A plastic mold structure molding process

A molding process and die profile technology, applied in the field of automobile die stamping, can solve the problems of insufficient springback shaping effect, and achieve the effects of good springback elimination effect, easy pressing, safety and operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

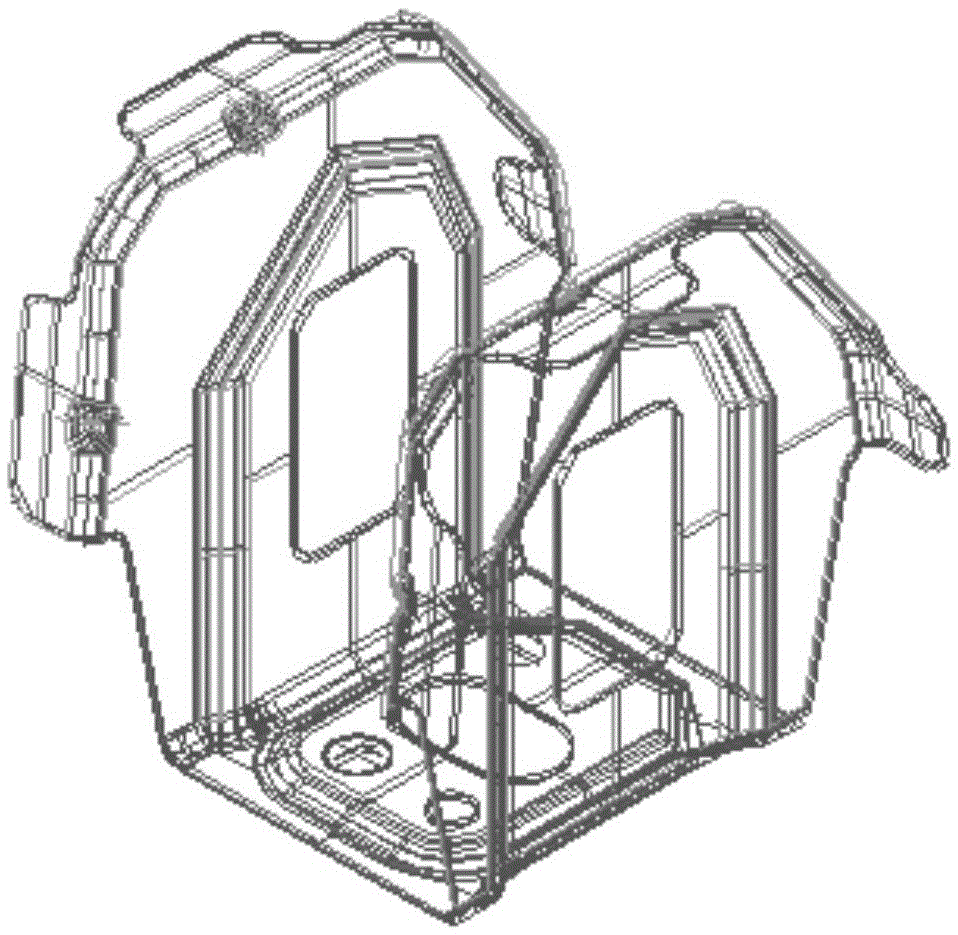

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

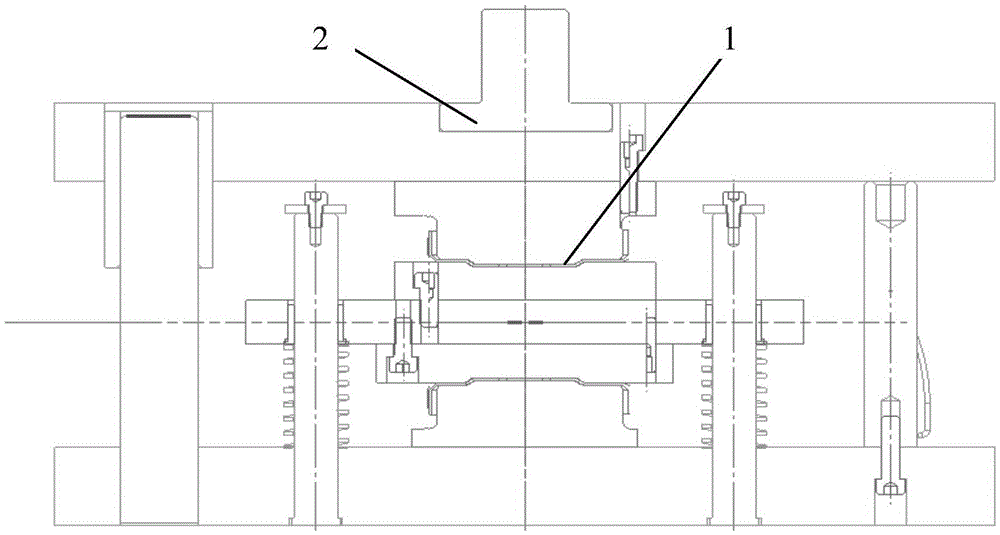

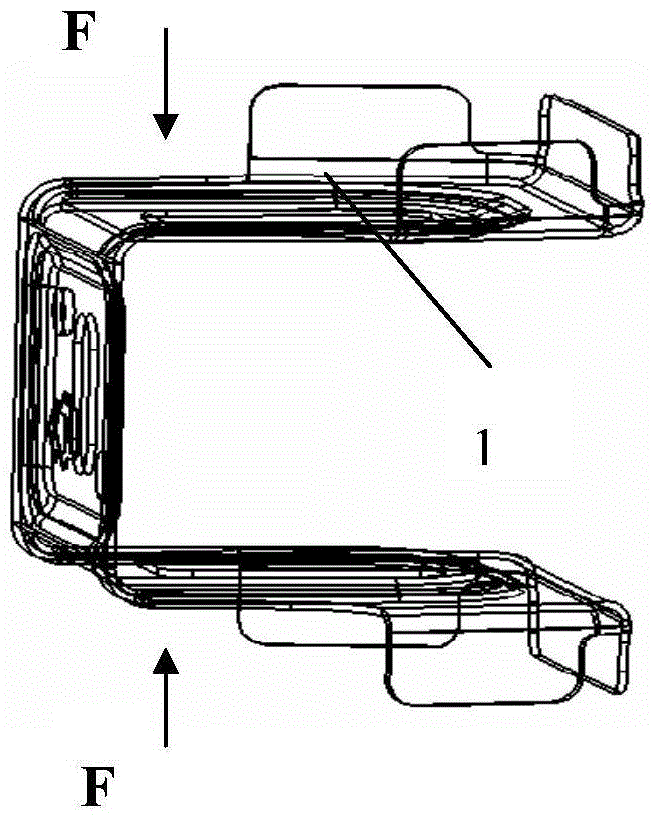

[0020] Such as figure 2 and image 3 As shown, a plastic mold structure molding process, including the first process is a blanking punching process; the second process is a flanging process; the third process is a flanging forming process; the fourth process is a shaping process;

[0021] This technical solution mainly changes and optimizes the above-mentioned structure and the mold structure similar to the above-mentioned shaping method and the feeding and feeding method of the part. The main purpose is to change the rebound shaping of this part from the side wall force to rotate the part by 90° After that, it is placed in the mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com