Connector mould

A connector and mold technology, applied in the field of connector molds, can solve problems such as poor sealing and leakage, and achieve the effects of long service life, reduced wear and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

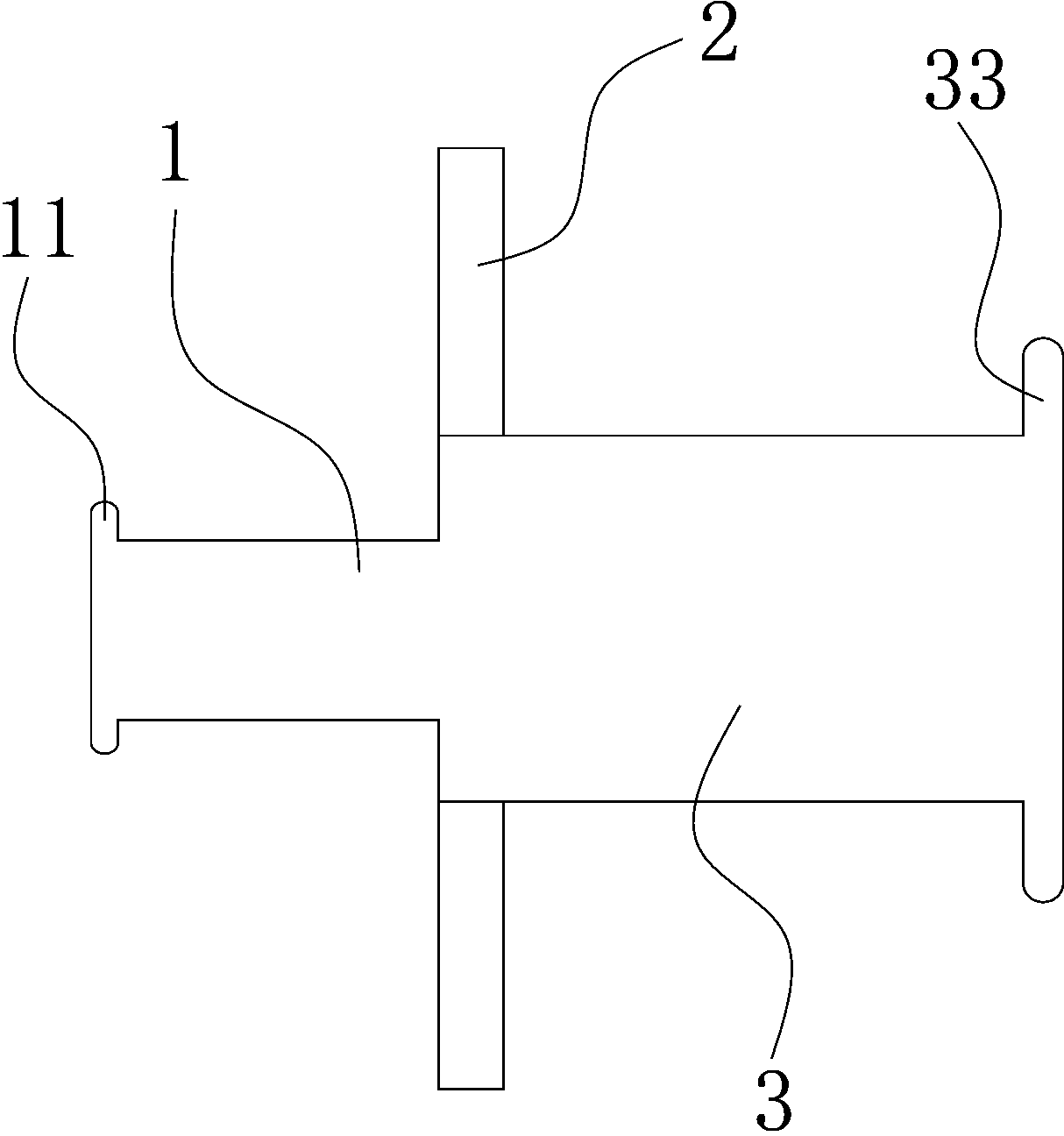

[0009] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 1 , a connector mold, the connector includes a connector body, the connector body is axially horizontal, has an opening at each of its axial ends, and a No. 1 flange is arranged on the connector body, the The two sides of the No. 1 flange are two connecting pipes with different diameters, which are used to connect the continuously rotating tubular object. The tubular object is specifically a part on the automobile and continuously rotates during use.

[0010] The mold comprises No. 1 mold 1, No. 2 mold 2 and No. 3 mold 3. The No. 1 mold 1 and the No. 3 mold 3 are hollow cylinders with openings at both ends. One side of the No. 1 mold No. 2 flange 11 is provided at the opening, and No. 3 flange 33 is provided at the opening on one side of the No. 3 mold 3. The diameter of the No. 1 mold 1 is less than the diameter of the No. 3 mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com