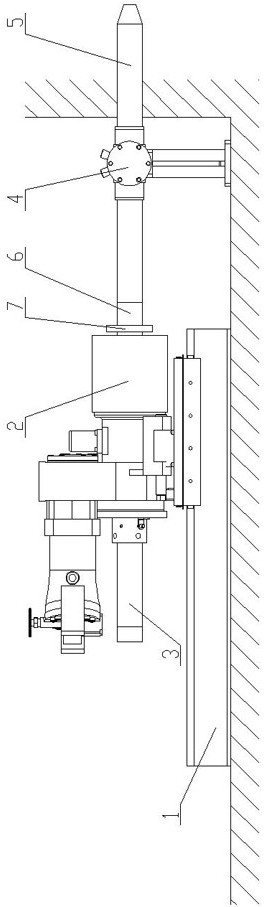

[0024] Referring to the accompanying drawings, the specific implementation is as follows:

[0025] The invention provides a method for adding rods in the middle of a guide rail type drilling device. The guide rail type drilling device includes a section of guide rail 1, on which a power head 2 for clamping a drill pipe 5 is installed, and the power head 2 is far away from the hole to be drilled. A cooling water input device 3 is installed on one side of the wall. When the stroke of the power head 2 moving on the guide rail 1 is less than the length of the drill rod 5, it is difficult to add intermediate rods to the drill rod 5. In this embodiment, the intermediate rod addition to the drill rod 5 can be realized through the following method steps:

[0026] Step 1. Drill pipe installation

[0027] Such as Figure 1-2 As shown, the holder 4 is pre-installed between the guide rail 1 of the drilling device and the wall to be drilled, usually the holder 4 is directly placed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com