Wing structure

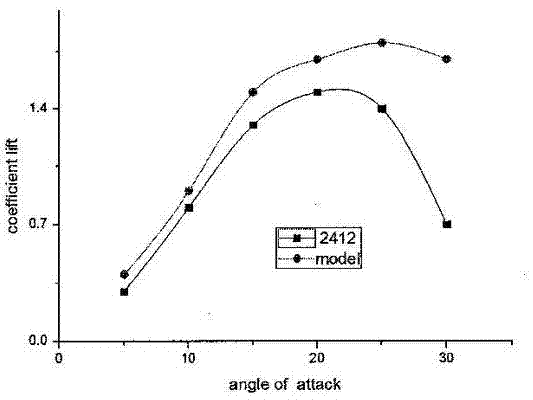

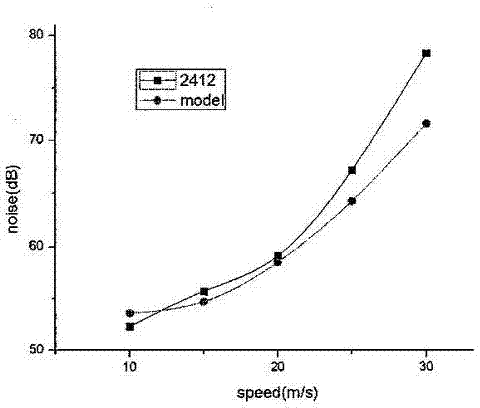

A wing structure and wing technology, applied in the direction of the wing shape, etc., can solve the problems such as the unsatisfactory aerodynamic performance of the airfoil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

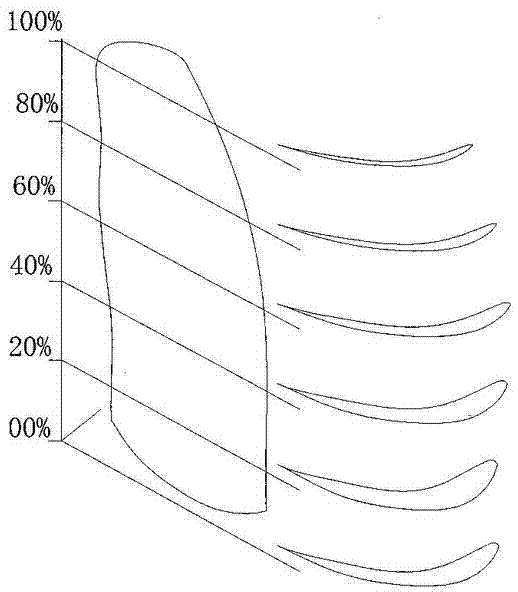

[0032] The present invention is constituted continuously by airfoil section,

[0033] The airfoil sections are respectively 0%, 20%, 40%, 60%, 80%, and 100% span length from the root of the wing. The coordinates of the above airfoil are given by the coordinate method, such as image 3 with Figure 4 As shown, the thickness of the airfoil gradually decreases from the root (0%) to the end (100%), and the camber of the airfoil also gradually decreases. The width of the airfoil is slightly smaller at the root and end, and slightly larger in the middle of the airfoil.

[0034] The ratio of wingspan to chord length (aspect ratio) is 5.50 to 7.24;

[0035] The chord length refers to the standard average chord length SMC=S / b, wherein S is the wing area, and b is the span length.

[0036] The leading edge of the wing is a high degree curve approximately parabolic:

[0037] 2x / b=-2.3ξ5+3.752ξ4-1.942ξ3+0.192ξ2+0.077ξ-0.003.

[0038] Among them: 2x / b is the chord ratio, ξ=2y / b is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com