Printed wiring board, printed wiring board assembly, method for manufacturing printed wiring board, and illuminating apparatus

A technology for printed wiring boards and manufacturing methods, applied in printed circuit manufacturing, printed circuits, printed circuits, etc., capable of solving problems such as reduced light reflection efficiency, surface damage, and attached dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] Hereinafter, an embodiment of the present invention will be described based on the drawings. In addition, the following embodiment is a case where the present invention is applied to a flexible printed wiring board. In addition, the present invention can also be applied to rigid printed wiring boards.

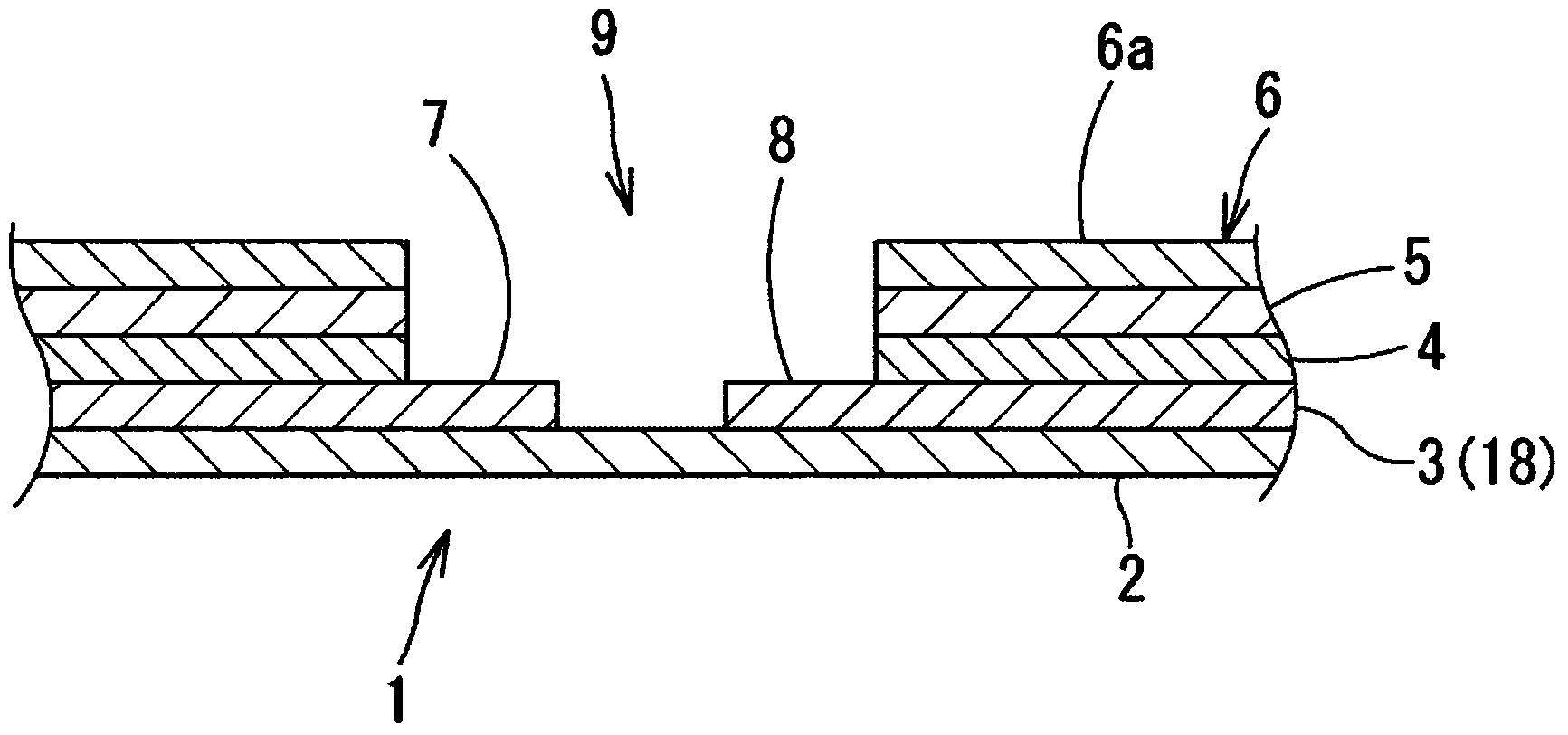

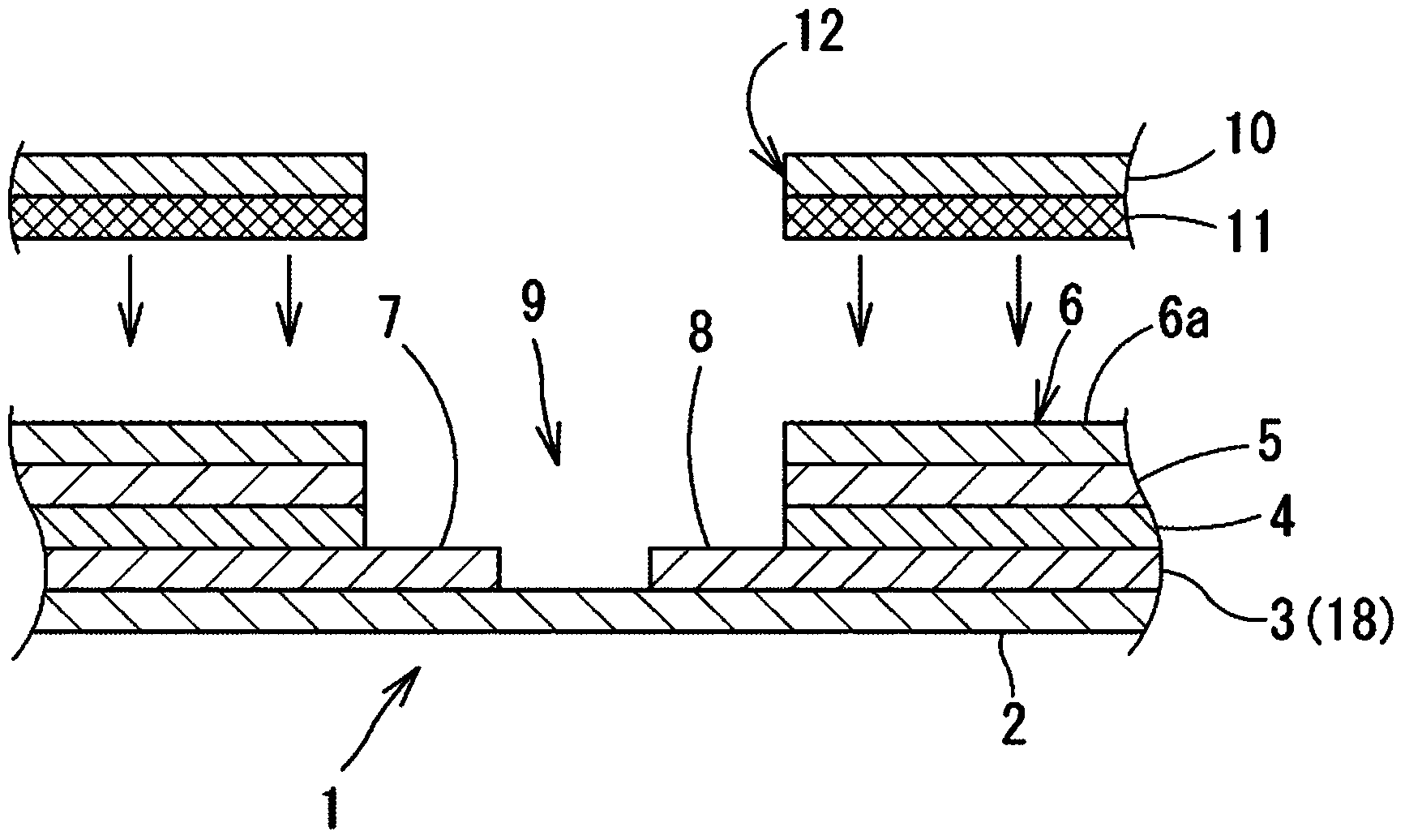

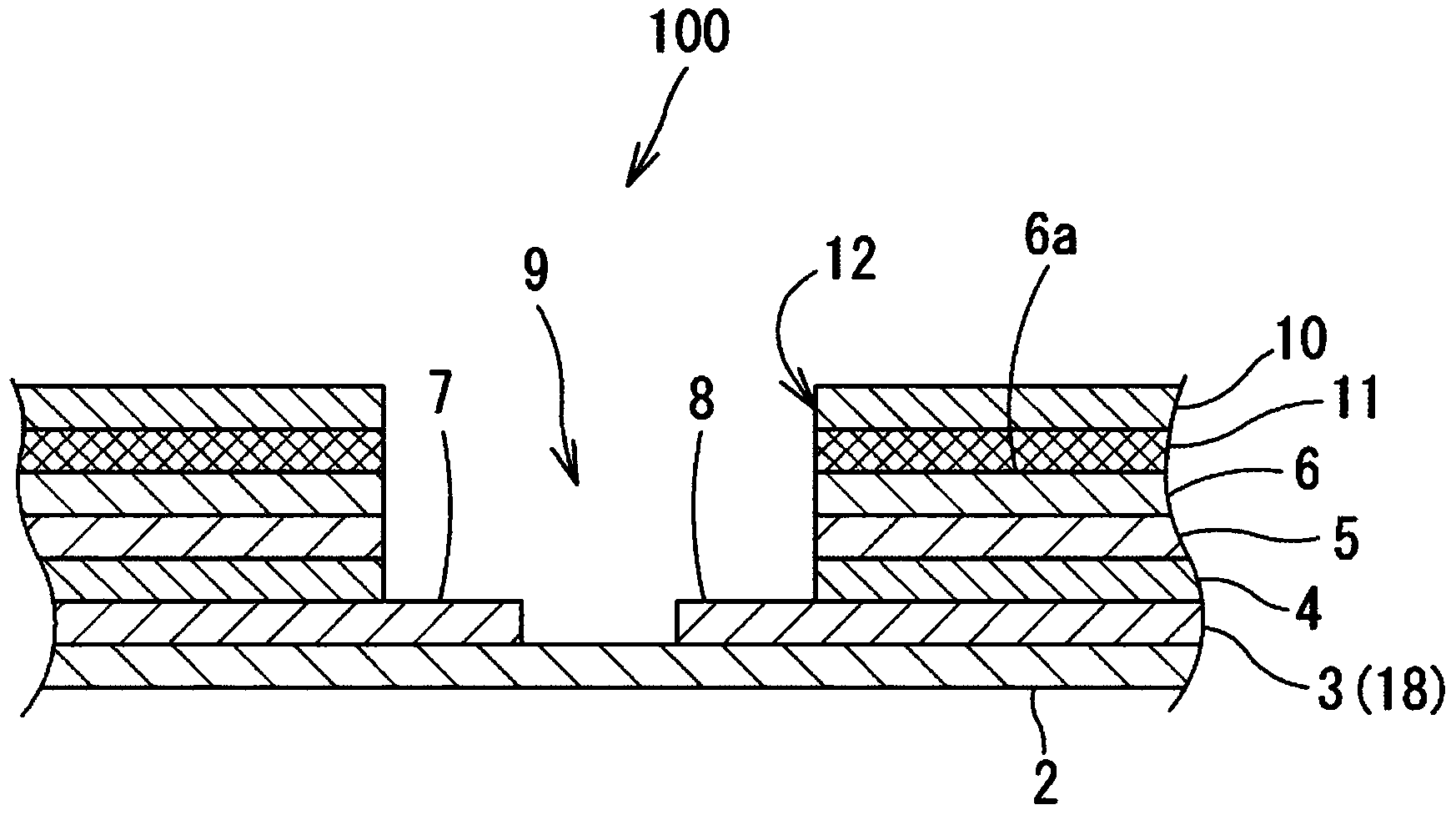

[0084] in figure 1 In the figure, the cross section of the flexible printed wiring board original board 1 for forming the flexible printed wiring board concerning this invention is shown.

[0085] figure 1 The flexible printed wiring board original board 1 shown in FIG. 1 is used to manufacture a plurality of flexible printed wiring boards for mounting LED light emitting elements. Although not shown, a plurality of conductive patterns 3 are formed on an insulating base material 2.

[0086] The above-mentioned flexible printed wiring board original board 1 is composed of the following parts: an insulating base material 2, which is formed of polyimide resin or the like; and a co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap