Measuring tool and method for measuring size of large-excircle workpiece by adopting same

A measuring tool and size technology, applied in the field of measuring tools, can solve the problems of being easily affected by ambient temperature, troubled by the quality of production and processing parts, and errors in vernier calipers, and achieve the effect of simple structure, consistent real-time status, and accurate measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

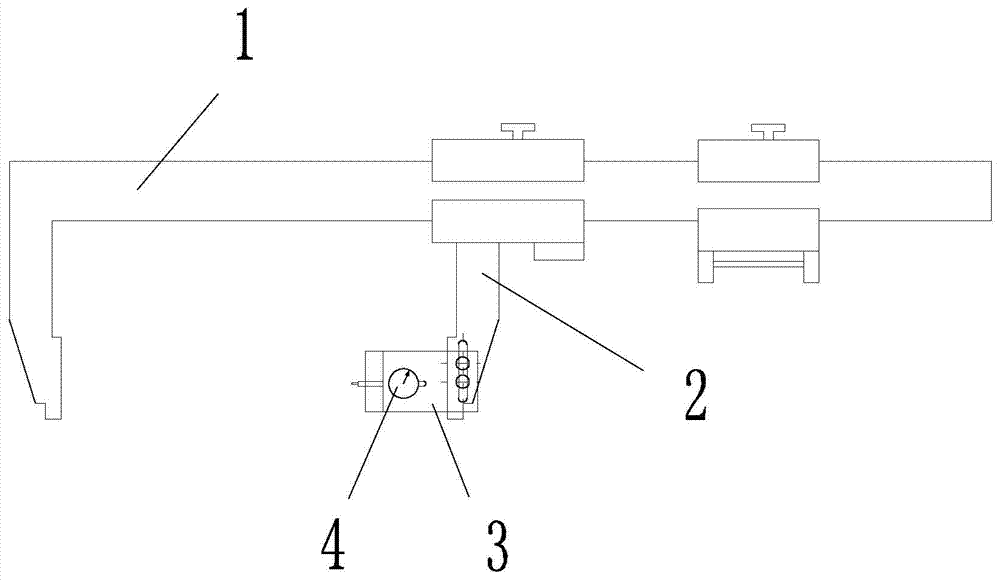

Image

Examples

Embodiment 1

[0034] Embodiment one, select the standard part, the size of the standard part measured by the three-coordinate measuring machine is 15.255mm, then measure the standard part with a measuring tool, the millimeter scale A on the main ruler 1 is measured to be 35mm, and the graduation scale B is 50mm (ie 0.50mm), use this measuring tool to continue to measure the outer circle of the workpiece to be measured, record the millimeter scale C on the main ruler 1 as 35mm, and record the graduation scale D of the dial indicator 4 as 65 (0.65mm); at this time The millimeter scale A and the millimeter scale C are equal to 35mm, then calculate the difference E between the graduation scale D and the graduation scale B, and the calculated difference E is 0.65mm-0.50mm=0.15mm, then the processing to be tested The size of the piece is the size of the standard piece plus the resulting difference E, that is, 15.255mm+0.15mm=15.405mm.

Embodiment 2

[0035] Embodiment two, select the standard part, the size of the standard part measured by the three-coordinate measuring machine is 15.255mm, then measure the standard part with a measuring tool, and the millimeter scale A on the main chi 1 is measured to be 35mm, and the graduation scale B is 50 (ie 0.50mm), use this measuring tool to continue to measure the outer circle of the workpiece to be measured, record the millimeter scale C on the main scale 1 as 36mm, and record the graduation scale D of the dial indicator 4 as 65 (0.65mm); at this time The millimeter scale A and the millimeter scale C are not equal, then calculate the difference F between the millimeter scale C and the millimeter scale A, that is, the difference F=36mm-35mm=1mm, the difference between the graduation scale D and the graduation scale B Value E, that is, the difference E=0.65mm-0.50mm=0.15mm, then the size of the processing to be measured is the size of the standard part plus the resulting difference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com